- Home » MATTRESS MACHINERY » Mattress Quilting » Flanging Machine Series » Automatic Flanging Machine

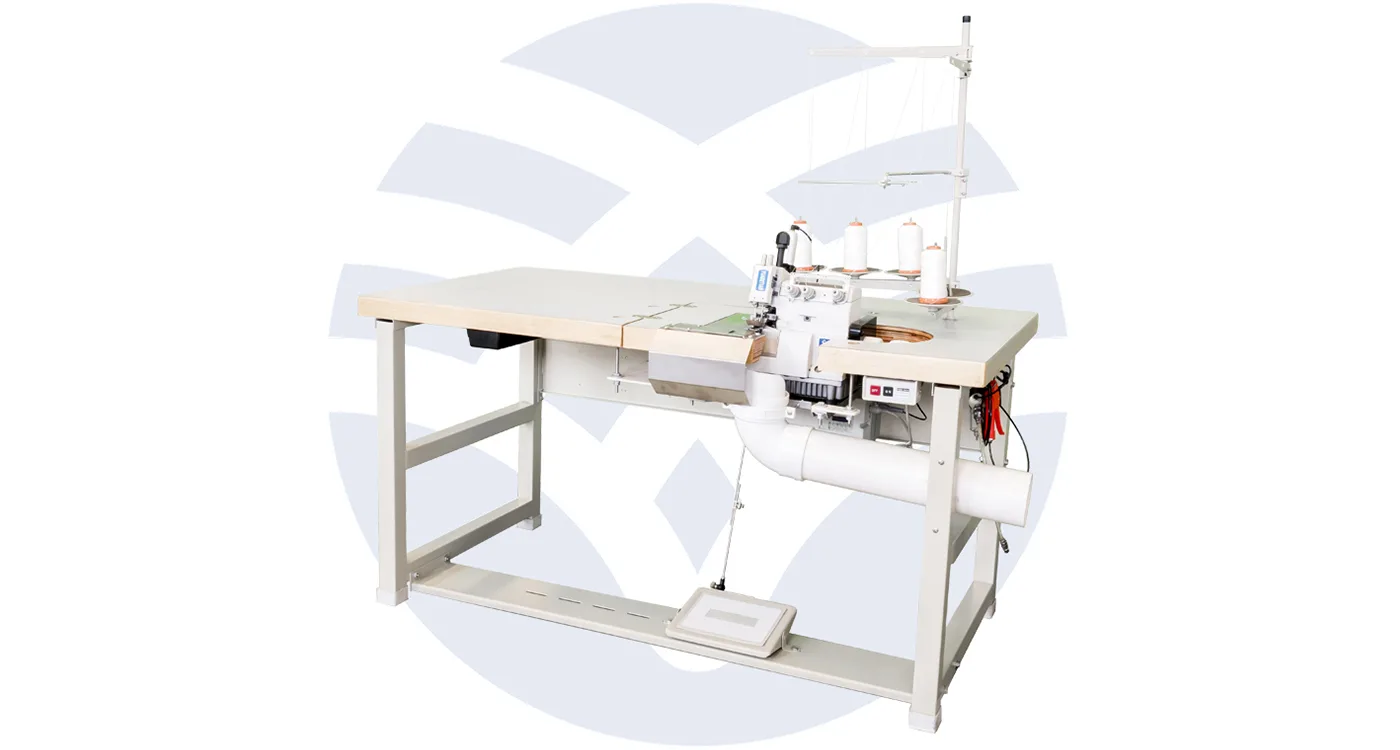

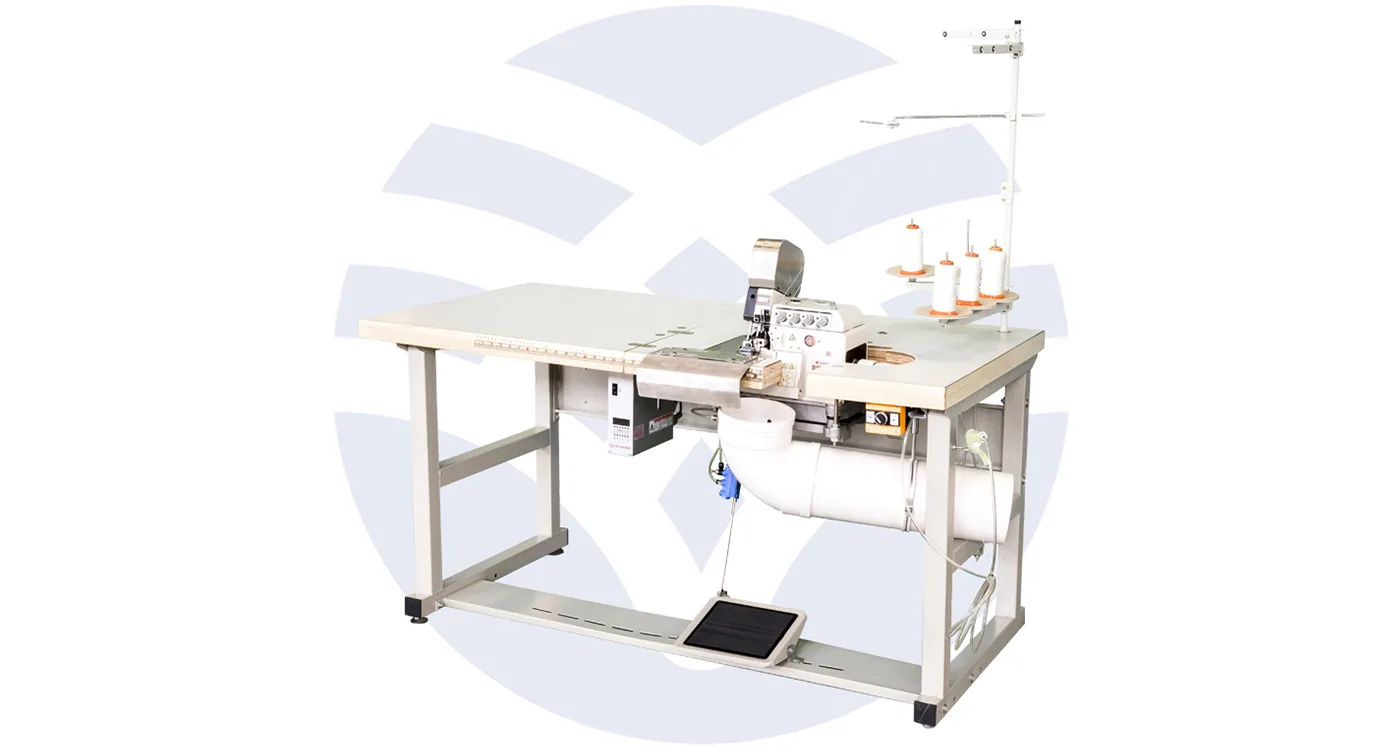

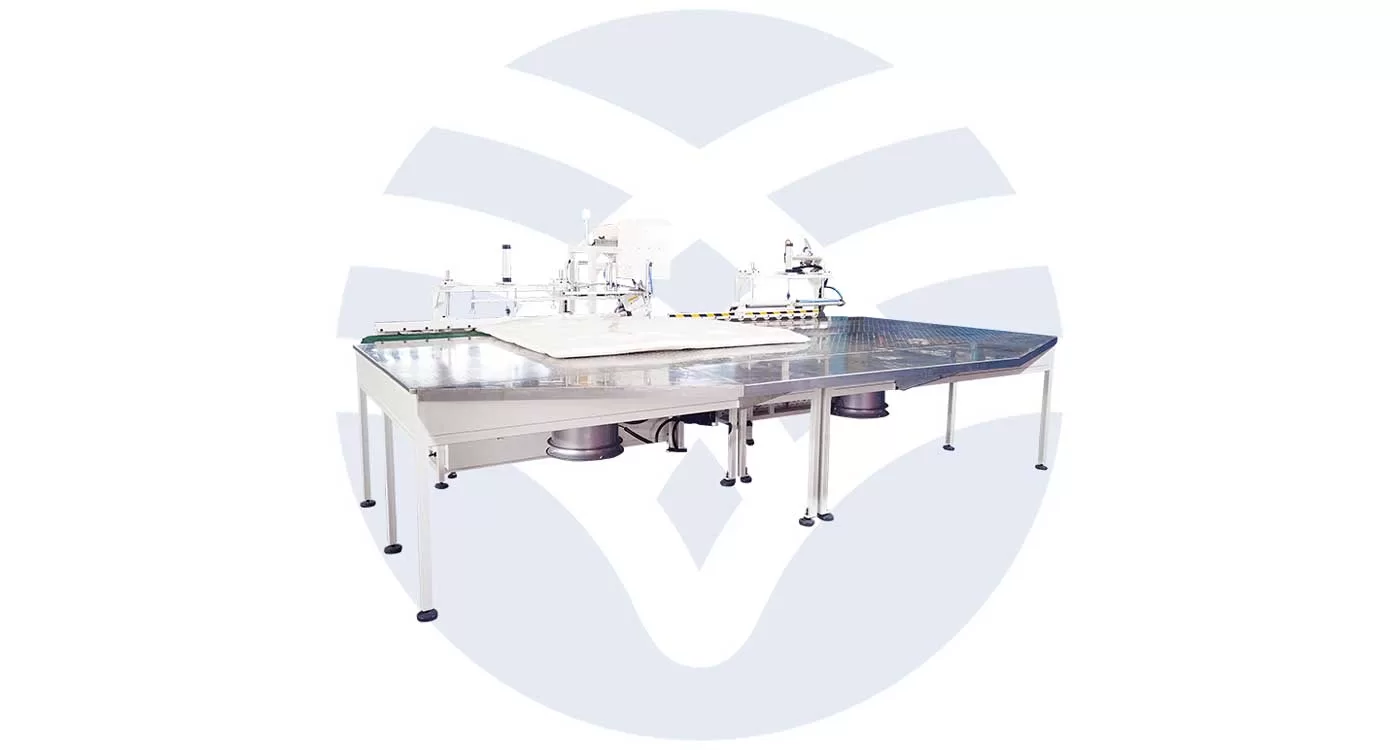

Automatic Flanging Machine YT-SB-9

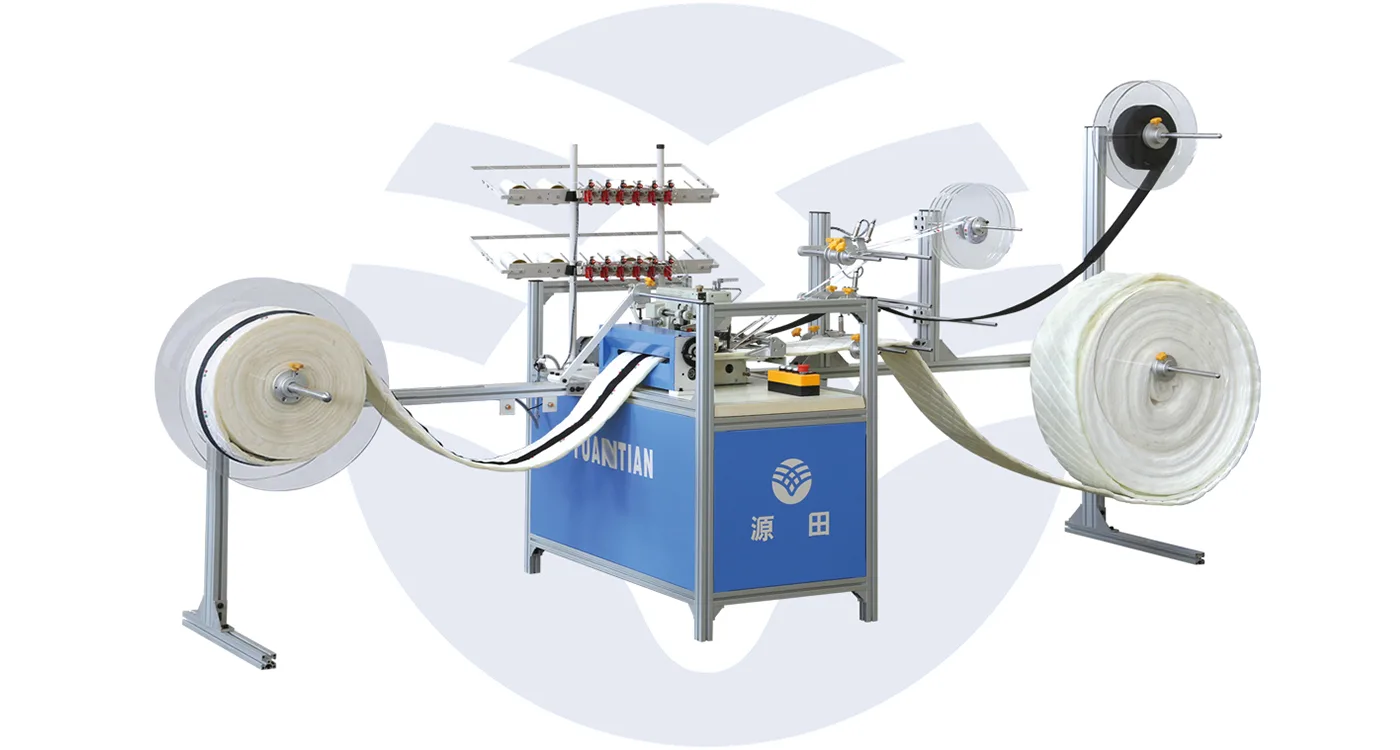

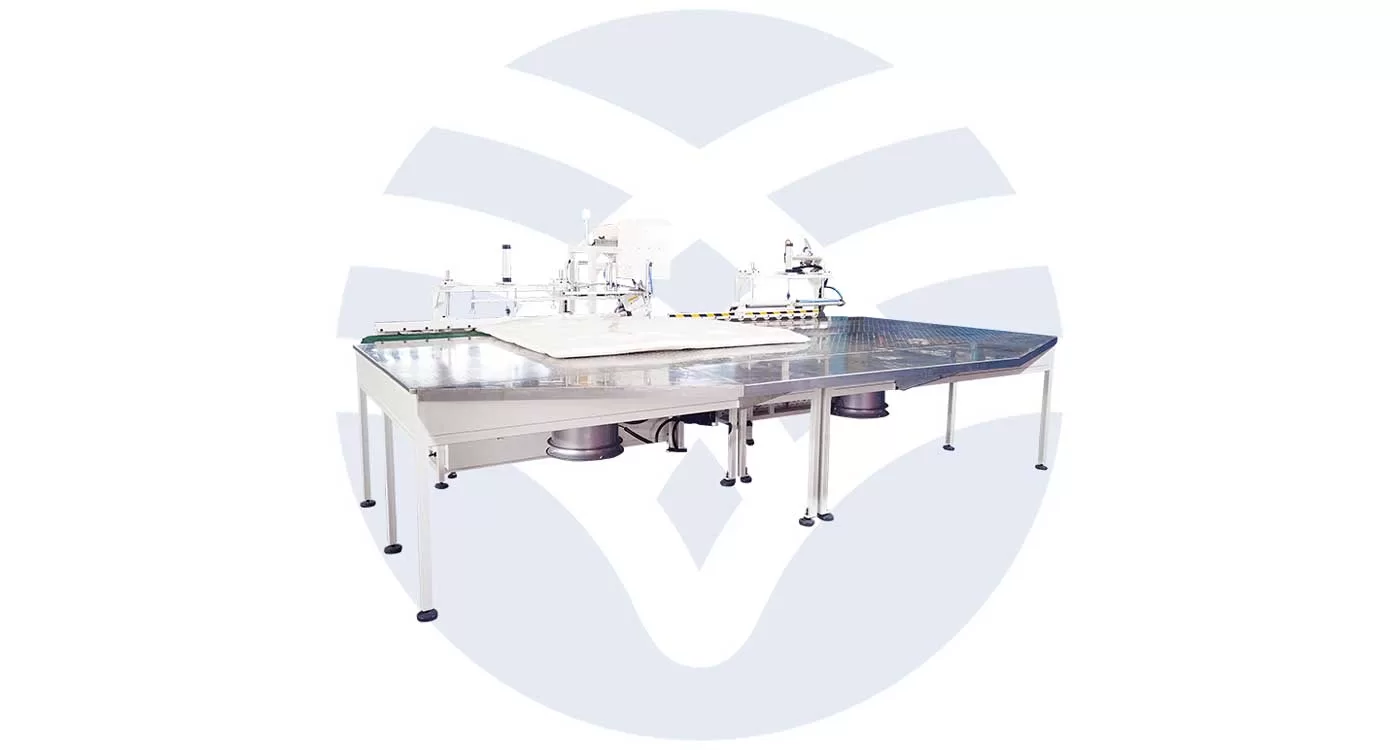

The YT-SB-9 Automatic Flanging Machine is designed for efficient fabric processing, optimizing the flanging workflow through automation to enhance production efficiency and processing quality. Its fully automatic flanging system enables continuous operation from fabric feeding to edge treatment, reducing manual intervention and effectively lowering operational intensity and labor costs.

The machine integrates intelligent detection and control functions: the automatic fabric length detection system uses sensors to capture dimensions in real time, minimizing the need for manual measurement and positioning while reducing potential human errors. The automatic feeding device employs synchronous drive technology to maintain good alignment of upper and lower fabric layers during transportation, decreasing the risk of displacement or wrinkling and providing a stable foundation for flanging. The fully computer-controlled HMI allows intuitive parameter adjustment via a touchscreen, enabling operators to easily set flanging width, stitch distance, speed, etc., to adapt to different fabric types with user-friendly operation.

The presser foot system combines pneumatic control and positioning sensors for automatic lifting and pressure adjustment, ensuring stable fabric alignment during processing while maintaining low noise levels. Suitable for both mass production of mattress/furniture fabrics and customized processing of clothing/home textiles, the YT-SB-9 offers reliable automation performance, convenient operation, and consistent edge treatment, making it a practical choice for optimizing production workflows in the fabric processing industry.

1. Fully automatic flanging work, improving work efficiency.

2. Automatically detects fabric length, no need for manual measurement and positioning, effectively reducing labor intensity.

3. Automatic feeding, accurate detection, ensuring synchronization of upper and lower fabric layers, avoiding displacement.

4. Human-machine interface, fully computer-controlled, easy to adjust, easy to operate.

5. Presser foot automatically lifts with pneumatically control, needle position controlled with precision sensor, stable operation with low noise.

YT-SB-9

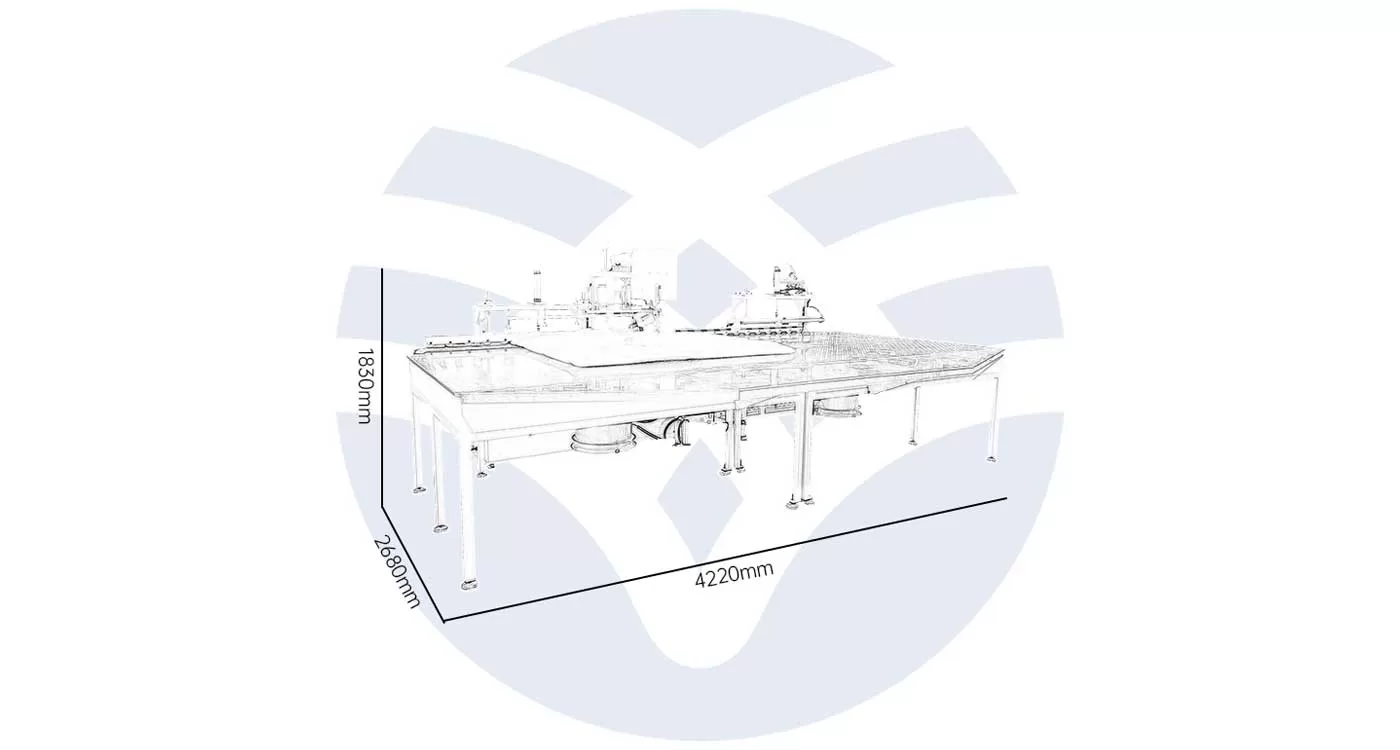

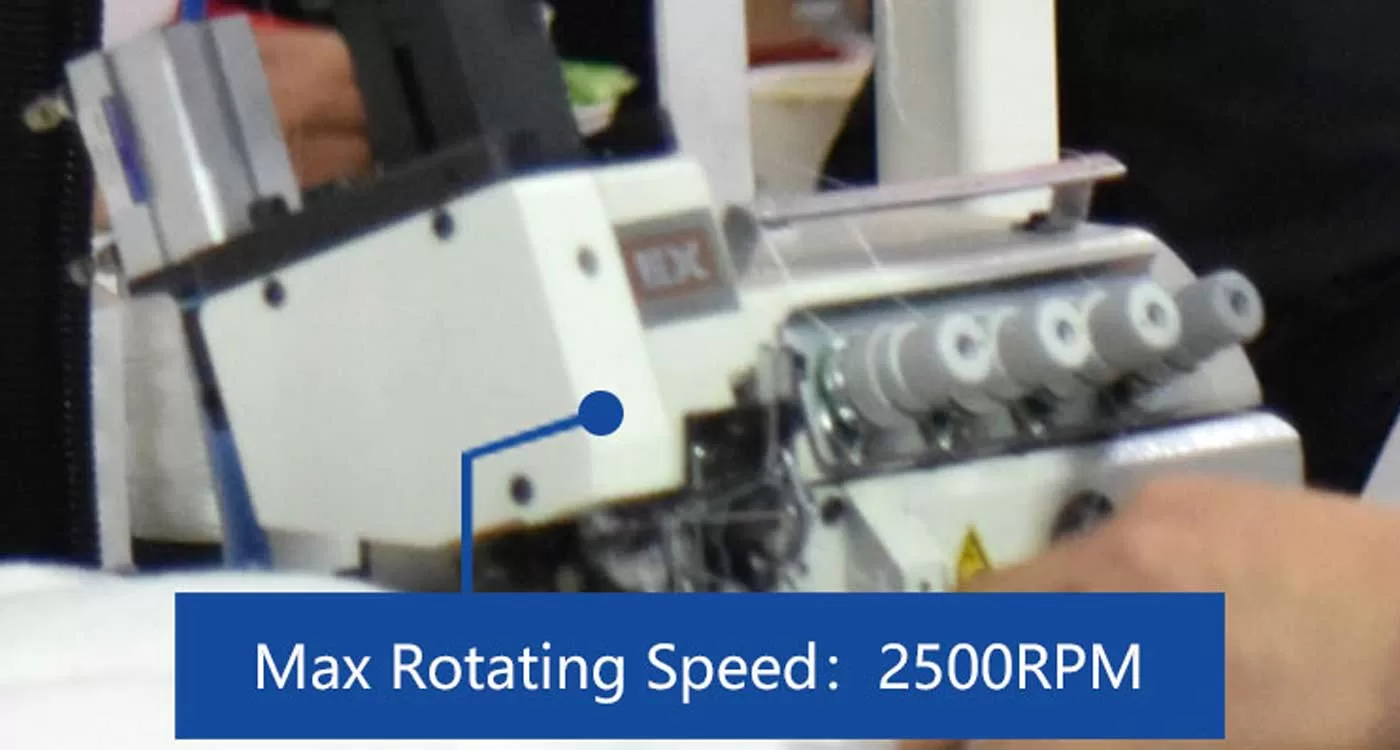

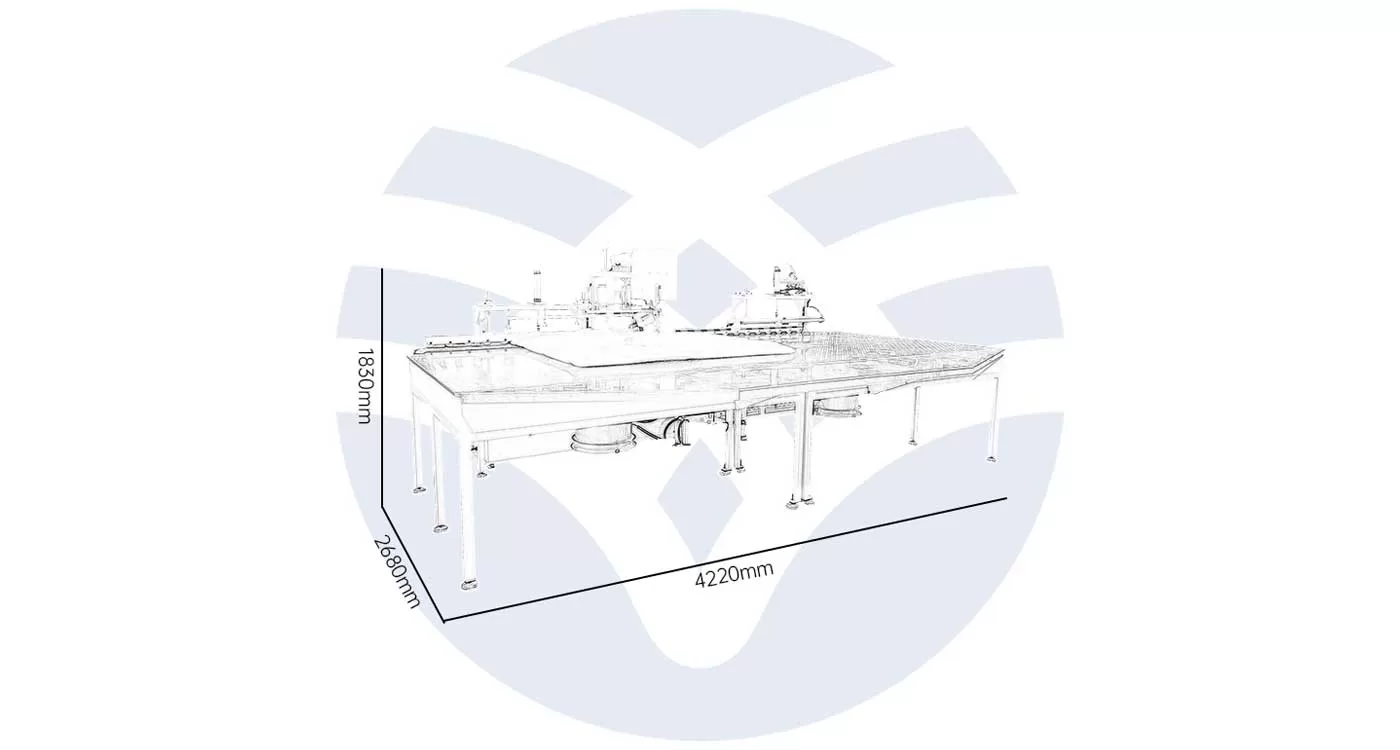

| Max Sewing Speed | 2500RPM | Overall Dimension | 4140×3260×1880mm |

| Flanging Thickness | 10-100mm | Total Power | 3kw |

| Flanging Width | 25mm (35mm enabled) | Power Supply | 3Ph380v50hz (Customizable as per customer requirements) |

| Stitch Pitch | 2-6mm | Air Supply | 0.6-0.8Mpa |

| Needle Gauge | 20mm (30mm enabled) | Total Weight | ≈1078KG |

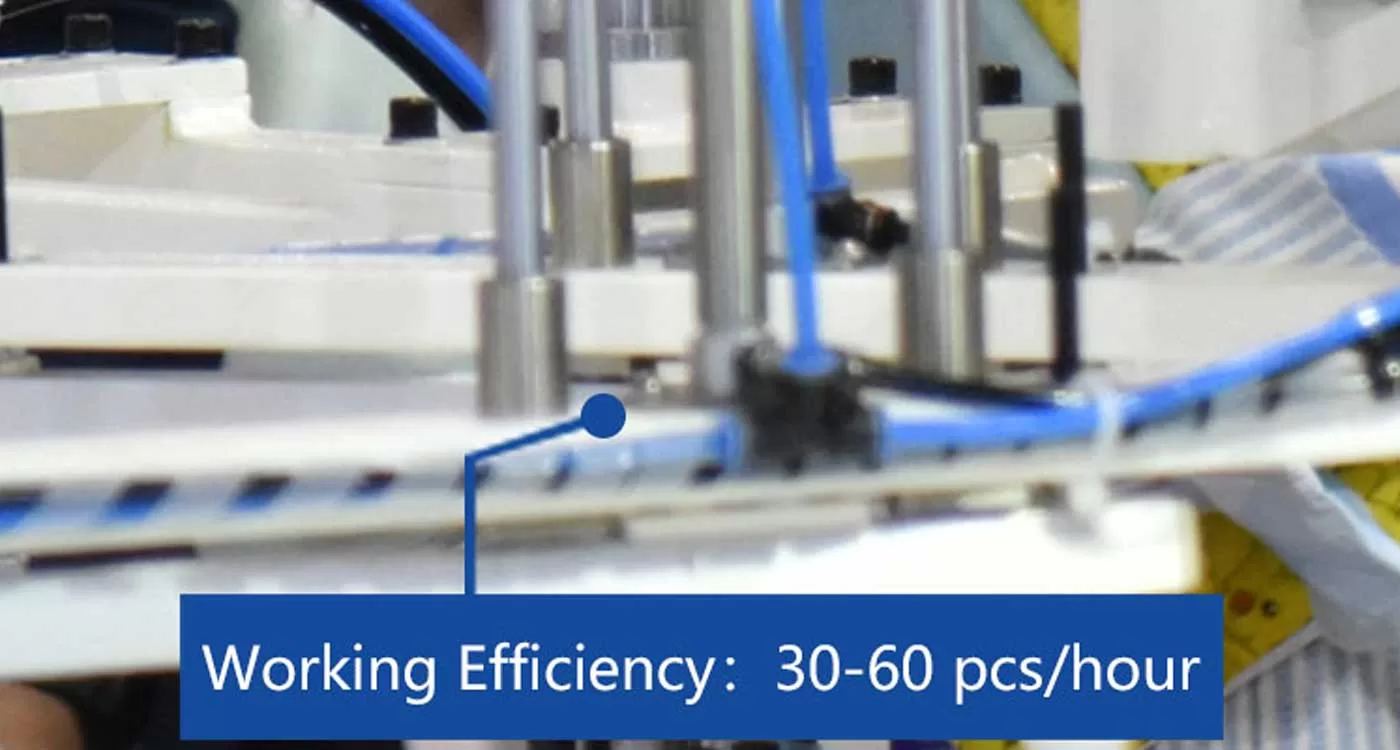

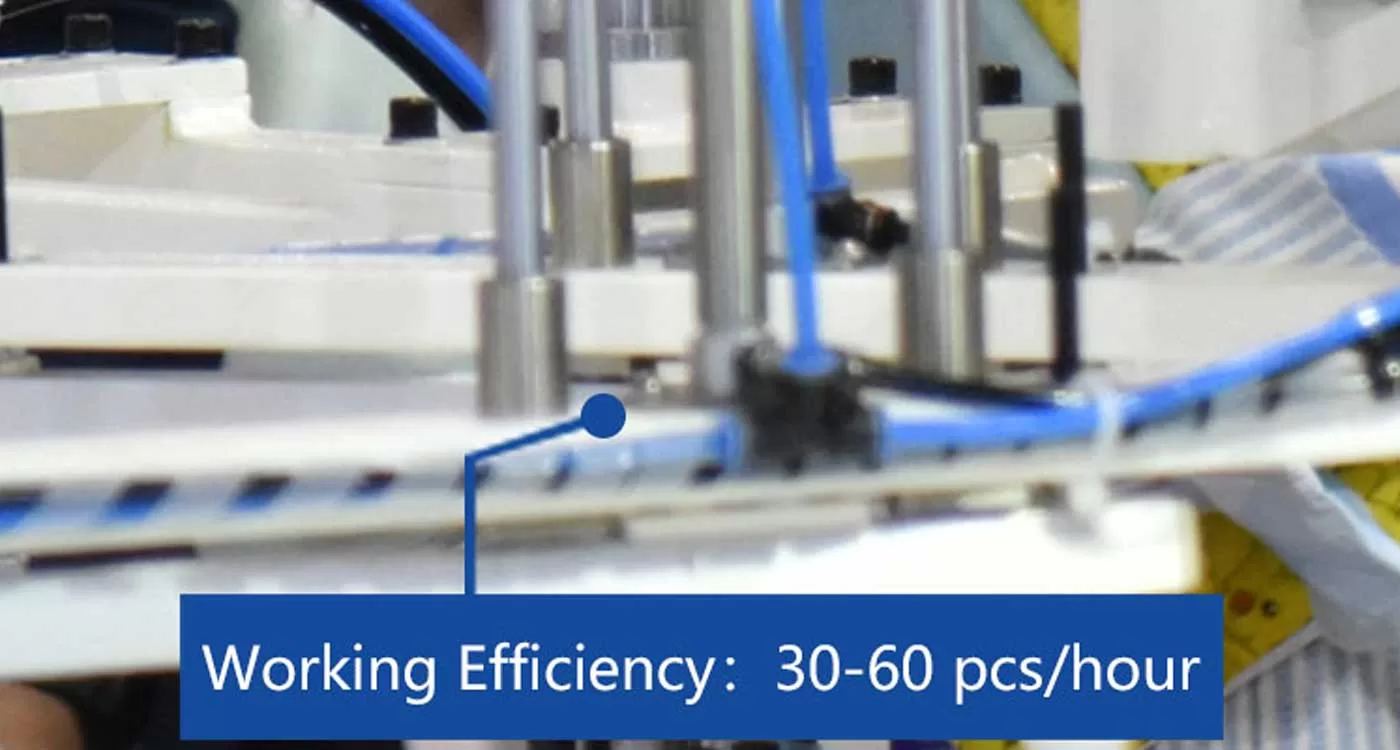

| Productivity | 30-60pcs/hour | Needle | PSM-1160#23 |