- Home » MATTRESS MACHINERY » Mattress Quilting » Flanging Machine Series » Cutting And Flanging Machine (Hemming System)

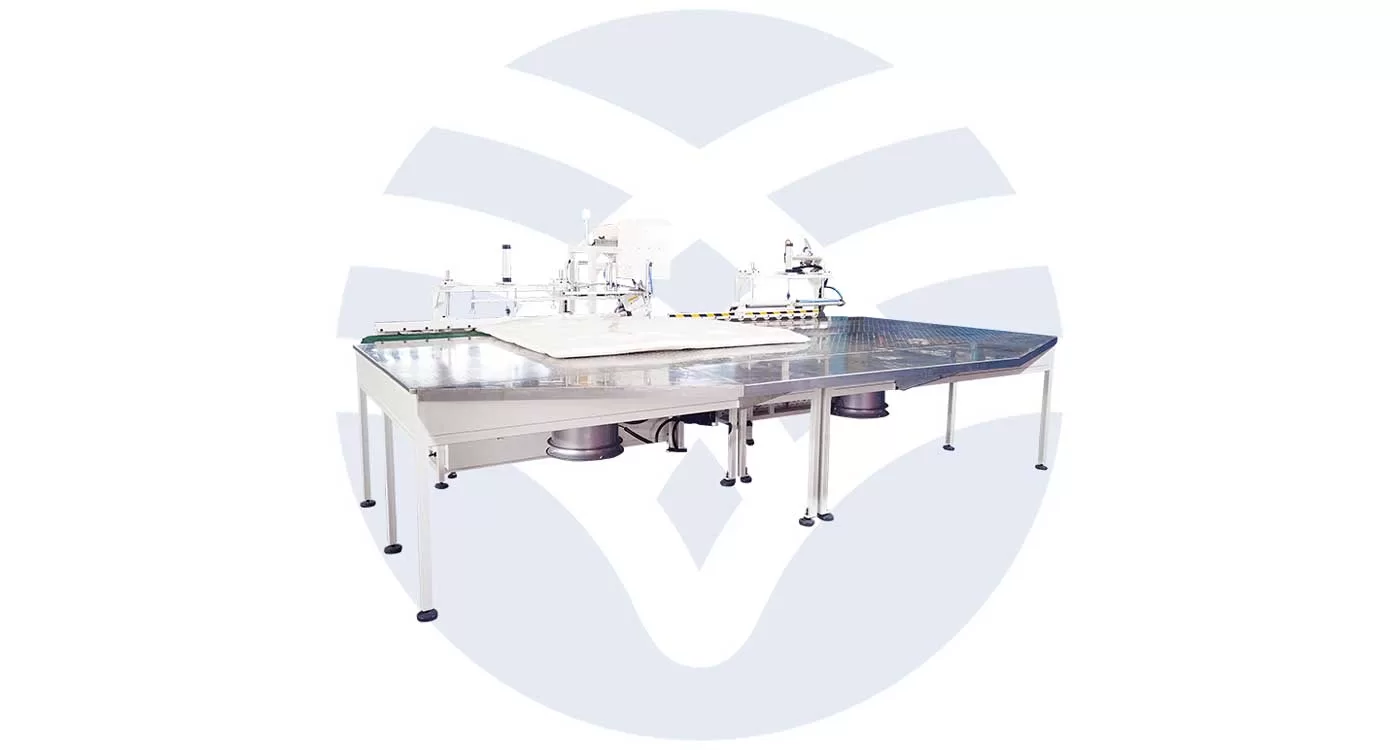

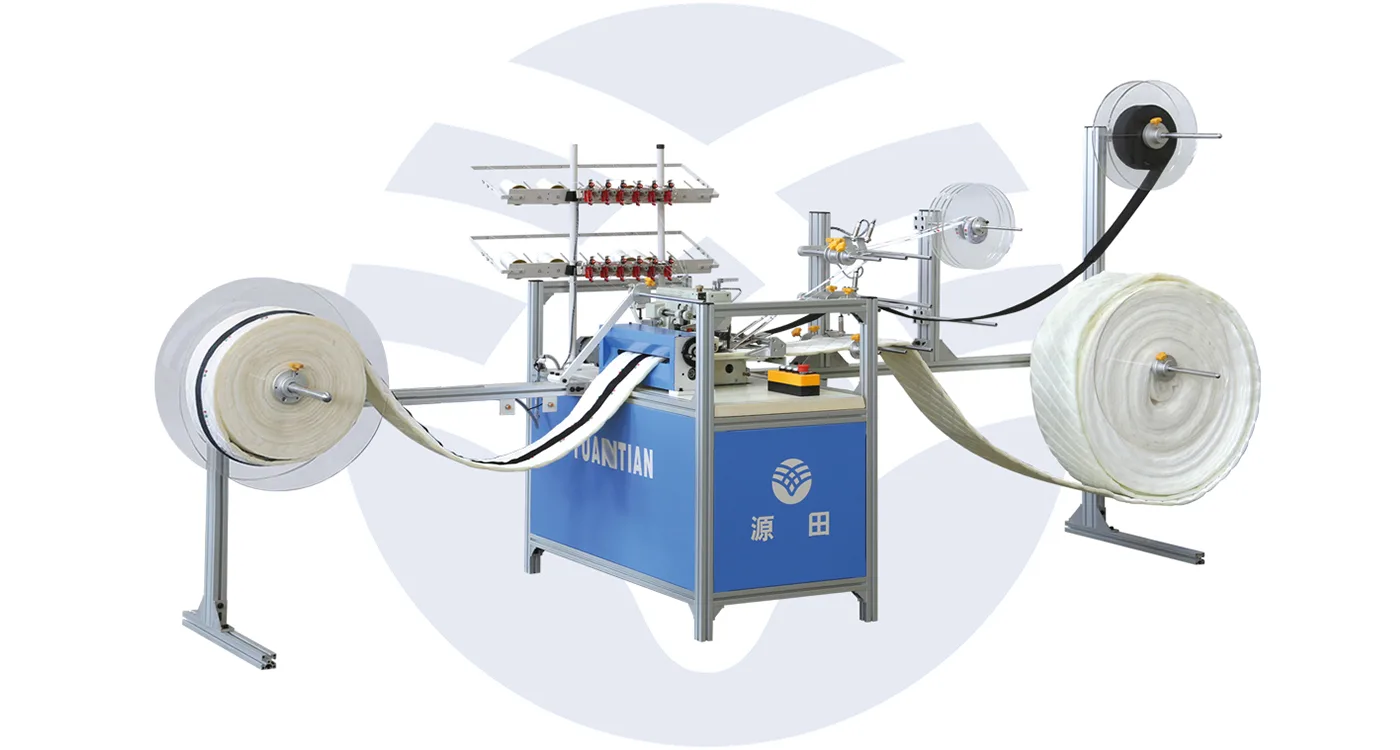

Cutting And Flanging Machine (Hemming System) YT-CS-4A

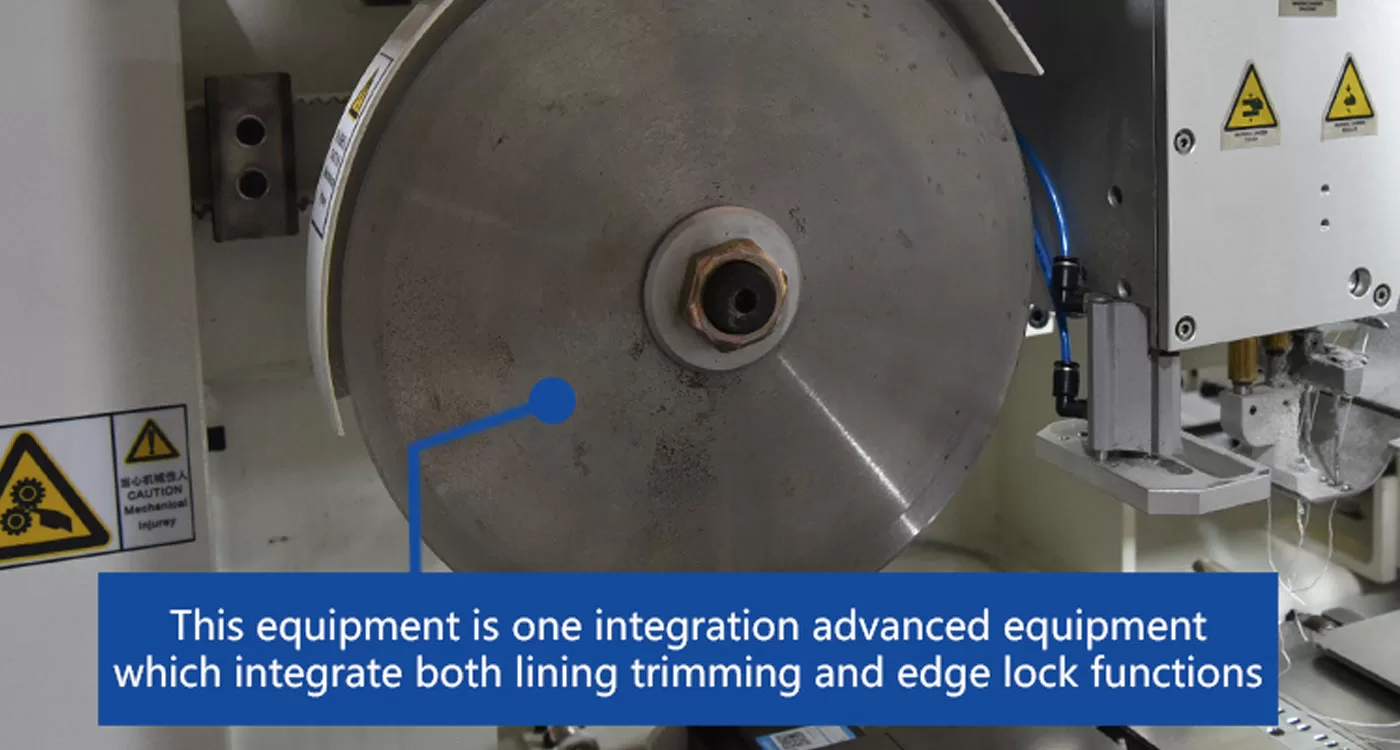

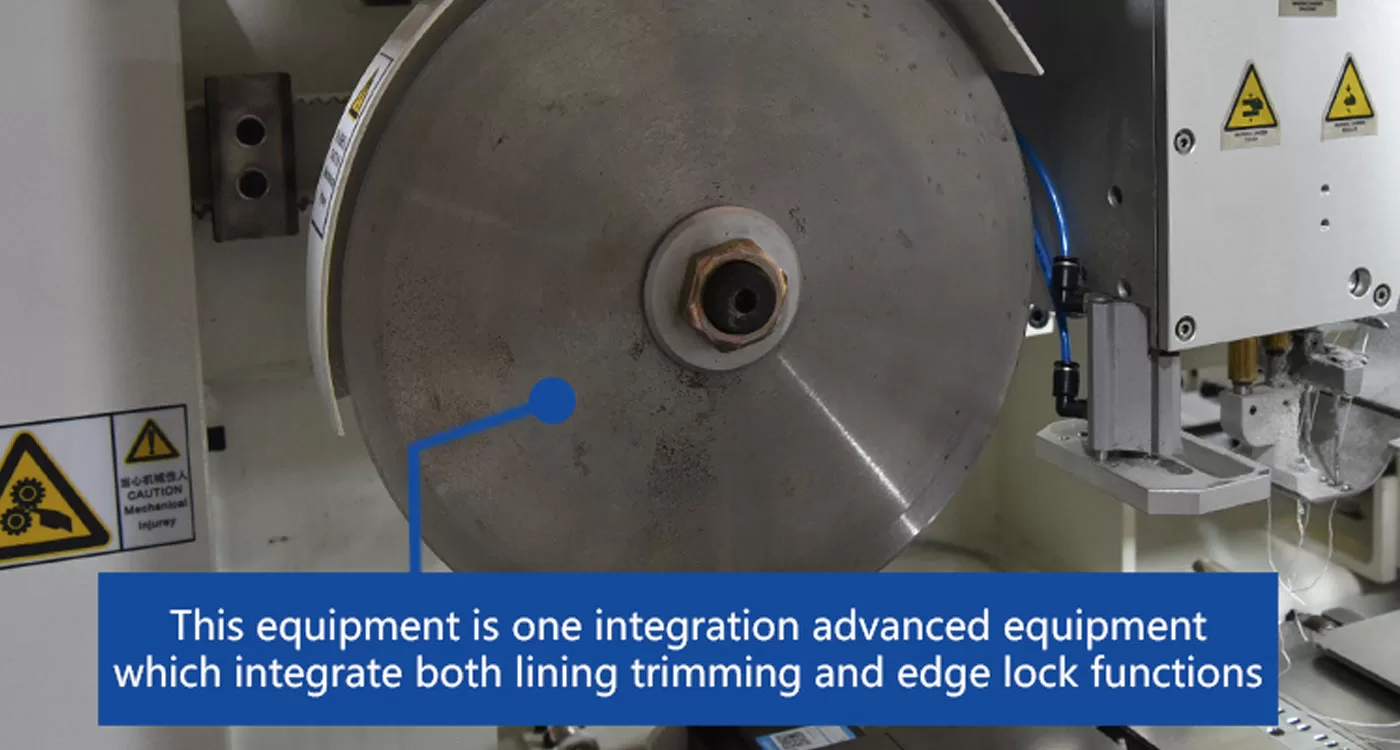

This advanced integrated equipment combines fabric cutting and edge locking functions, innovatively achieving simultaneous operation of cutting and edge locking to eliminate staged processing and significantly shorten production cycles. It can precisely cut various fabrics for mattresses and furniture, while efficiently locking the edges immediately after cutting to ensure neat and secure cuts, effectively preventing fraying or wear and providing high-quality semi-finished products for subsequent processes.

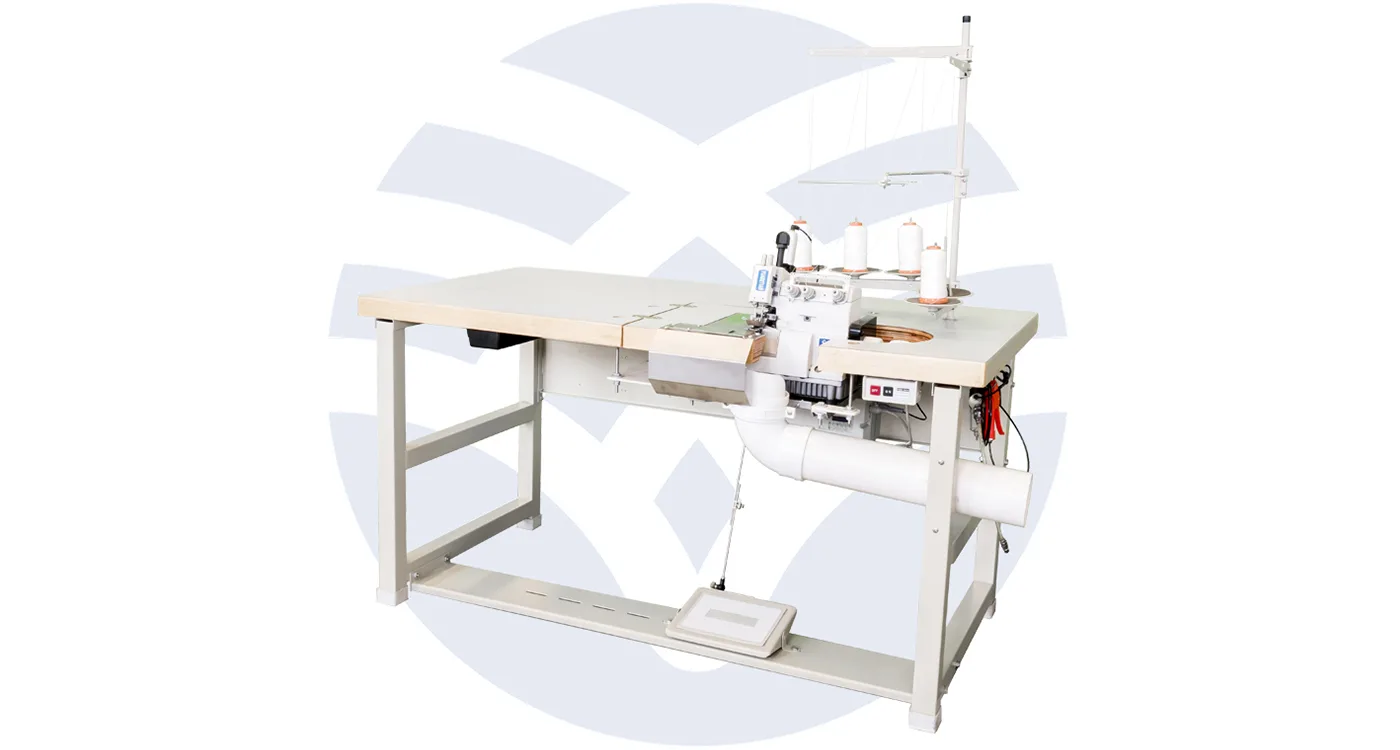

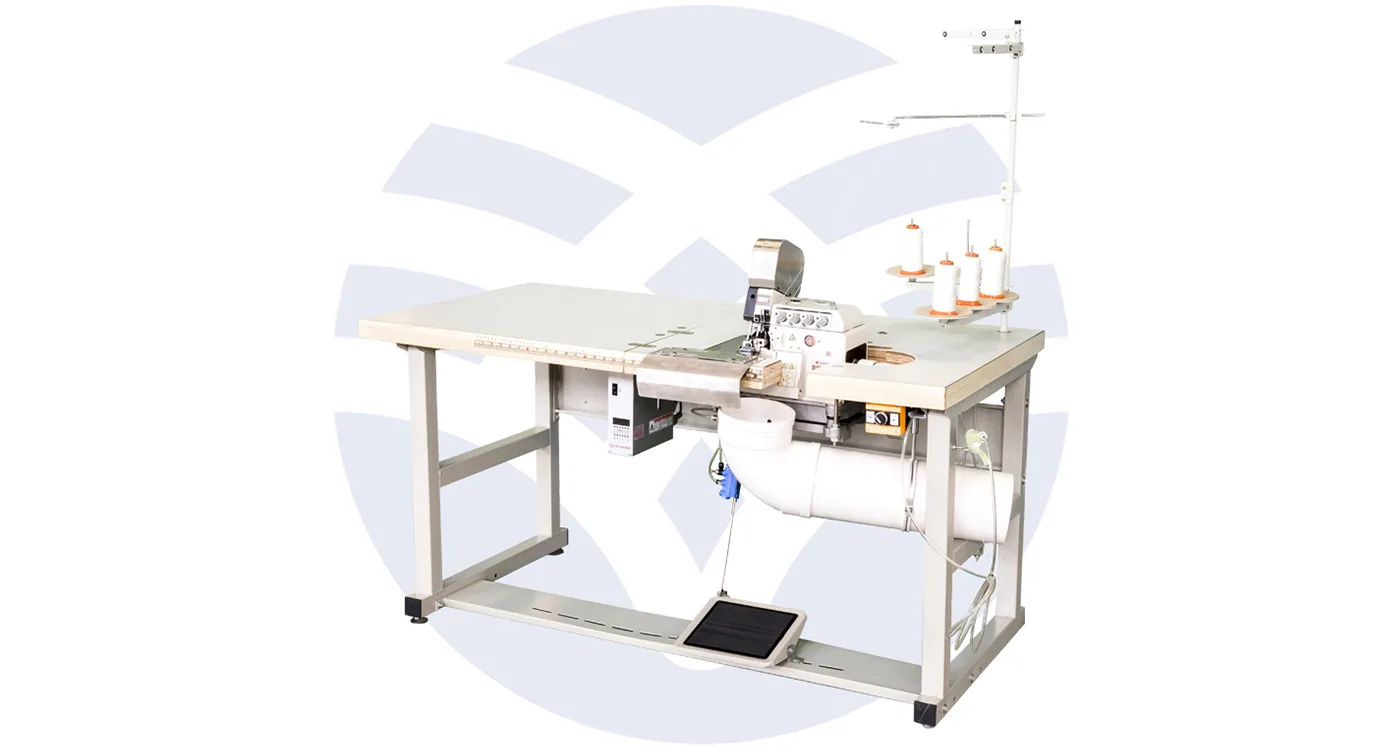

The machine offers flexible operation modes, capable of integrating with quilting machines and other equipment to form an automated production line for seamless workflow from fabric quilting to cutting and edge locking, as well as operating independently for small-batch customized production. Its integrated design eliminates the manual transfer between cutting and edge locking in traditional processes, drastically reducing human intervention. One machine completes two processes, saving over 50% labor cost compared to traditional separate equipment while avoiding time loss and quality deviations caused by process separation.

With stable and efficient operation, the intelligent control system precisely matches cutting and edge-locking speeds to ensure synchronous coordination and maintain processing accuracy. Whether for standardized mass production or personalized flexible manufacturing, this equipment stands out as an ideal solution for the furniture industry to optimize production workflows, enhance competitiveness, and achieve significant cost savings through its process-integration advantages and reliable performance.

1. This equipment is an integrated advanced equipment that integrates both cutting and flanging functions. The finished edge lock is done at the same time as cutting, which is beautiful when sewn with the trademark, reduces losses, has high production efficiency, saves labor for enterprises, and reduces production costs.

| Max Sewing Thickness | ≤70mm | Total Power | 8.0KW |

| Sewing Thickness | ≤70mm | Rated Power | 5 KW |

| Sewing Width | 1800-2200mm | Air Pressure | 0.6-0.8Mpa |

| Needle Model | Dvx59 24 | Total Weight | ≈4000KG |

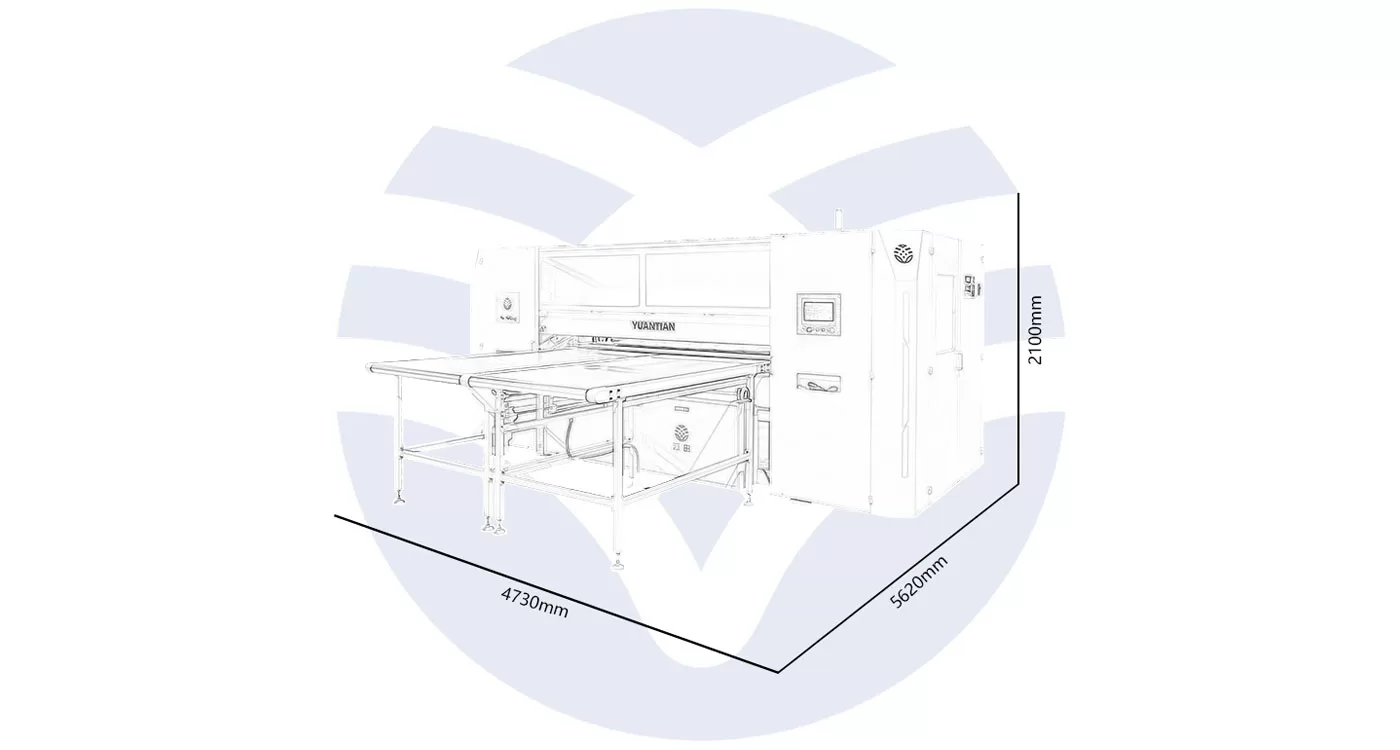

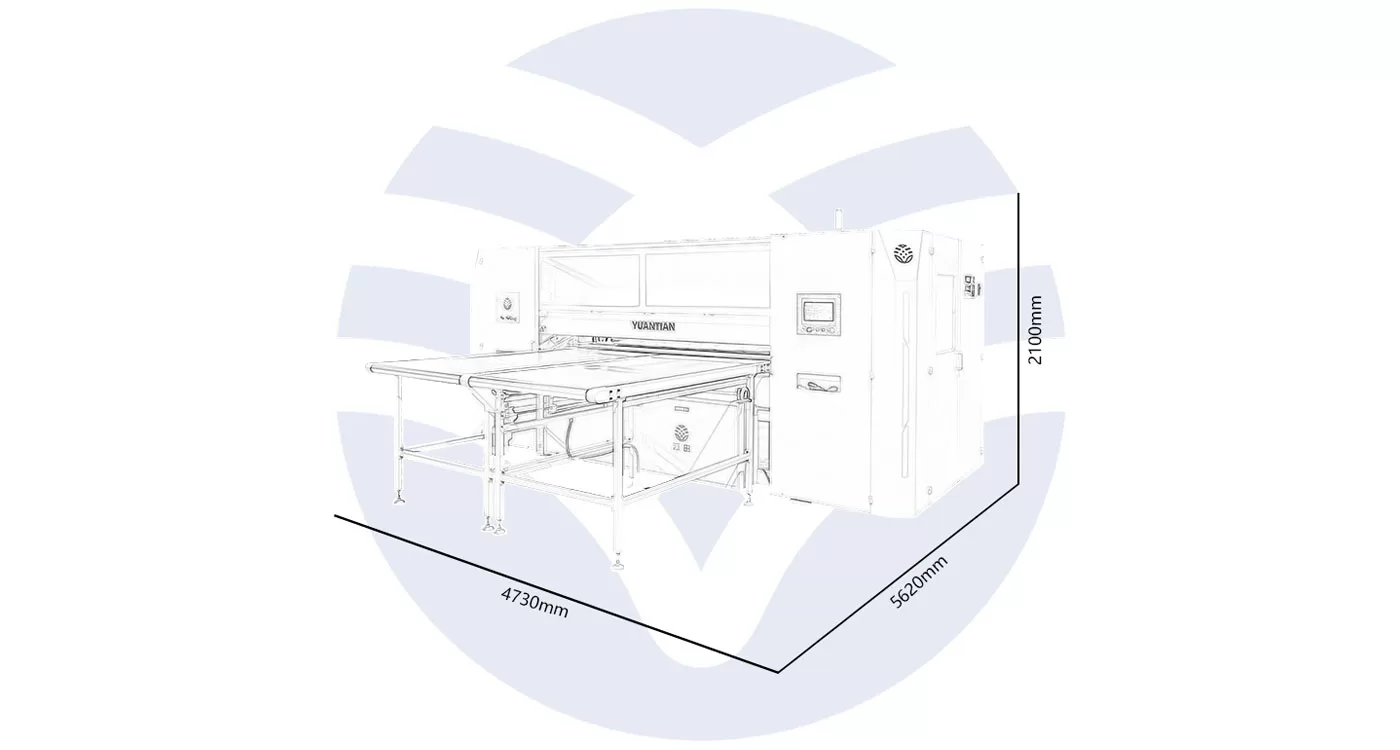

| Stitches Per Minute | ≤2500RPM | Overall Dimension | 5620*4730*2100mm |

| Stitch Length | 1-8mm | ||

| Sewing Speed | ≤15m/min | Power Supply | 3Ph380v50hz (Customizable as per customer requirements) |