- Home » MATTRESS MACHINERY » Mattress Spraying Line » Automatic Mattress Spraying Line: Streamline Your Production with Precision Coating

Automatic Mattress Spraying Line: Streamline Your Production with Precision Coating YT-PJ-2A

The YT-PJ-2A Automatic Mattress Spraying Line is a customized full-automatic spraying solution developed by our company to meet specific customer process requirements, dedicated to transforming traditional spraying operations through intelligent technology. The equipment specializes in automated glue spraying for mattress production, replacing manual labor with precise and consistent adhesive application to effectively address issues such as uneven spraying and material waste, enhancing quality consistency and material utilization from the production outset.

Integrating motor-driven systems and pneumatic cylinders, the spraying line uses encoders for real-time motion tracking, combined with PLC control and a touchscreen HMI to create a highly intelligent fully automatic spraying system. Operators simply set parameters like spraying paths and glue volume via the touchscreen; the equipment then automatically adjusts the spray head position and pressure according to mattress specifications and process requirements, achieving end-to-end unmanned operation from mattress conveying to spraying completion. Its modular design enables flexible integration with upstream/downstream equipment (such as mattress production lines and conveying systems) to form efficient collaborative automated production units.

During operation, a precise flow control system ensures accurate glue dosage, minimizing material waste while preventing pollution from excessive spraying. The stable mechanical structure and low-vibration design guarantee continuous spraying, supported by intelligent fault diagnosis to reduce downtime for maintenance. Whether for mass production of standardized mattresses or customized spraying for personalized products, the YT-PJ-2A stands out with reliable automation, flexible process adaptability, and significant cost optimization, making it an ideal choice for the mattress industry to enhance spraying efficiency and quality.

1. An automated production line designed for mattress glue spraying, using an advanced control system to ensure uniform spraying, reduce glue waste, and improve spraying quality and production efficiency.

2. Adapts to different mattress specifications, with good compatibility and expandability, supporting multiple spraying tracks to meet diverse production needs.

| Air Pressure | 0.6 – 0.8MPa | Glue spray gun | 6pcs | |

| Power Supply | 3Ph380v50hz (Customizable as per customer requirements) | Glue spray track | Straight line, S-shape, Interrupted gluing | |

| Mattress Size | 2100*2200mm | Glue pump quantity | 2 | |

| Mattress Max Height | 390mm | Total Weight | ≈4.5kg | |

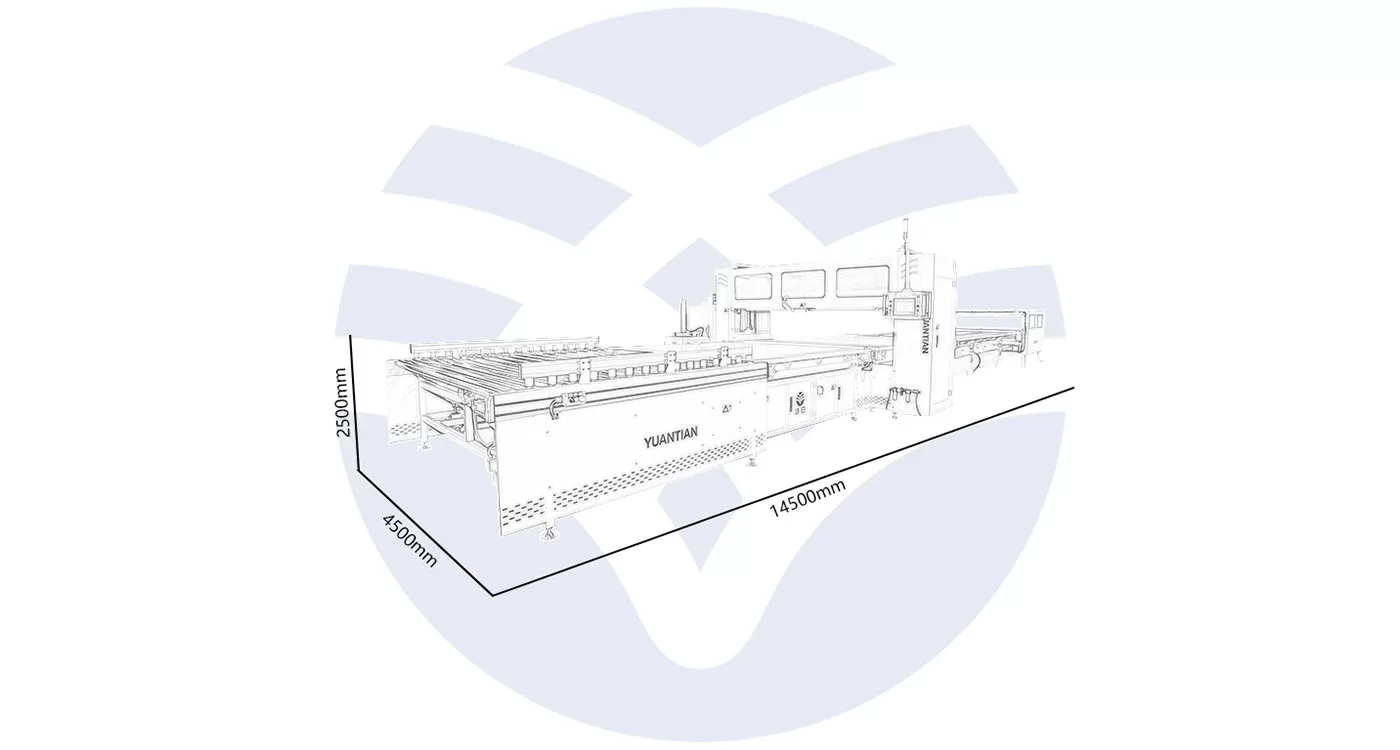

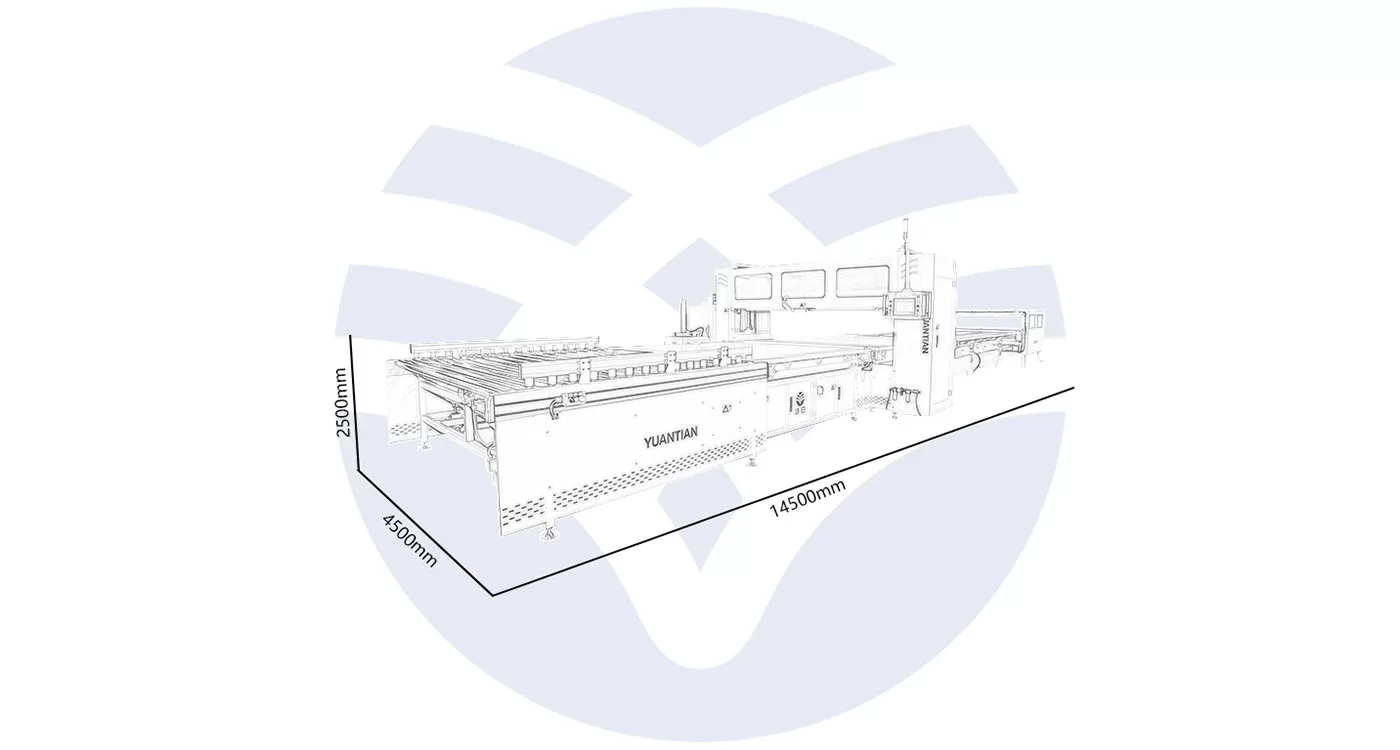

| Work Table Height | 850mm | Overall Dimension | 14500*4500*2500mm | |

| Melting Box Capacity/Power | 40L/7.2KW | Applicable products | Applicable for cotton.

mattress, felt, fabric, etc |

|

| Total Power | 17kw | Output of Efficiency | 7-105second/payer-working | |