- Home » MATTRESS MACHINERY » Spring Manufacturing » Bonnell Spring Machine Series » Bonnell Spring Unit Production Line

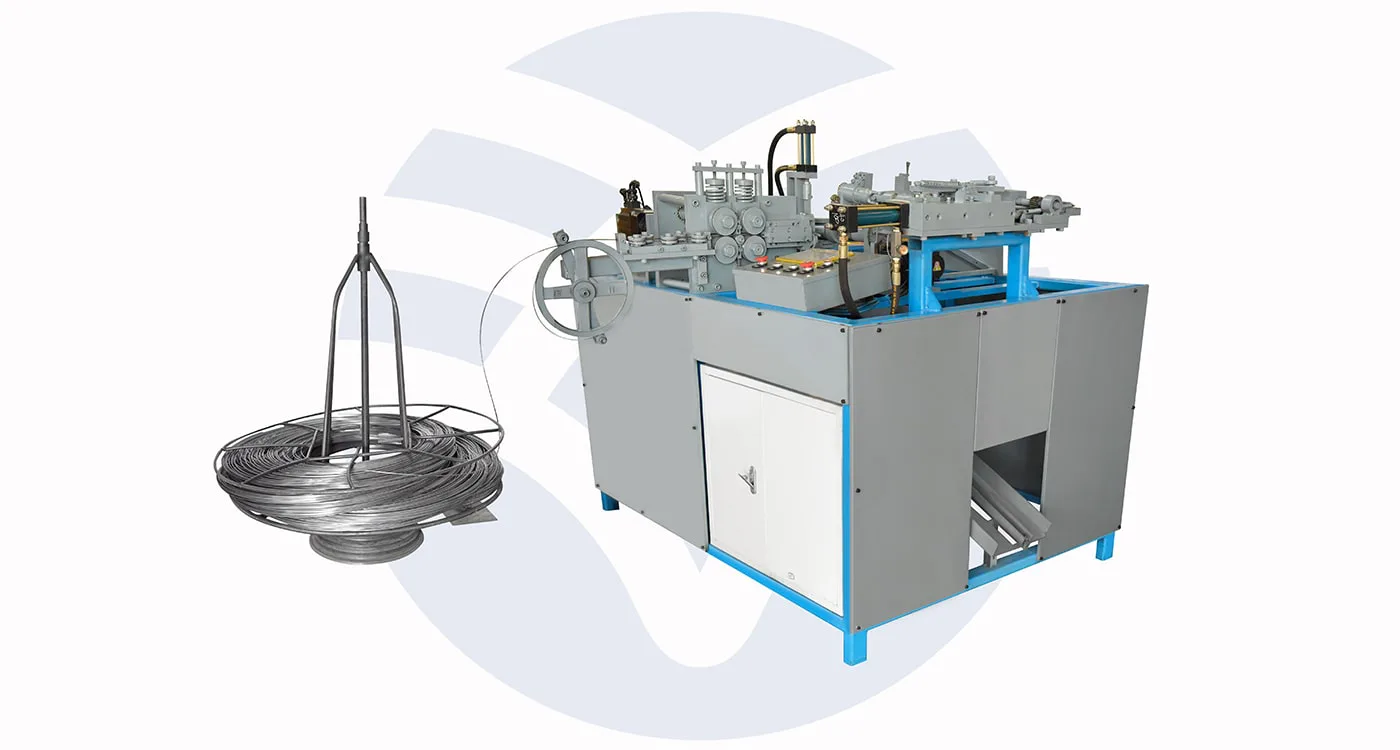

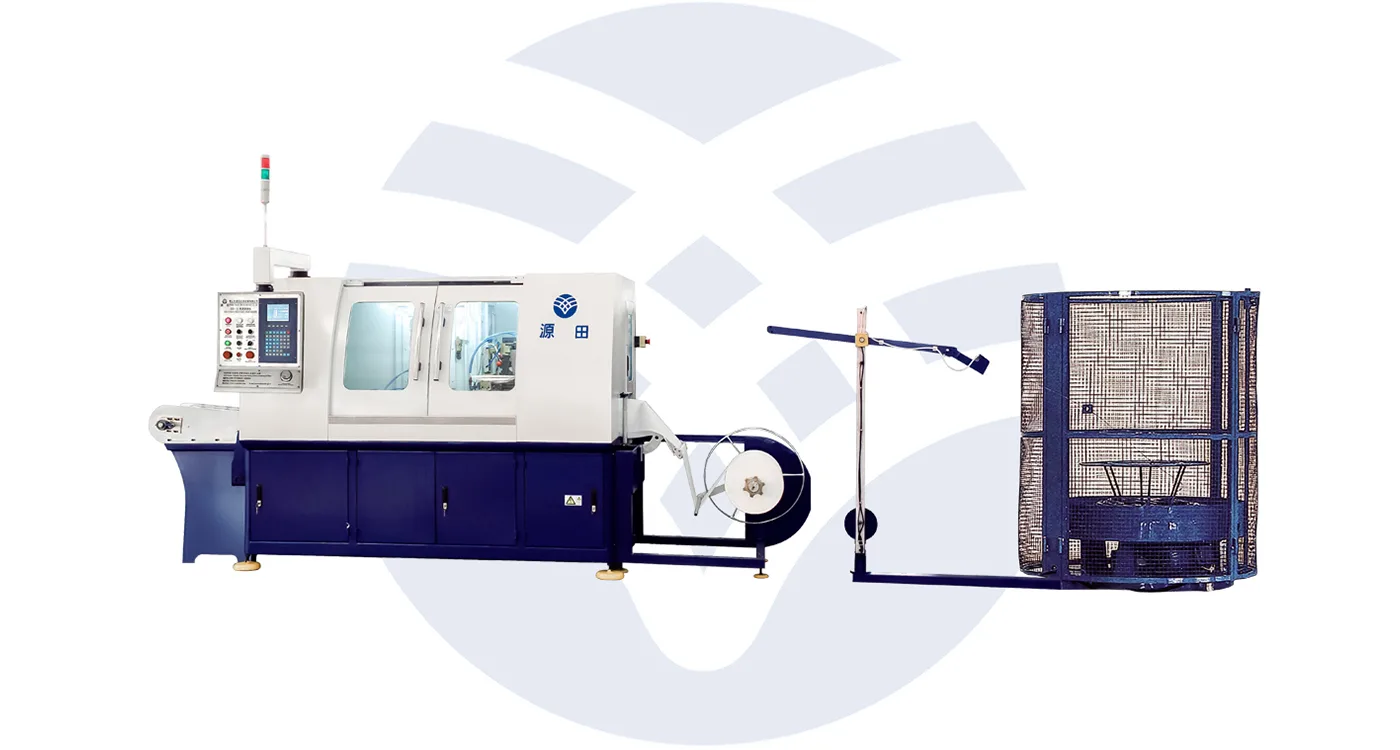

Bonnell Spring Unit Production Line YT-JCH-3

The YT-JCH-3 Bonnel Spring Unit Production Line is a highly – integrated machine in the field of spring unit production. It combines multiple functions, including wire feeding, spring coiling, knotting, wire arrangement, net – stacking mechanism, spring transportation, as well as netting and shaping. This integration enhances the coherence and efficiency of the production process, reduces manual intervention, and cuts labor costs. With a high level of automation, it can automatically net the springs, accurately cut the spring strings, and automatically tie both ends to ensure stable spring connections. The bed net can also move forward automatically for convenient follow – up operations. Moreover, the number of spring rows can be flexibly set according to specific customer requirements, meeting diverse needs in different production scenarios and providing great convenience and flexibility for spring product manufacturing.

1. The machine integrates functions of wire feeding, spring coiling, knotting, wire arranging, stacking mechanism, spring conveying, stringing, and shaping, etc.

2. Automatic stringing, automatic cutting of spring strings, automatic knotting at both ends, and automatic forward movement of the bed net. The number of spring rows can be set as required.

In terms of price, we have a special quotation sheet for each machine. At the same time, we can also provide professional mattress machinery solutions and quotations according to your manufacturing needs.

If you need more information about automatic eight-claws bonnell spring production line, please leave us a message, or contact our sales representative.

Parameters of YT-JCH-3

| Productivity | 7 – 17units/h | Spring End-Coil Diameter | φ65 – φ90mm |

| Max Coiling Productivity | 93pcs/min | Wire Diameter | φ2.0 – φ2.4mm |

| Power Supply | 3Ph380v50hz (Customizable as per customer requirements) | Spring Height/Turns | 4 Turns: 110 – 120mm, 5 Turns: 130 – 180mm 6 Turns: 150 – 180mm |

| Air Supply | 0.6 – 0.8Mpa | Wire Bobbin | Min Diameter 350mm, Max Diameter 1000mm |

| Total Power | 38kw | Installation Area | 8700×6600mm |