- Home » MATTRESS MACHINERY » Mattress Tape Edging » Tape Edge Machine Series » Double Layer Automatic Tape Edge Machine

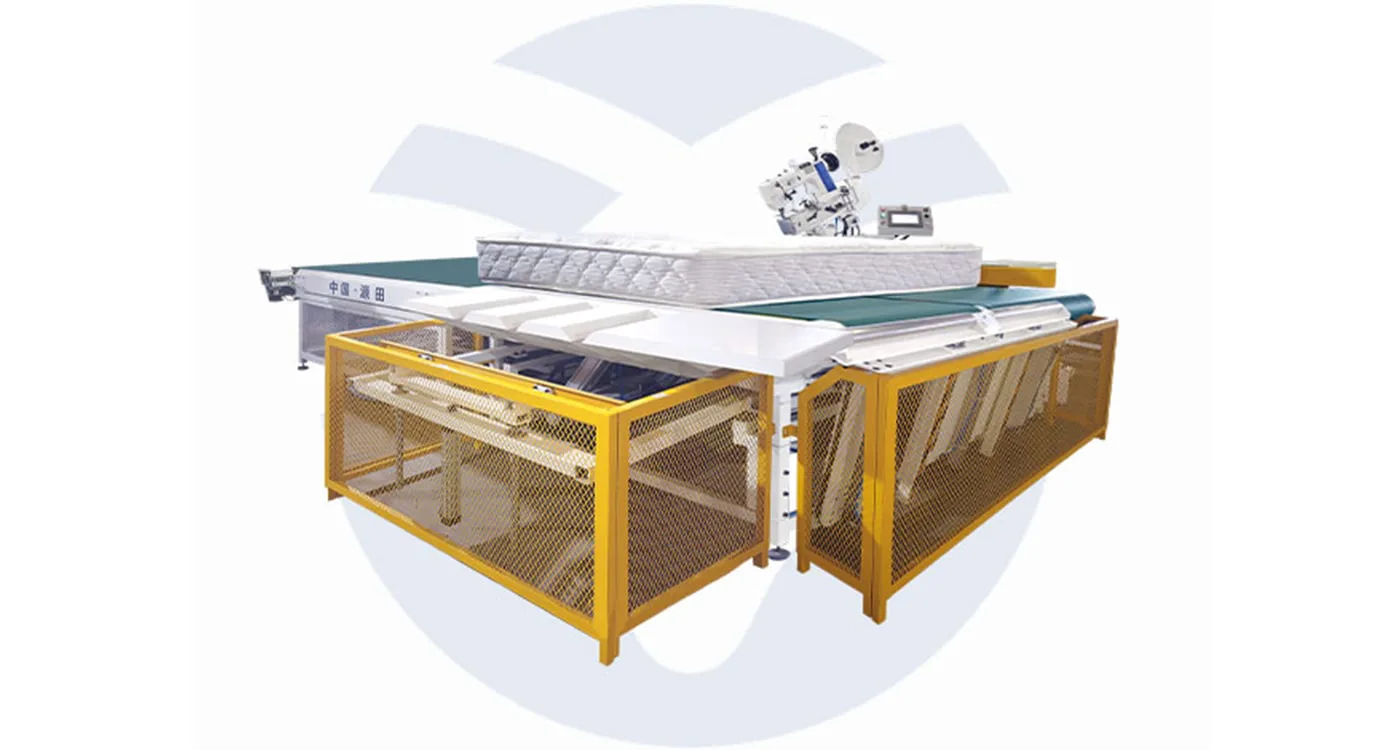

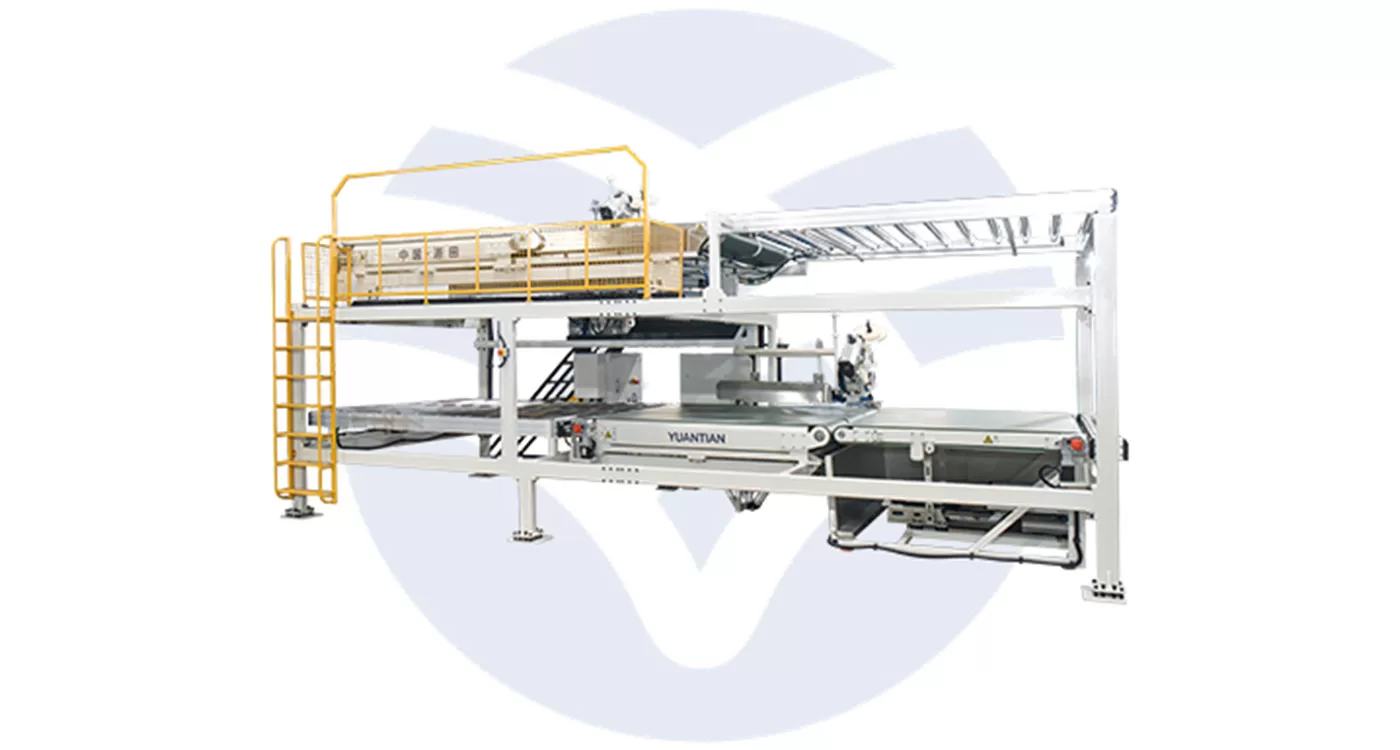

Double Layer Automatic Tape Edge Machine YT-WB-6A

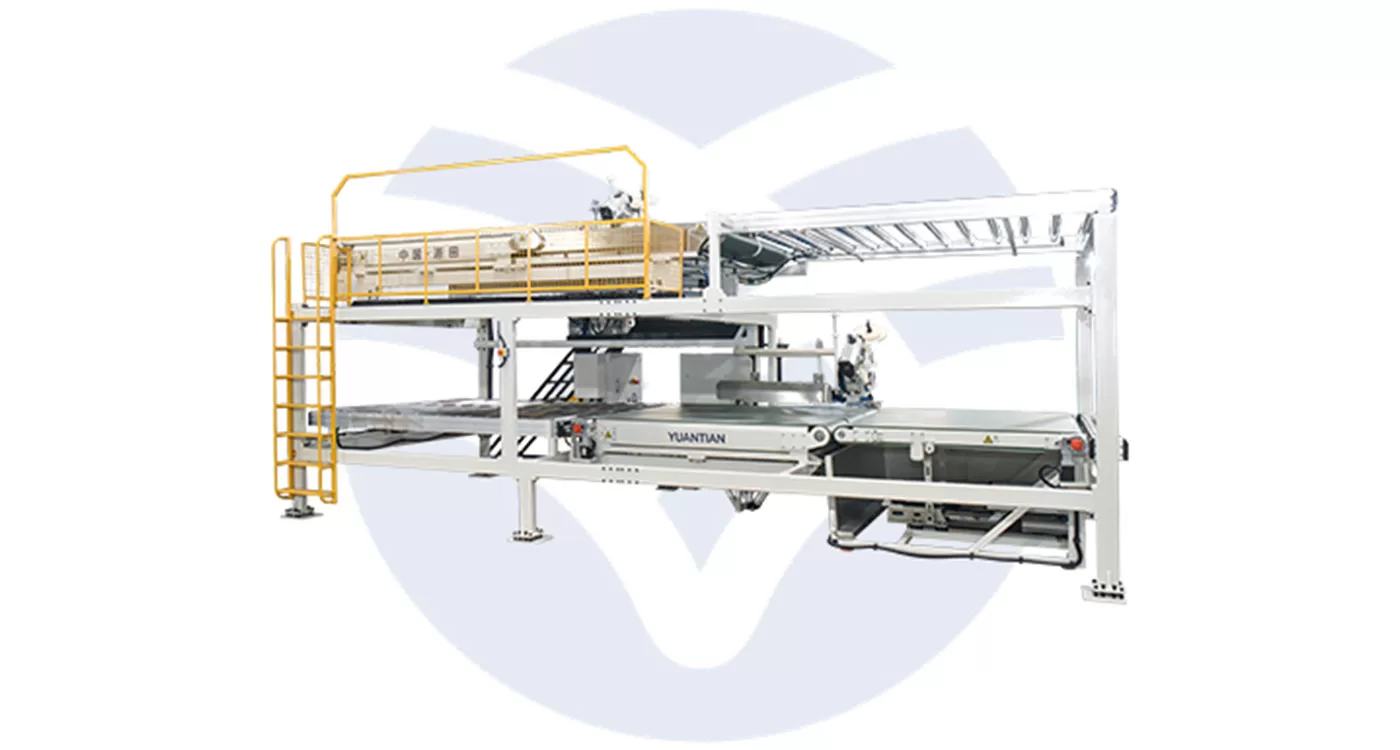

1. Operation can be completed by one person, the operator does not need to walk around the mattress, no need to manually flip the mattress, improve work efficiency.

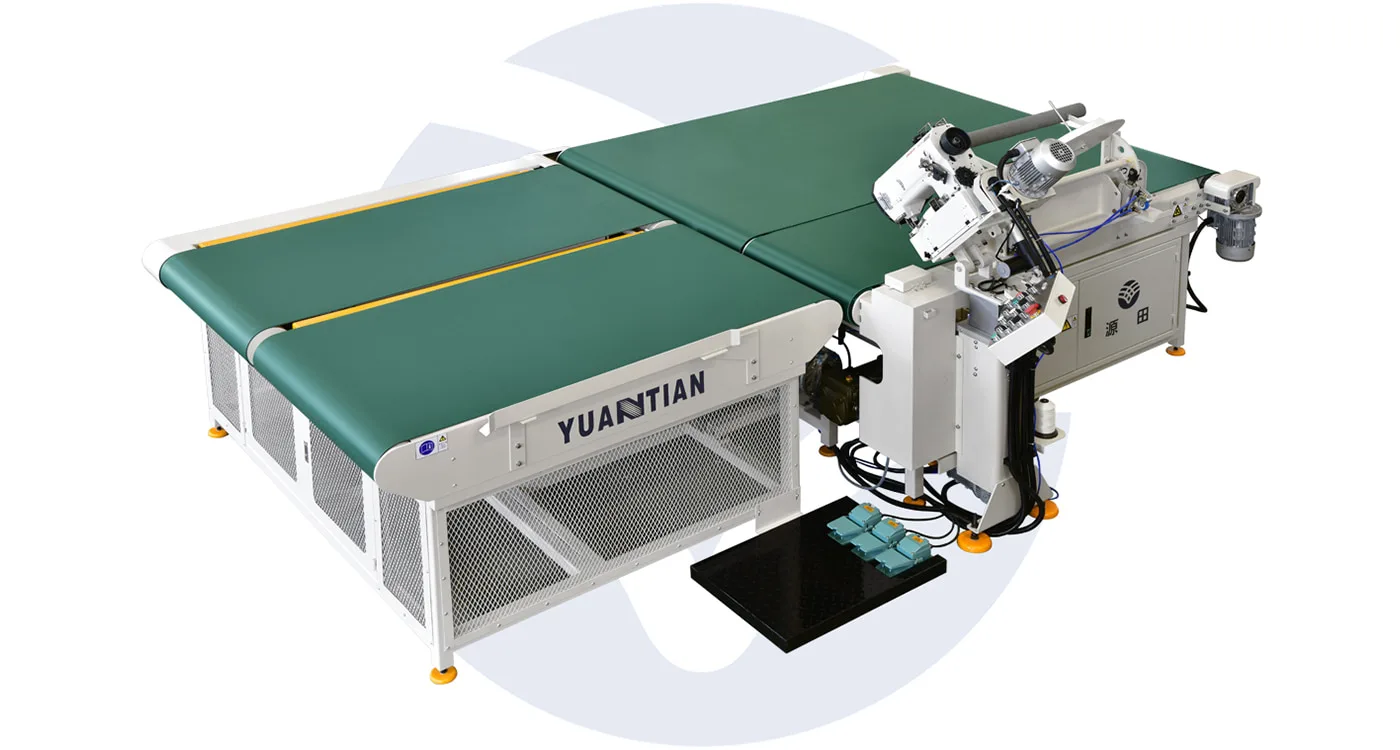

2. PLC program control, full touch – screen operation, simple interface operation, easy to get started.

3. Automatic turning function of the mattress, automatic deceleration of the sewing head when the corner is turned, automatic lifting and automatic reset, effectively improving the sewing quality and other technologies, and simplified operation.

4. Applicable mattress height is 50 – 400mm, which is suitable for a variety of specifications of mattress production line.

5. Servo motor drive, fast and accurate adjustment control, ensure sewing quality.

6. The thickness of mattress is 50mm – 400mm which is applicable to a wide range and no need to adjust the pressure arm structure, saving time.

7. Double – edge device, save floor space and make full use of the upper space, improving the unit production value.

In terms of price, we have a special quotation sheet for each machine. At the same time, we can also provide professional mattress machinery solutions and quotations according to your manufacturing needs.

If you need more information about our double layer automatic tape edge machine, please leave us a message, or contact our sales representative.

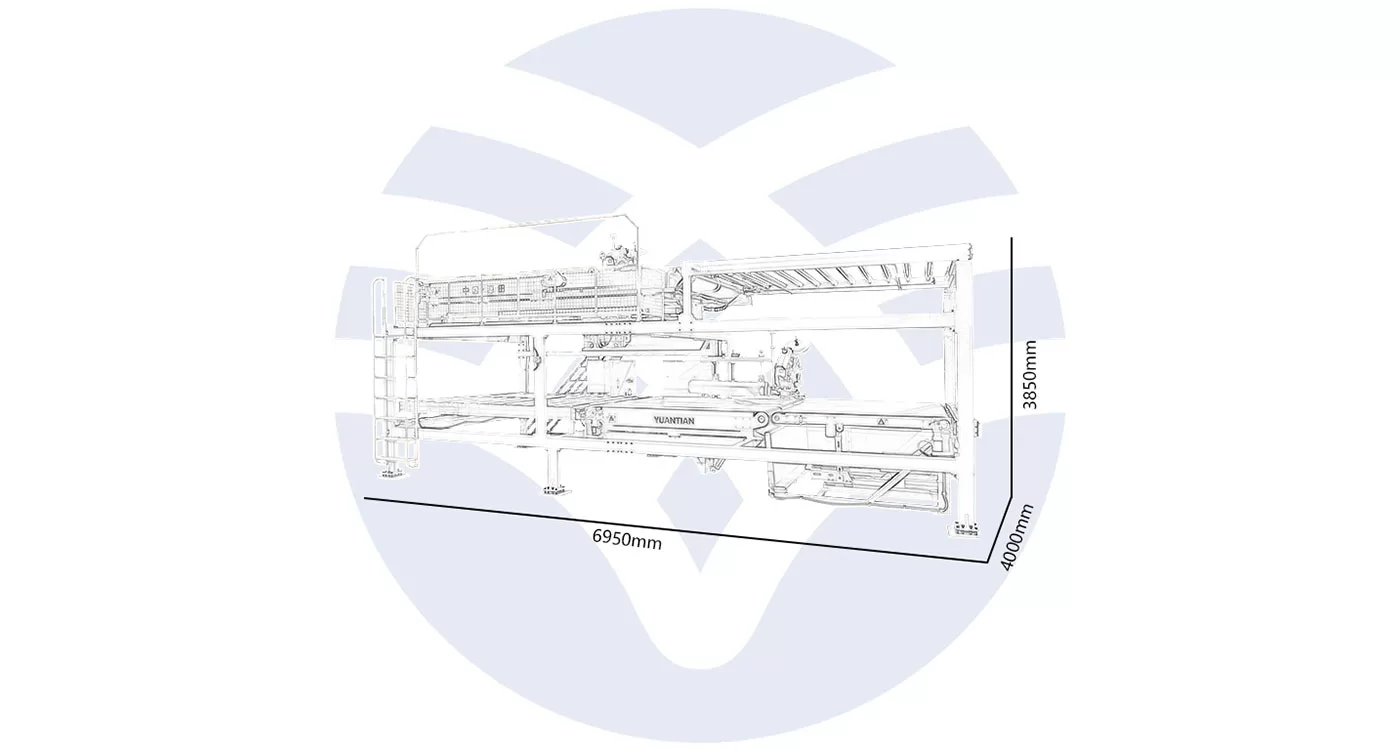

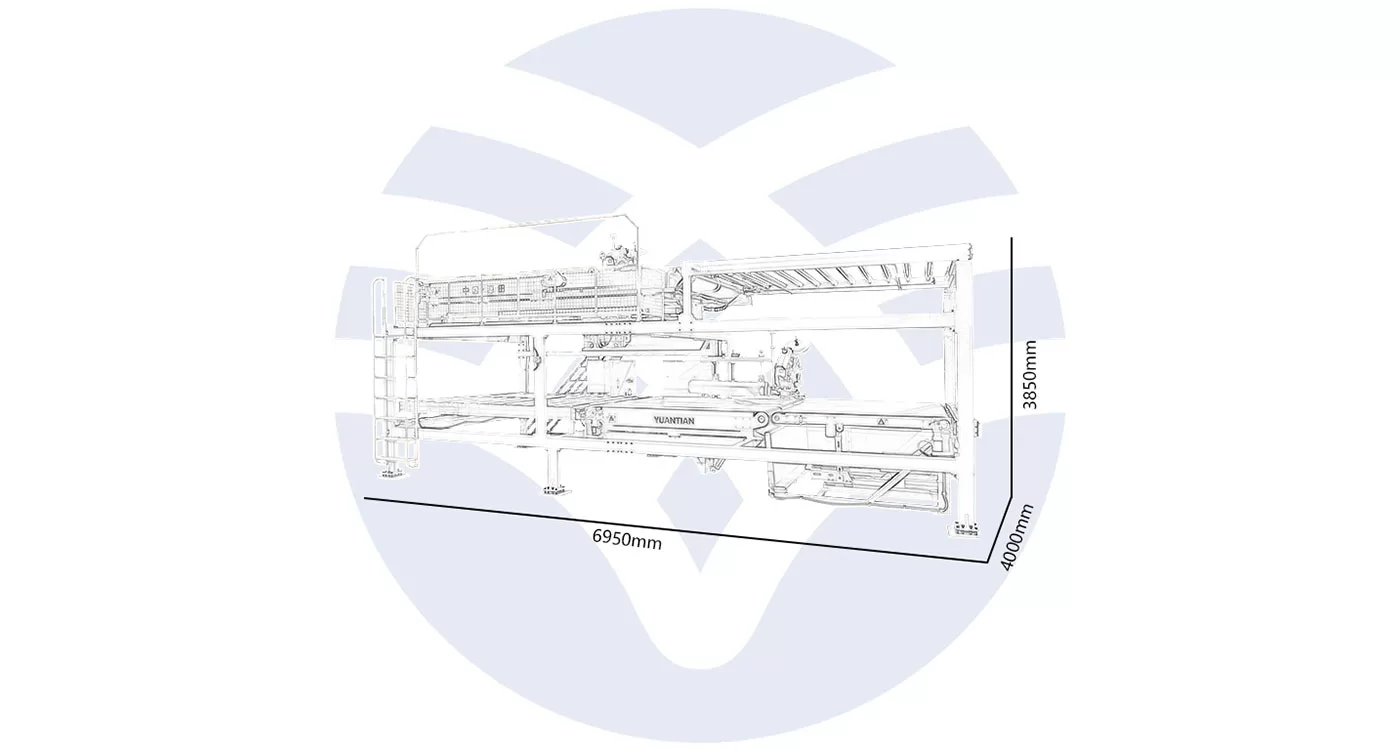

Parameters of YT-WB-6A

| Productivity | 25 – 40units/h |

| Total Power | 8.5kw |

| Thickness | 50 – 400mm |

| Power Supply | 3PH – 380v – 50Hz (Can be customized) |

| Max Rotating Speed | 2200RPM (100U); 3000RPM (PUFF) |

| Air Pressure | 0.6 – 0.8MPa |

| Angle of Sewing Head | 30° – 75° |

| Overall Dimension | 6550*4000*3850mm |

| Puppy Transmission Speed | 25 – 30m/min |