- Home » MATTRESS MACHINERY » Mattress Quilting » Flanging Machine Series » Flanging Machine+Air Blowing Table

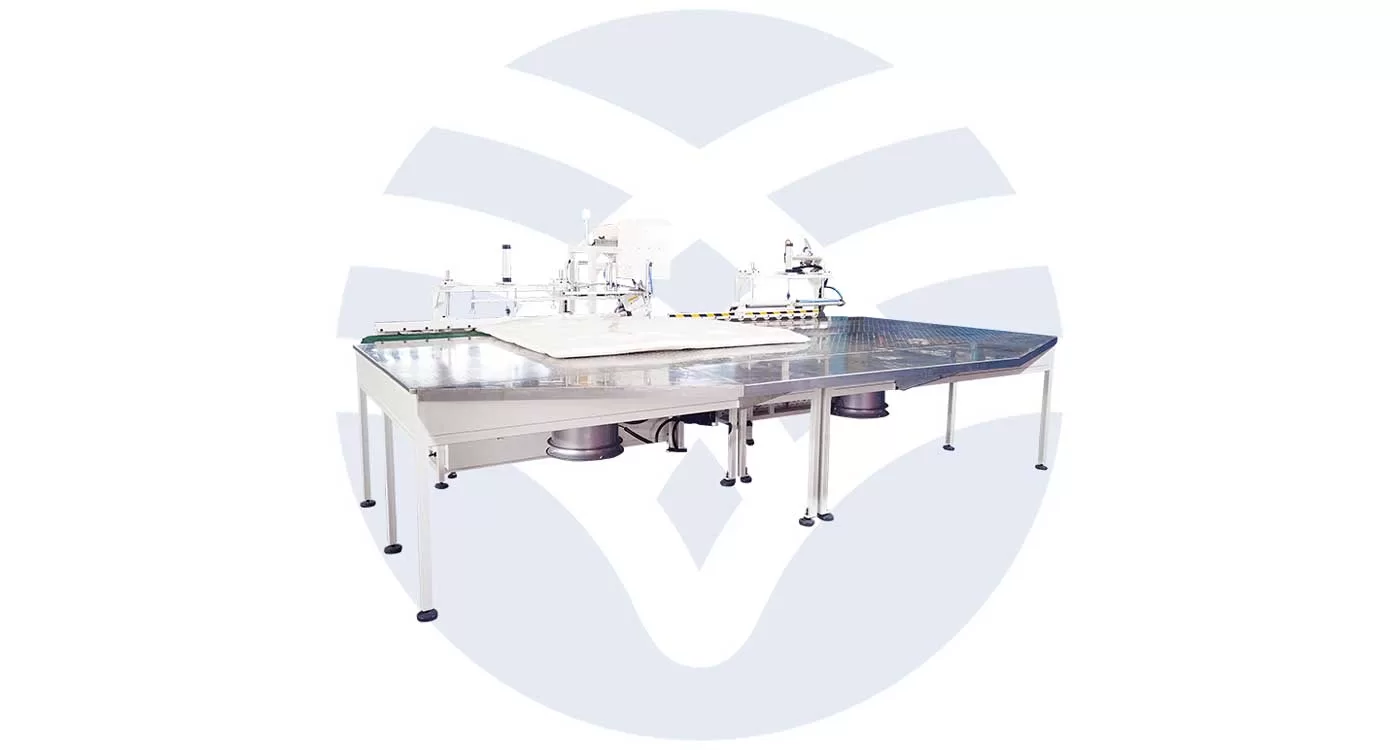

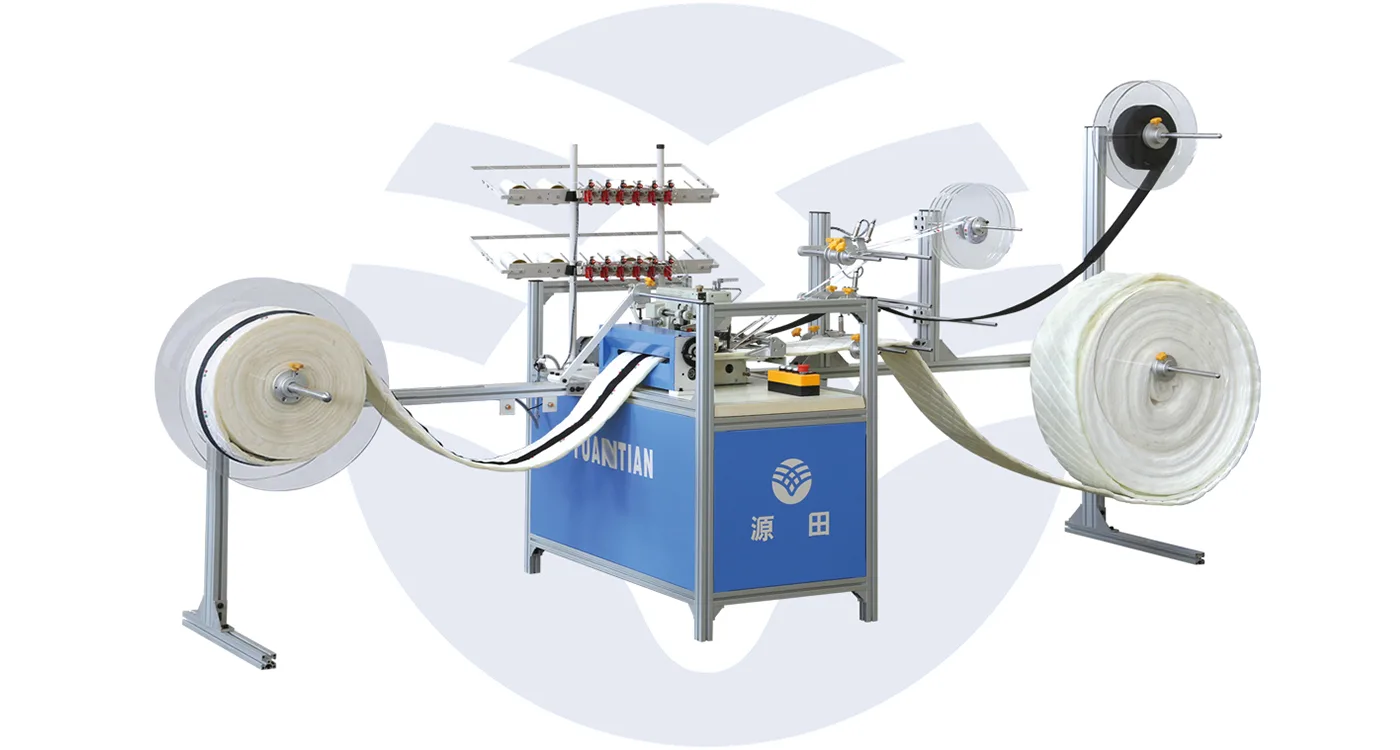

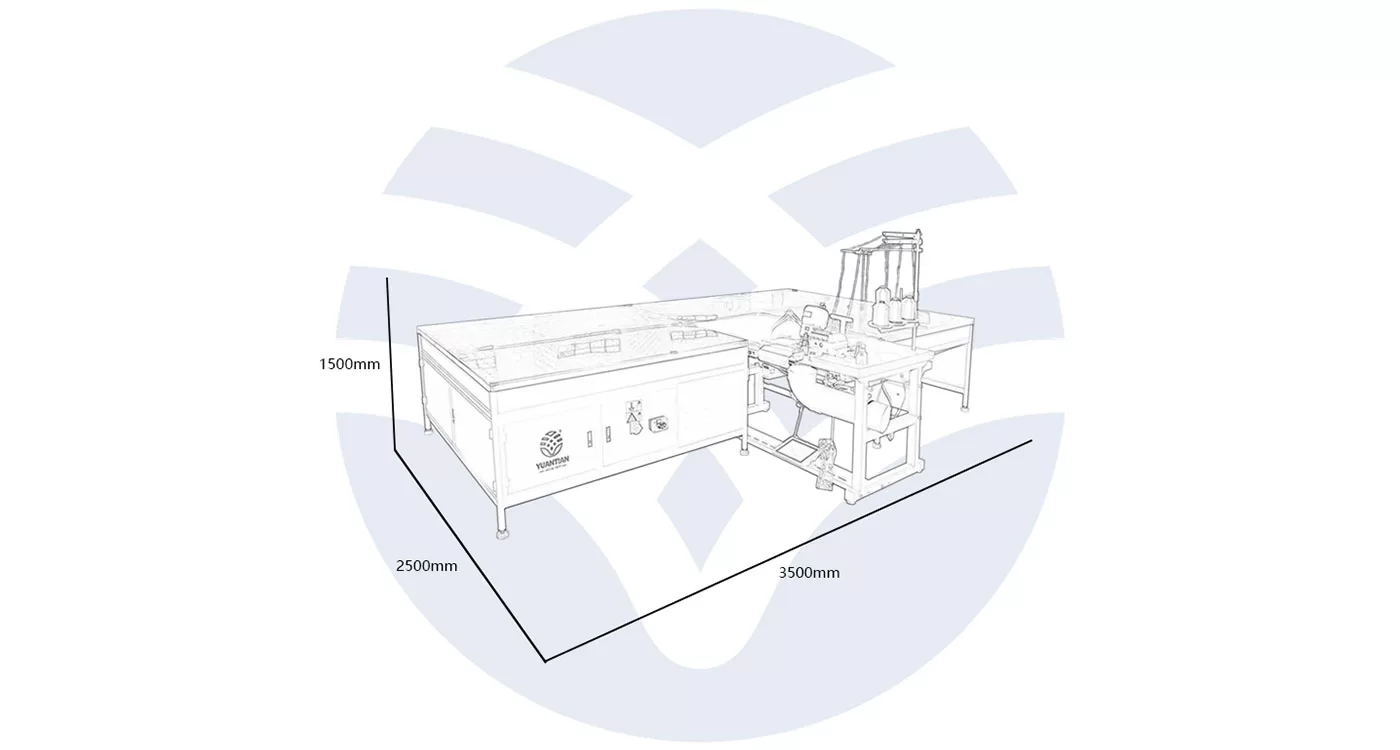

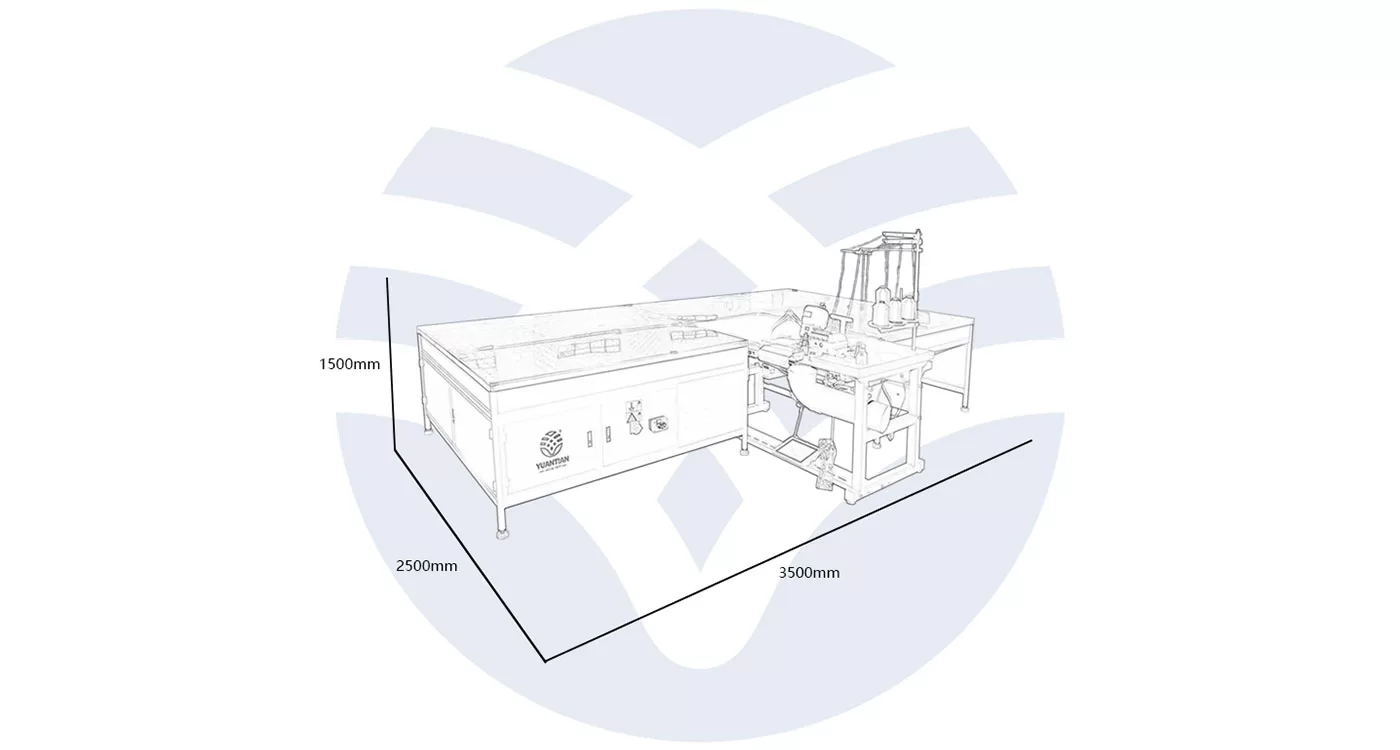

Flanging Machine+Air Blowing Table YT-DS-8B+YT-KQT-4

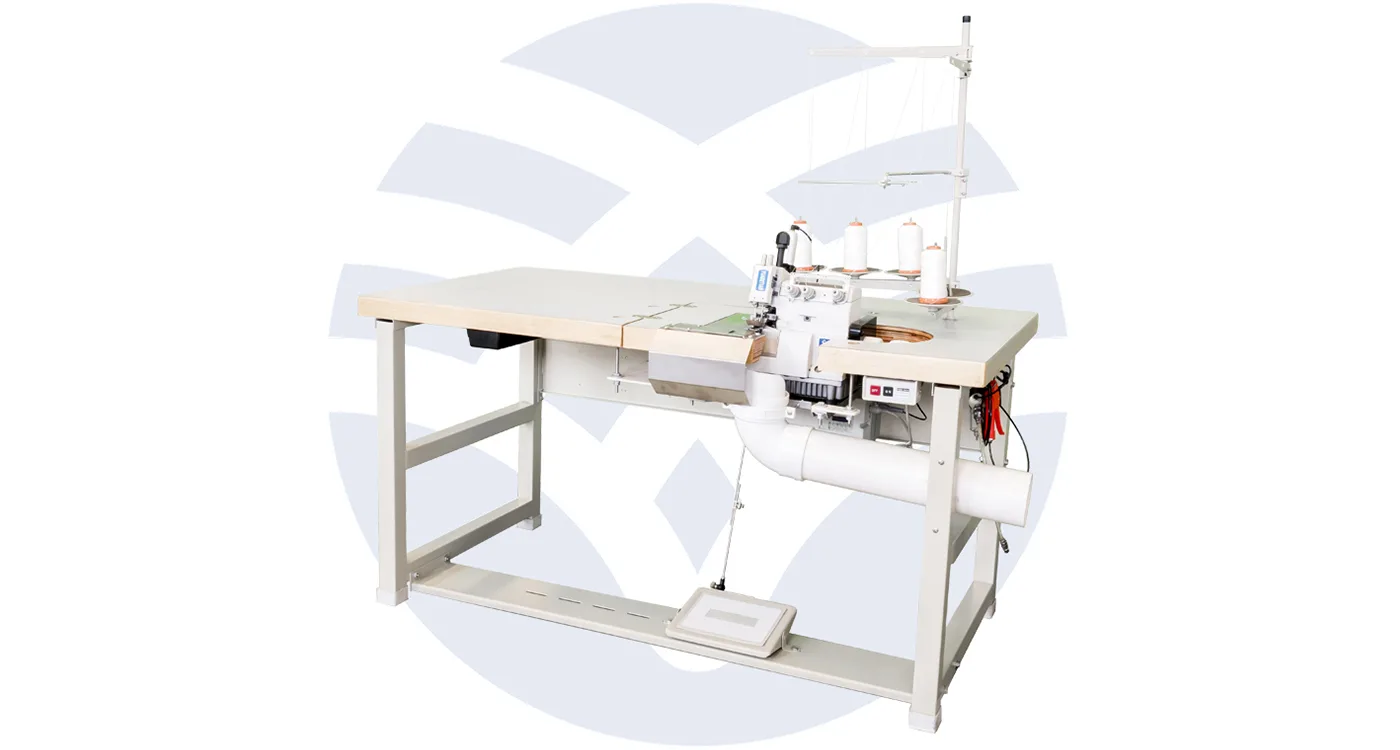

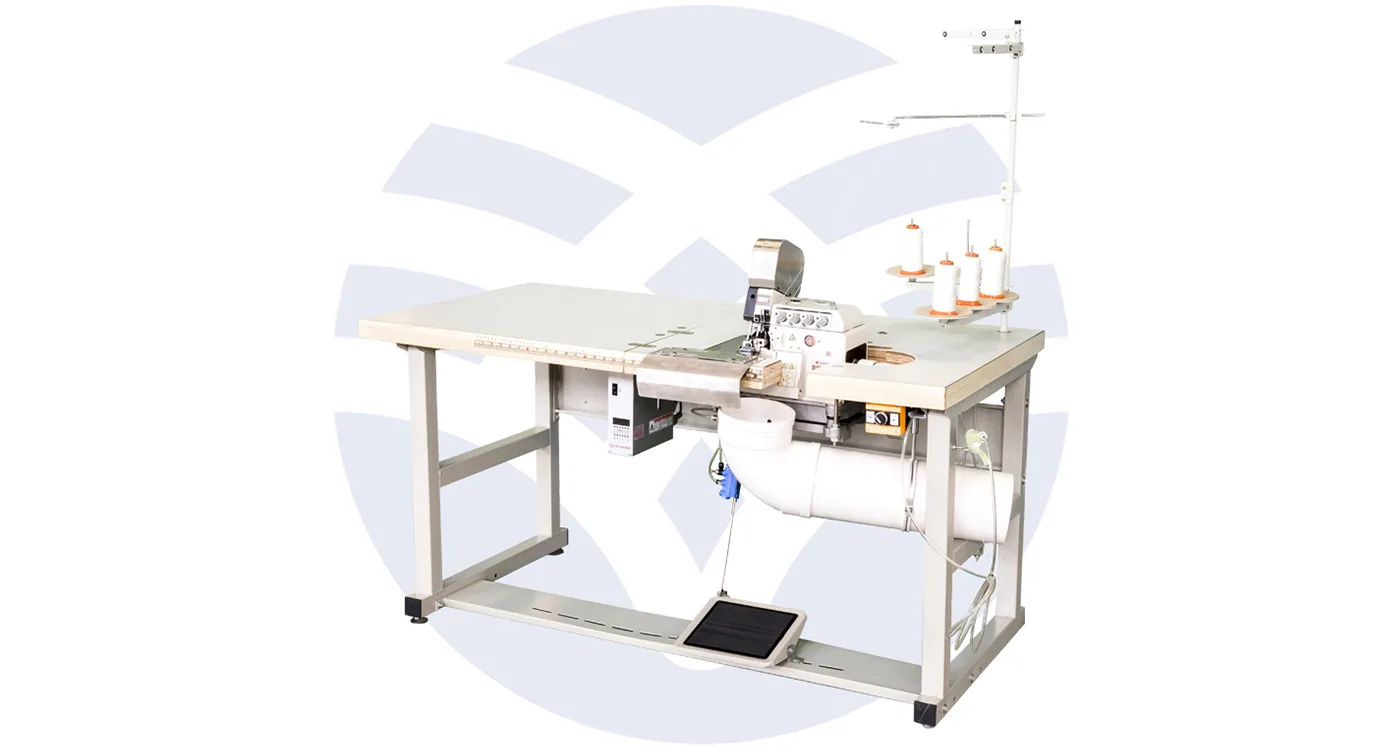

The YT-DS-8B Flanging Machine combined with the YT-KQT-4 Air Blowing Table is specially designed for efficient fabric processing, integrating core functions such as synchronous conveying, intelligent speed control, and flexible adjustment to provide a stable and reliable solution for edge flanging operations. The built-in synchronous conveying device uses precise mechanical and airflow control to ensure smooth and stable fabric transportation without deviation, effectively preventing edge wrinkles or processing errors caused by uneven tension and laying a foundation for high-quality flanging.

The digital electronic speed control system enables intuitive parameter setting, allowing operators to monitor and adjust the machine’s speed in real time via a clear display to adapt to different fabric thicknesses and processing requirements, balancing efficiency and precision. The adjustable material width function allows flexible adaptation to actual production needs, enabling precise positioning and stable processing for both narrow edging strips and wide furniture fabrics. The independently controllable presser foot and needle position design, supported by high-precision mechanics, ensures accurate control over the flanging trajectory. Combined with low-vibration, low-noise operation, it significantly improves workplace comfort while maintaining consistent processing quality during long-term high-frequency use.

This combined equipment can either integrate with upstream and downstream machines to form an automated production line or operate independently for flanging and fabric finishing. With its intelligent design and reliable performance, it becomes an ideal choice for enhancing efficiency and quality in mattress, furniture, and other fabric processing industries.

1. Synchronized tug device for smooth fabric.

2. Digital electronic speed regulation.

3. Adjustable size of material.

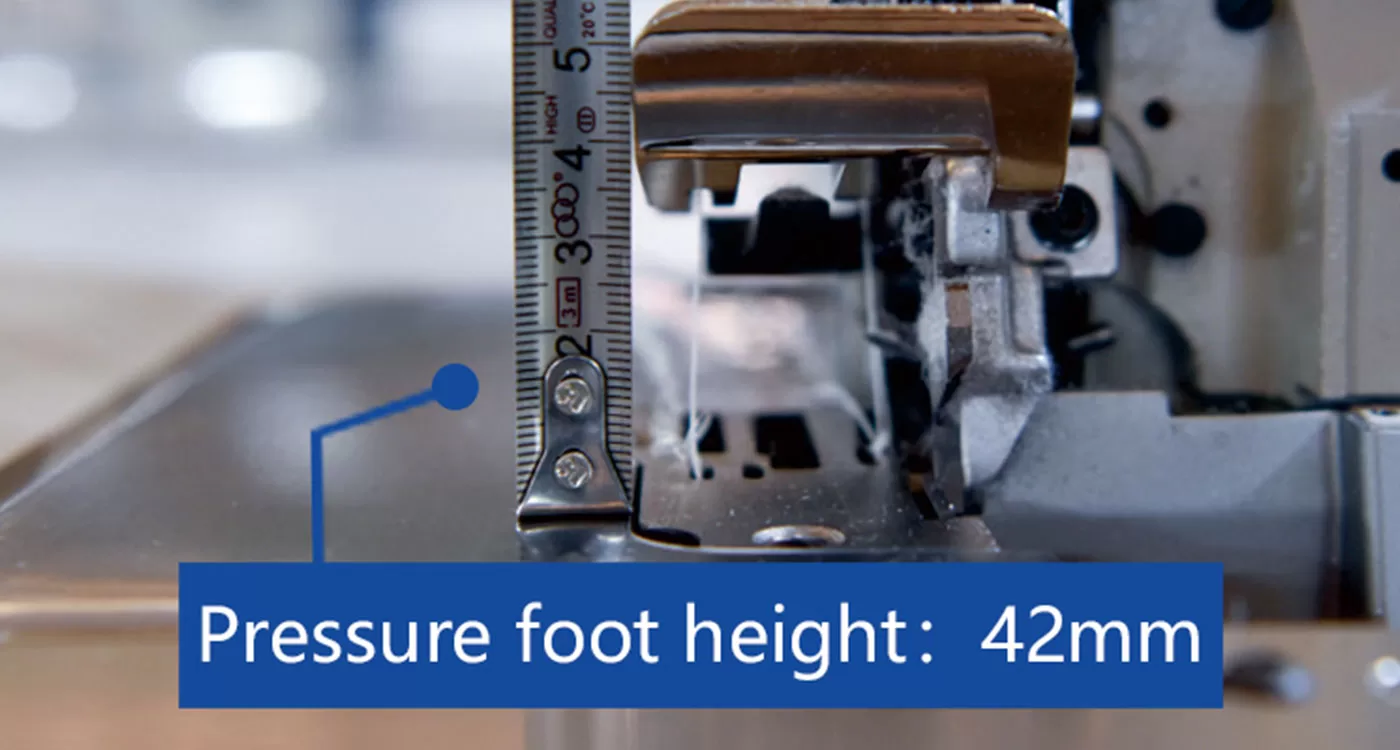

4. Presser foot and position needles can be controlled, low noise, stable performance.

| Flanging Width | 25mm | Lubrication | Shell C-10 Spindle Oil |

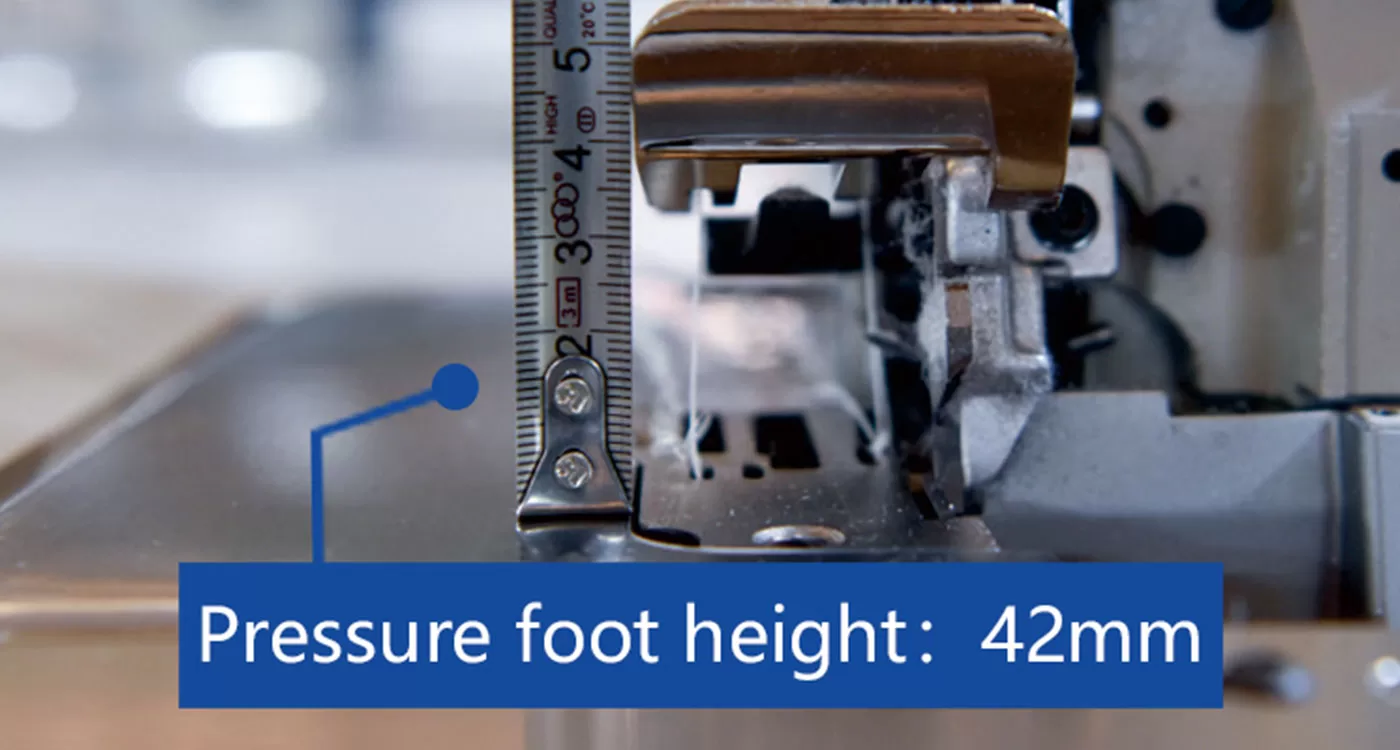

| Flanging Thickness | 10-100mm | Pressure Foot Height | 42mm |

| Stitch Length | 2-5.5mm | Total Power | 750W |

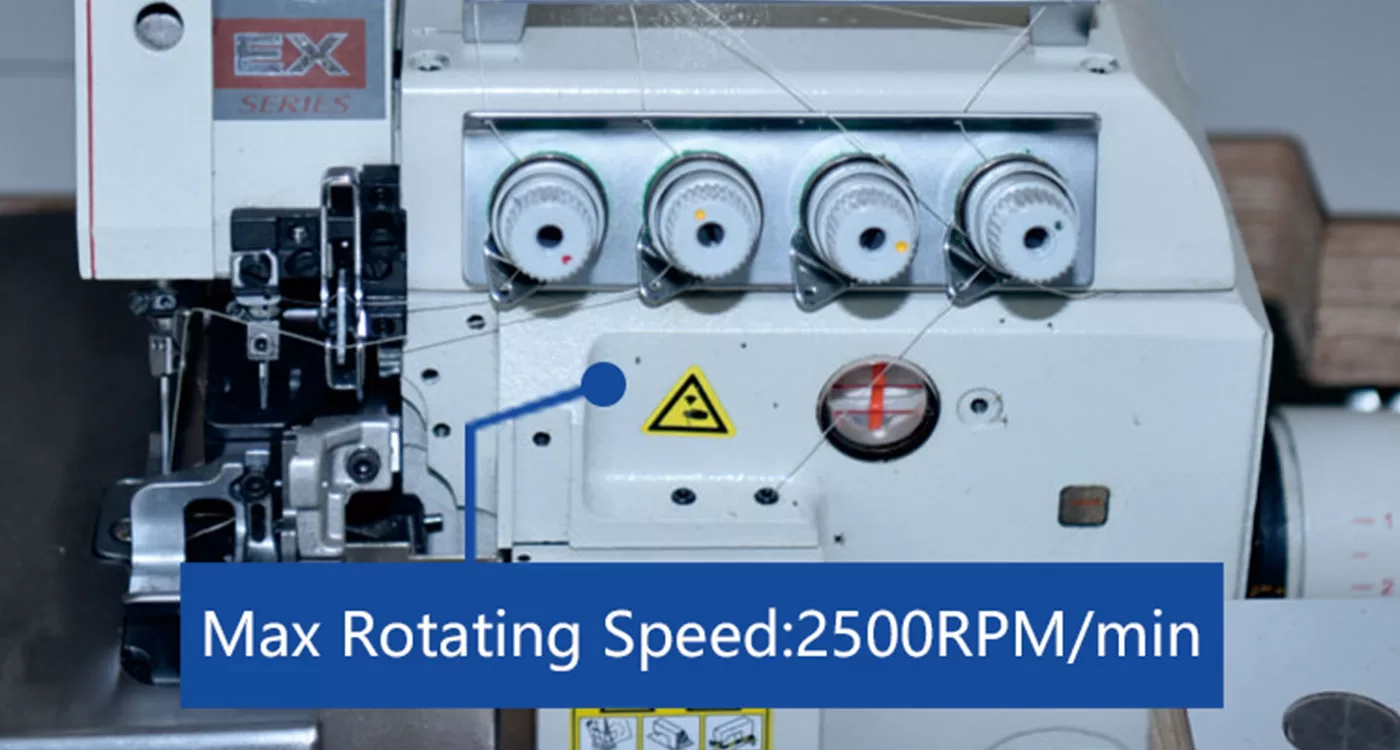

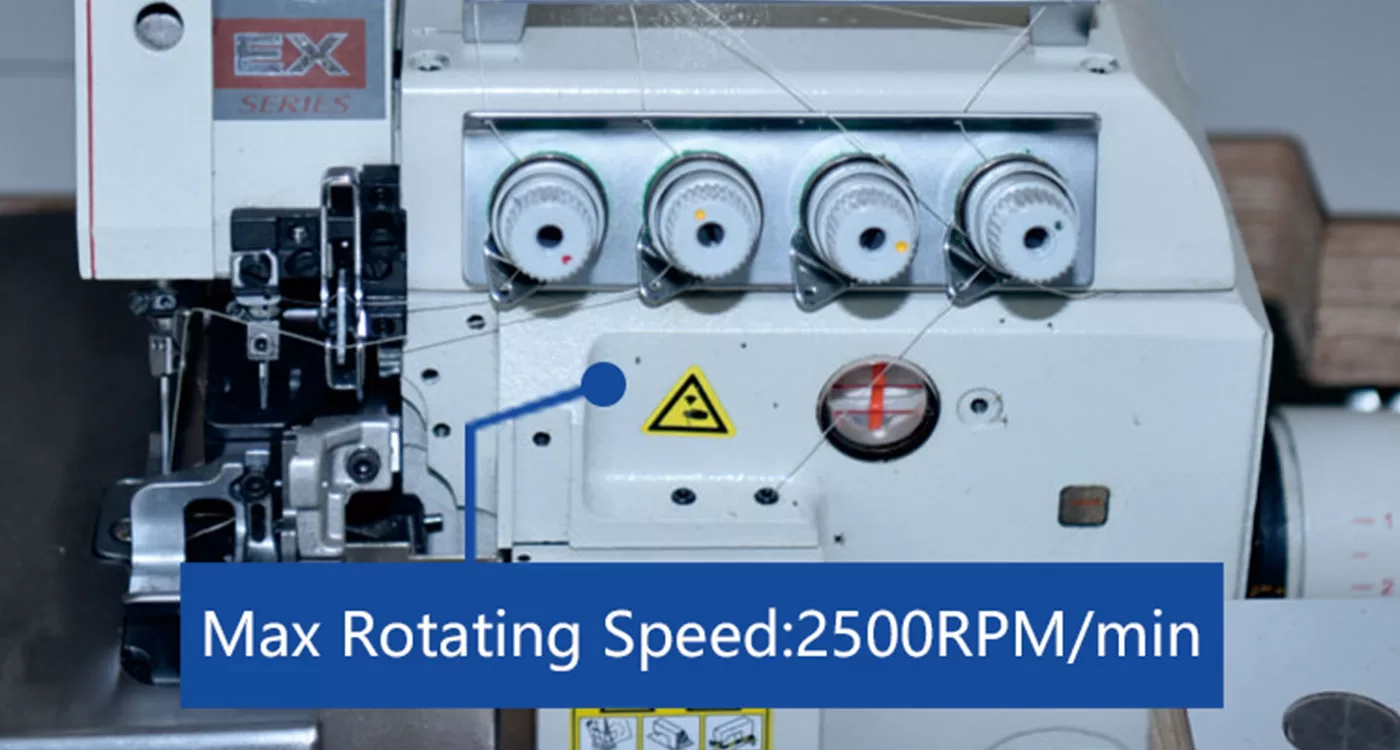

| Max Rotating Speed | 2500RPM/min | Power Supply | 220v50hz (Customizable as per customer requirements) |

| Needle | DPx5 22# | ||

| Needle Gauge | 20mm | Air Supply | 0.6-0.8Mpa |