- Home » Why Mattress Flanging Machines are Essential for High-Quality Bedding Products

People never seem to stop pursuing the best quality and durability in bedding products in the bedroom. Of all the equipment involved in the manufacture of bedding products, mattress flanging machines stand out. They form the very core of the construction of high-quality mattresses, providing precision, efficiency, and durability. This passage elaborates on how mattress flanging machines influence the quality of bedding products.

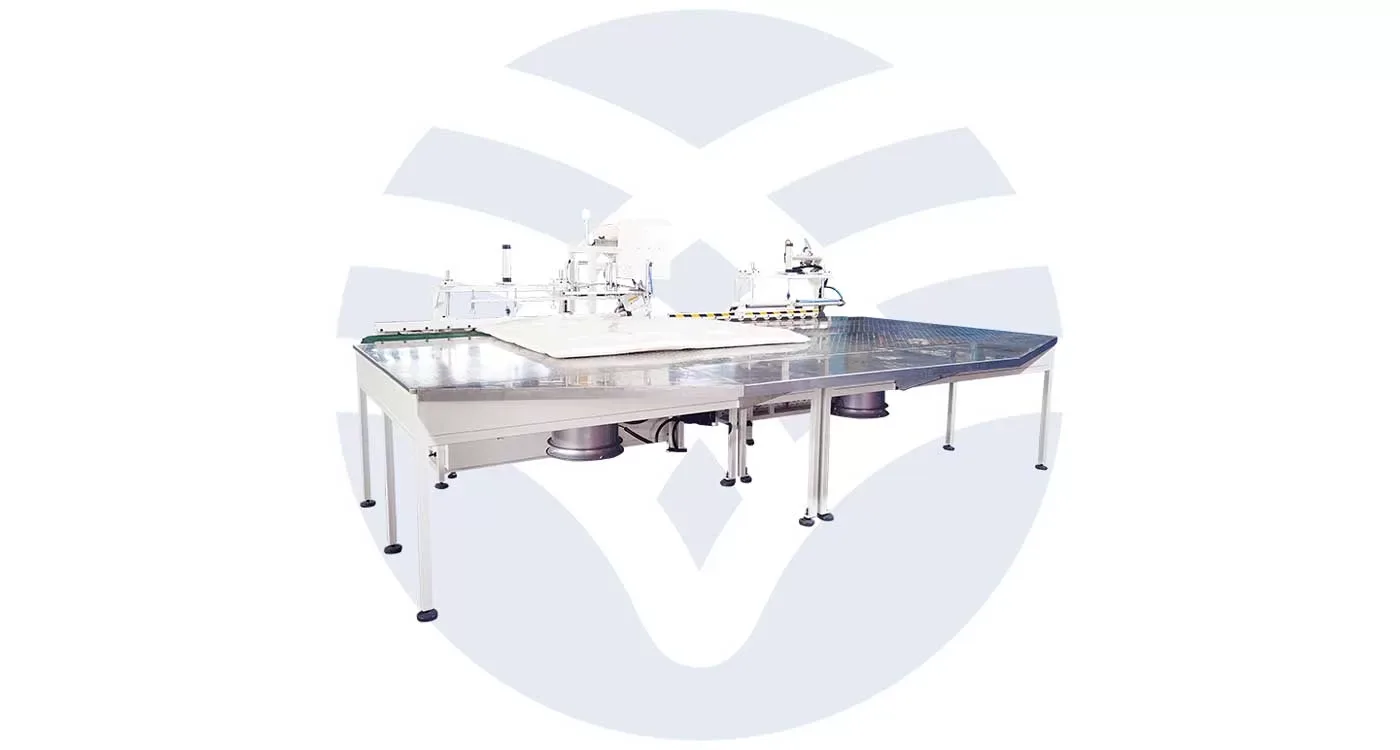

The Role of Mattress Flanging Machines

Mattress flanging machines are designed specifically to attach the borders of mattress panels at the edge of the mattress. The process of flanging is very important in the construction of a mattress—this is something that most people tend to ignore before arriving at a loose structure that would eventually fall apart. The stitching action by these machines retains the structural integrity by holding the layers from shifting or bunching.

Precision and Consistency

One of the major reasons mattress flanging machines matter is due to the fact that they are capable of delivering precision and consistency. The stitching could be managed by hand; however, this usually means variances that later turn into a variance in the quality of the finished mattress.

Flanging machines, on the other hand, are set to perform uniform stitching at specific periods. It is this type of precision that makes certain each mattress being produced happens at a similar top level of quality required by brands that promise their customers consistency.

The automated nature of the flanging machine even diminishes the scope for human error. Factors such as fatigue or variability in skill levels give way to uneven stitching, which clearly brings a negative effect on both the durability and aesthetic appeal of the mattress in the manual version of the process.

With automation, manufacturers can be assured that every mattress will meet very strict and uncompromising quality standards, thereby helping to increase customer satisfaction.

Efficiency and Productivity

Besides precision, mattress flanging machines bring increased efficiency and productivity in making mattresses. The machines are operated at high speeds, with the stitching of a large volume of mattresses taking a relatively short time. This boost to productivity is important to help makers produce to meet the high demand that exists without compromising quality.

Besides, flanging machines are cost-effective due to their high efficiency. If the preparation time for every mattress is minimized, then labor costs will drop and the output will rise. This will become very important in a competitive market where one has to balance quality with affordability to attract and retain potential customers.

Enhanced Durability

A big determinant of a mattress’ quality lies in durability, and flanging machines play a very vital role in enhancing this. These machines afford tight stitching that can hold the layers of the mattress together even after a very long time in use. This is usually one major selling point for consumers who look out for a mattress to keep them comfortable and supported for quite some time.

Furthermore, solid stitching from flanging machines aids in fending off issues such as edge breakdown and sagging. These pitfalls may prove very destructive to a mattress’s life span in service and may turn the mattress quite uncomfortable. With its strong and uniform stitching, flanging machines enhance the general life expectancy and performance of the mattress.

Improved Aesthetics

Beyond functionality, the aesthetic appeal that one considers with every mattress is great in the eyes of consumers. Mattress flanging machines add a good deal to a polished professional look by giving clean uniform stitching along the borders of a mattress. This enhances not only the look and feel of a mattress but also the quality reflected from each stitch that was invested into making it.

In a competitive market with many options to choose from, manufacturing firms need to ensure that they produce attractive mattresses. Conclusion: A sleekly finished mattress is bound to attract customers and evoke a feel-good factor for the brand. The role of the flanging machine, thus, in enhancing the look of the mattress cannot be underestimated.

Innovation and Customization

Advanced features on the modern mattress flanging machine allow manufacturers a chance to make innovations in mattress designs. The mattress stitching machines can be programmed to stitch various types of stitches and patterns, hence fabricating diverse mattresses for the manufacturer to offer in the market. This is especially important in a market characterized by buyer demands for customized bedding.

Innovation in flanging machines further goes to their incorporation with other manufacturing operations. Most of the modern-day machines can easily be integrated with quilting and embroidery machines for integrated and smooth production. This allows added efficiency and allows you to explore newer avenues for fresh mattress designs.

Environmental Impact

Nowadays, everyone in the manufacturing field is concerned with sustainability and environmental impact. Mattress flanging machines ensure that processes are more environment-friendly through the optimization of materials utilized and waste reduction. Their precision ensures that only the required quantity of thread and fabric is used, thereby giving a minimum of excess material and diminishing the ecological footprint of the manufacturing process.

Moreover, flanging machines play a major role in providing durability, which reduces the tendency of the mattress to quickly reach landfills. Bedding products that are hard-wearing will reduce trash and greatly foster greener consumption.

Conclusion

Mattress flanging machines play a key role in the production of quality bedding products. Developing a solution that can actually meet the precision, consistency, and efficiency of mattress flanging would drastically improve the quality and durability of mattresses. Not only that, but these machines also aid in enhancing aesthetics, innovation, and sustainability in mattress manufacturing.

As the bedding industry develops further, then this sophisticated machinery would be the center stage for business opportunities, able to provide a guarantee to manufacturers for keeping up with the quality standards for which this clientele is adamant, all while ensuring competitive yet sustainable production practices.

Связанные с ними товары