- Home » MATTRESS MACHINERY » Mattress Packaging » Mattress Packaging Machine Series » Automatic Mattress Compressing Rolling Packing Machine

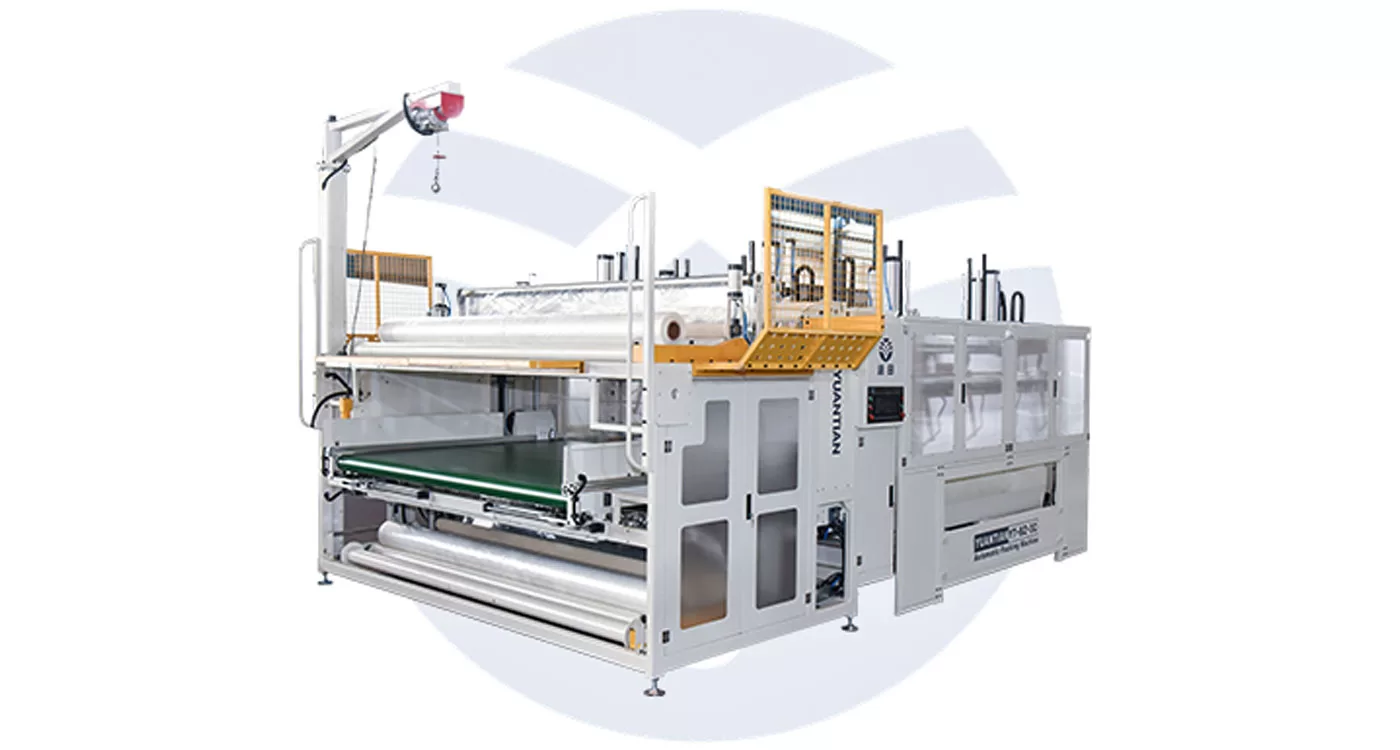

Automatic Mattress Compressing Rolling Packing Machine YT-BZ-6A

As a core piece of equipment for mattress production, this intelligent integrated packaging device relies on full-process automation technology, incorporating multiple functions such as compression, roll packaging, and sealing. It provides a one-stop packaging solution for mainstream mattresses, driving production towards greater efficiency.

The equipment achieves fully automated operations from input to output through the integration of servo and intelligent control systems. Precise compression reduces volume, while roll packaging, sealing, and film application create standardized packaging, ensuring consistent quality. Its intelligent sensing system can automatically identify mattresses made from different materials and flexibly adjust packaging parameters, seamlessly accommodating frameless independent bagged springs, foam, latex, and other mattress types, thus meeting diverse production needs and enhancing line adaptability.

The volume of the packaged finished products is significantly reduced, saving storage space and transportation costs, making it convenient for e-commerce logistics distribution. The high-strength film and sealing process effectively protect mattresses from moisture and collision damage. The modular design allows functional units to be configured as needed, adapting to the different production requirements of large, medium, and small enterprises, leaving room for future line upgrades.

This equipment not only enhances packaging efficiency and product added value for enterprises but also promotes the standardization of logistics in the mattress industry. With its intelligent and flexible characteristics, it serves as an important technological support for the manufacturing industry’s transition to “Industry 4.0.”

1. This equipment integrates mattress packaging, compression, rolling, sealing, film application, input and output into an integrated automatic packaging equipment.

2. Suitable for packaging frameless pocket spring mattresses, sponge mattresses, latex mattresses, etc.

3. The packaged finished mattress is small in size, easy to store and transport, especially convenient for retail customers to pick up goods.

4. Modular design, can customize the configuration of the machine.

Parameters of YT-BZ-6A

| Productivity | 25 – 35spcs | Applicable Mattress Size | 2200*2000*420mm |

| Power Supply | 3PH-380v-50hz | Packing Material | PE/PVC |

| Max. Packing Film Width | 2700MM | Product Diameter | 200 – 550mm |

| Total Weight | ≈15ton | Applicable Mattress Type | Pocket spring mattress, sponge mattress, latex mattress, memory foam mattress, ordinary spring mattress, Bonnel spring mattress |

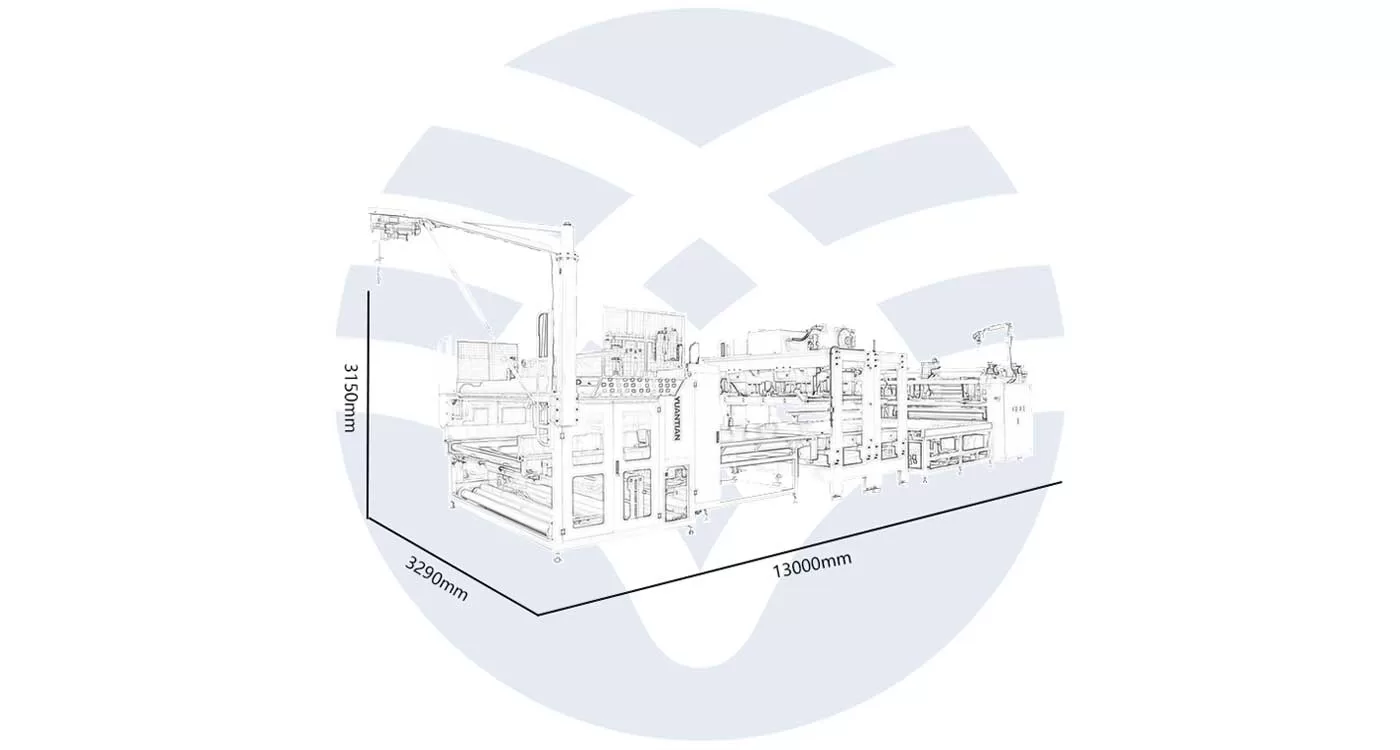

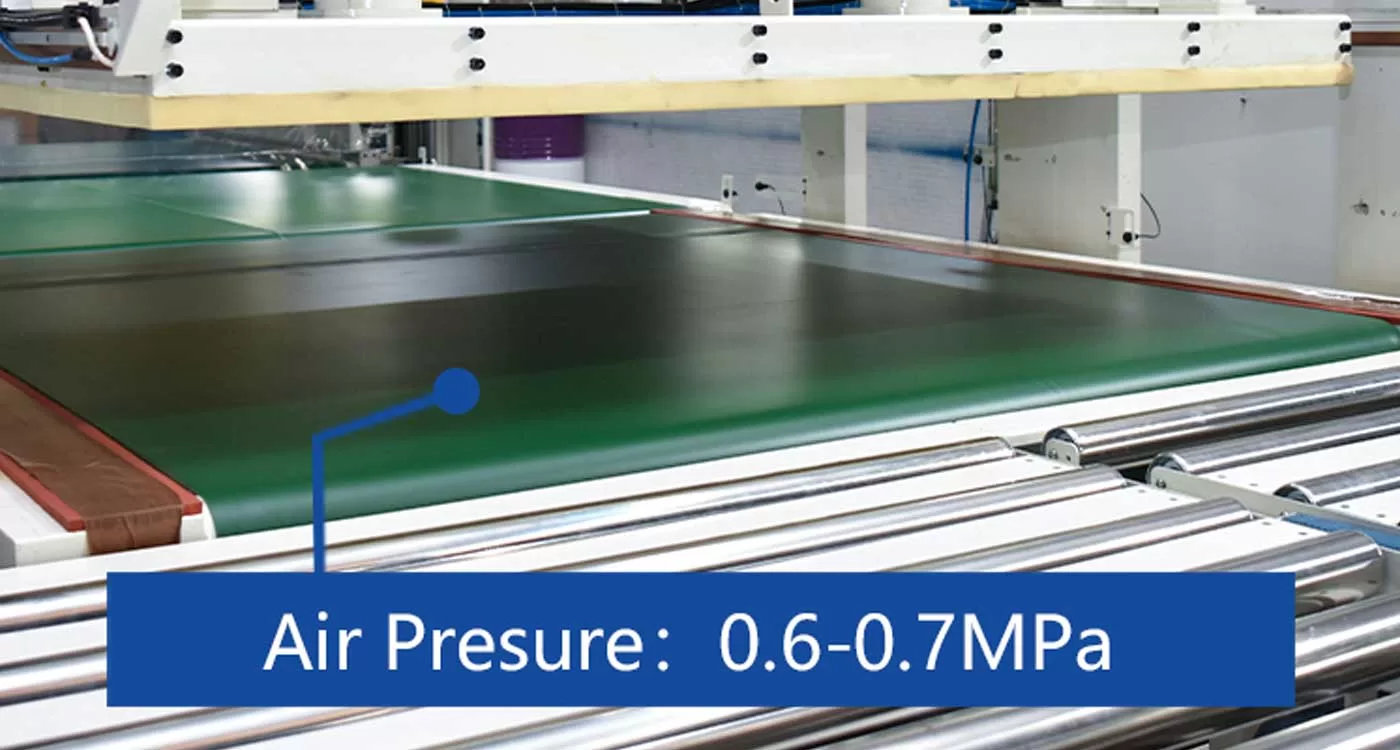

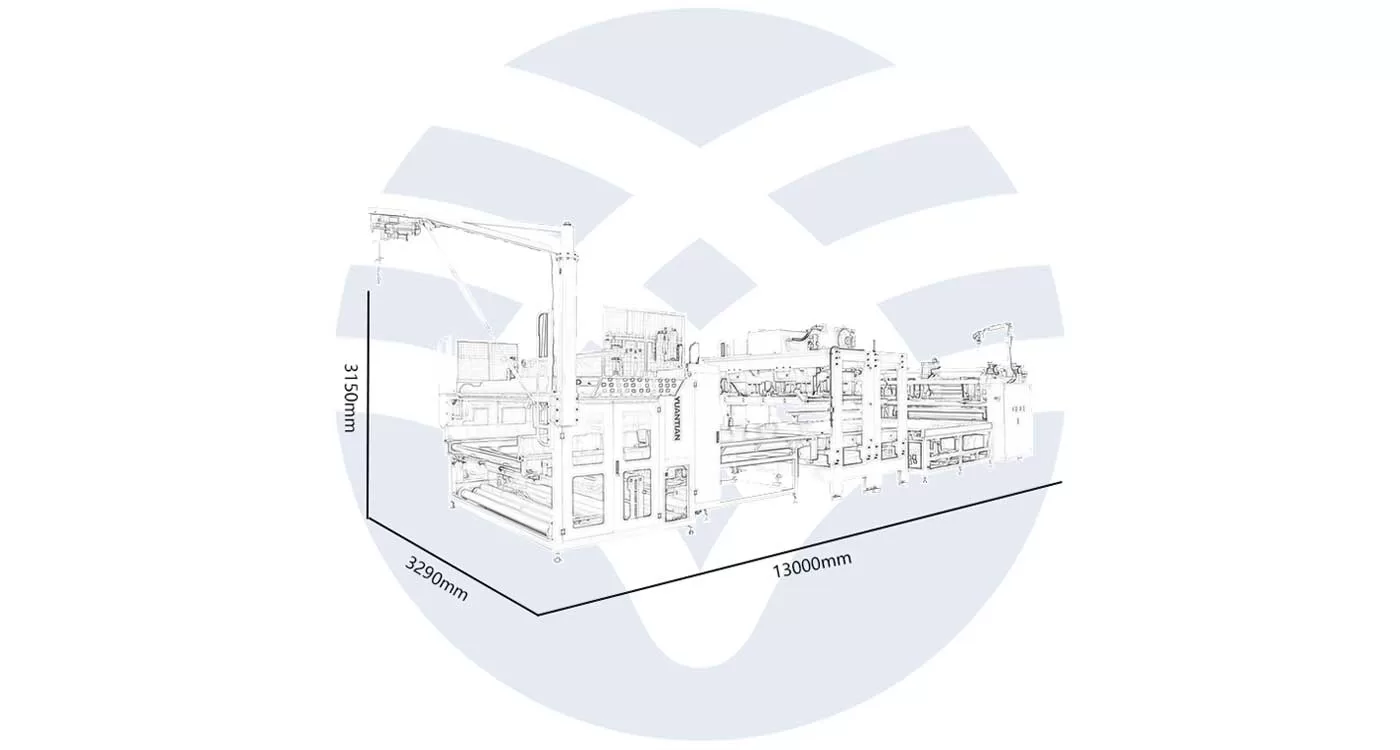

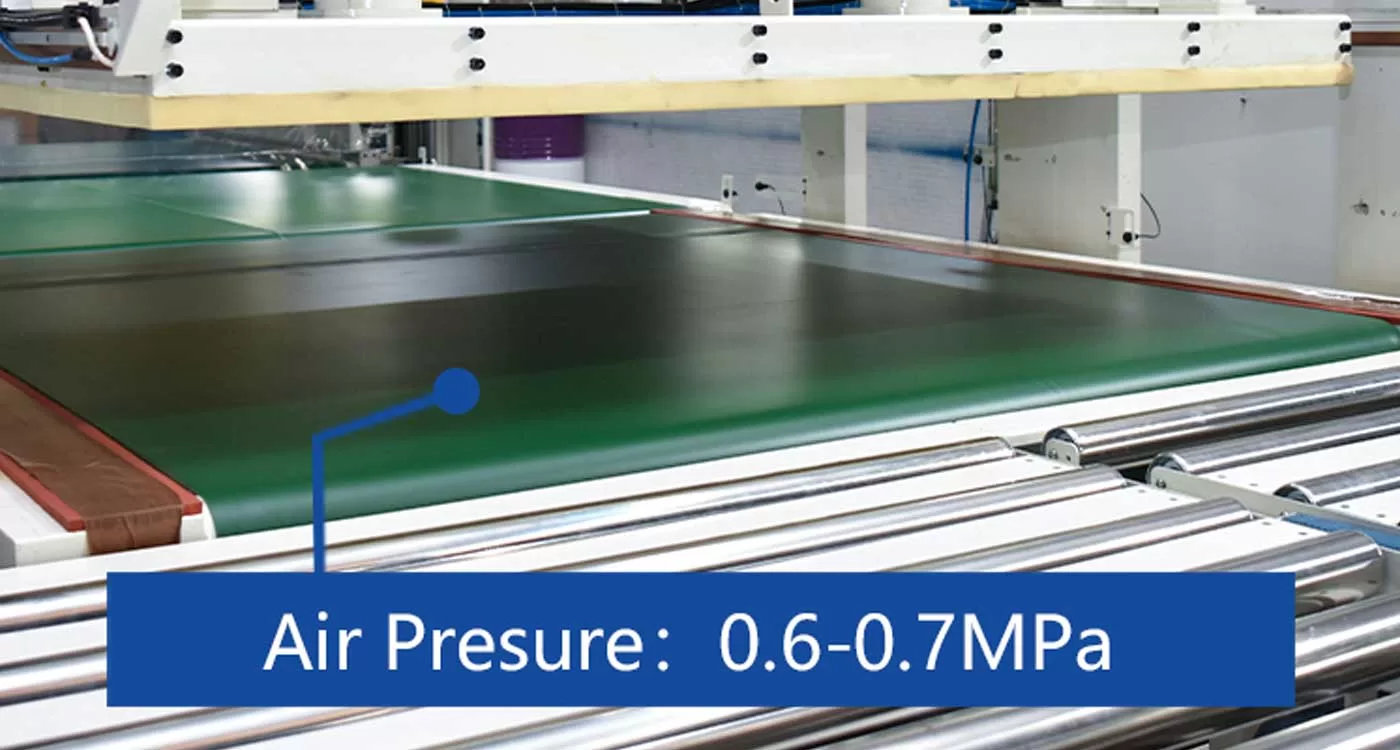

| Air Pressure | 0.6 – 0.8MPa | Overall Dimension | 12500*4200*3800mm |

| Total Power | 36kw | Packing Film Thickness | 0.06 – 0.13mm |