- Home » Which Type of Mattress Making Machine is Best Suited for Your Manufacturing Needs?

The selection of the right type of mattress making machine is a crucial decision for any mattress manufacturer. There are ample types available in the market with distinct capabilities and advantages, understanding which type is best suited for your manufacturing needs can enhance production efficiency, product quality, and overall profitability. This guide explores the various types of mattress making machines, their specific applications, and factors to consider when making your choice.

Understanding Mattress Making Machines

Mattress making machines encompass a wide range of equipment designed to handle different stages of the mattress production process. From cutting and sewing to assembling and packaging, these machines are integral to the manufacturing workflow.

Types of Mattress Making Machines

Quilting Machines

These machines bind the material layers of fabric, foam, and other materials to prepare the quilted top part of the mattress. The computerized ones would obviously be better for precision and could be used in any feathery or fuzzy fashion.

Quilting machines have very high accuracy and are versatile in the creation of complicated patterns for quilts. There is a large design flexibility and good quality in computerized forms. However, these machines can be expensive and require skilled operators. Additionally, maintaining and programming computerized quilting machines may be more complex.

Foam Cutting Machines

These machines are equipped to cut foam blocks into the desired shape and size. They vary largely, including numerous types such as horizontal and vertical foam cutters, contour cutters, and CNC foam cutters. These vary in capacities from simple slicing to very complex, custom-shaped cuts.

They are used to create foam parts very accurately. CNC cutters have a high degree of precision and can produce parts in various complex geometries. However, high-precession foam cutting machines may come at a high price. The maintenance and calibration of the machines are also important to uphold continued precision and performance.

Tape Edge Machine

Tape edge machines are used to stitch or sew variously configured mattresses around the outer edges of the mattresses. These machines come in the market as manual, semi-automatic, and fully automatic, whereby each of these categories is faster than what was mentioned before, therefore quicker to finish up customers’ orders.

Tape edge machines streamline the process of stitching mattress edges, ensuring a clean and durable finish. Automated versions increase speed and reduce labor costs. Fully automatic tape edge machines involve a huge investment. The machines are quite tough to operate and require trained operators.

Spring Assembling Machines

These machines produce innerspring units, often referred to as the heart of a mattress. There are pocket spring machines and Bonnell spring machines, both of which are used when working with different kinds of springs or with various configurations.

These machines are vital for producing innerspring units efficiently. They offer high-speed production and consistent assembly quality, particularly important for mass production. Spring assembling machines are specialized and may not be suitable for manufacturers who produce mattresses with alternative support systems. The cost of these machines can also be prohibitive for smaller operations.

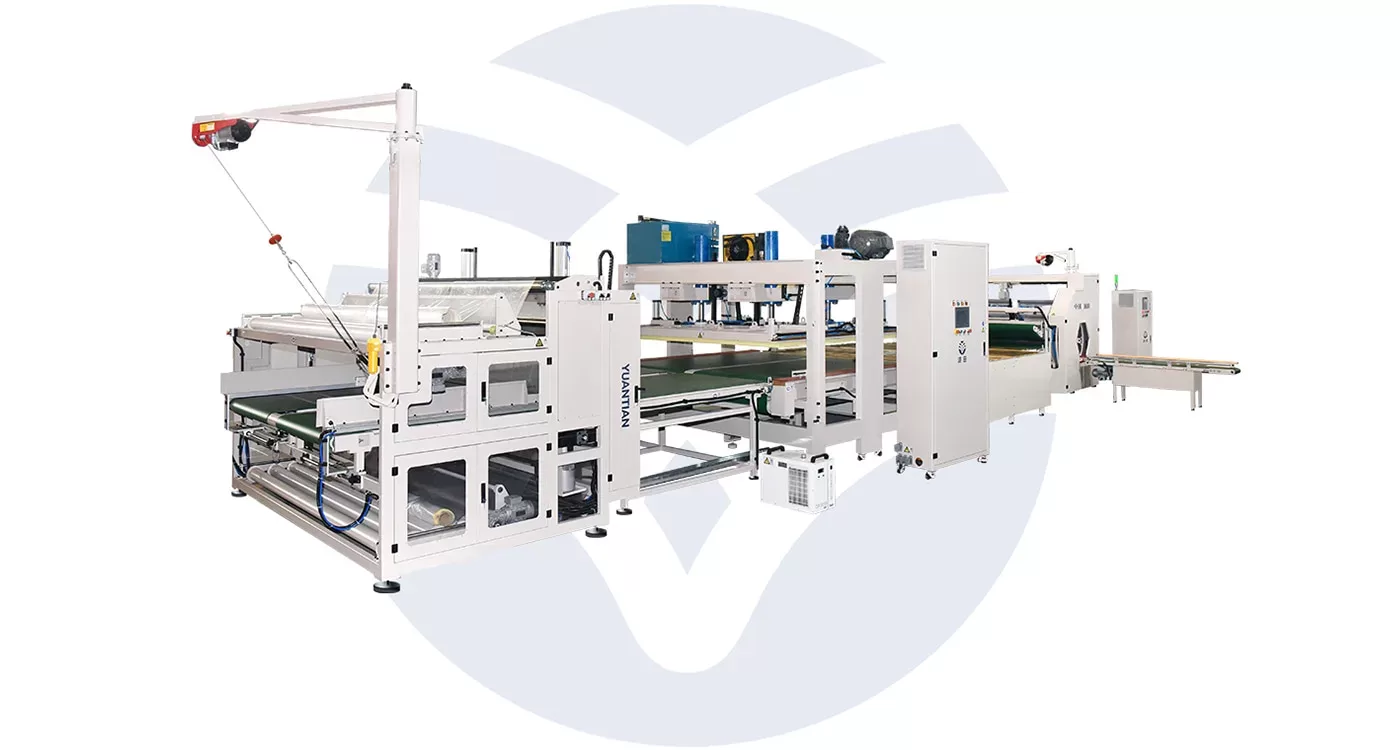

Mattress Compressing and Rolling Machines

All these machines are designed to compress and roll mattresses easily and complete the most important procedure of increasing mattress density, which reduces the cost of shipping and improves logistics.

Compressing and rolling machines provide great storage and shipping savings by compressing the stack height to the maximum possible level. Such machines would be a requirement for manufacturers keeping e-commerce in mind, or offering compact store formats. The process of compressing and rolling can sometimes affect mattress integrity if not done correctly. These machines also require regular maintenance to ensure they function optimally.

Factors to Consider When Choosing a Mattress Making Machine

Choosing the right mattress-making machine involves assessing various factors that influence your production process and business goals.

Production Volume

Low to Medium Volume Production: For manufacturers with lower production volumes, manual or semi-automatic machines may be sufficient. These machines are typically more affordable and easier to operate but may not offer the speed or precision of fully automated systems.

High Volume Production: A manufacturer who produces high volumes would be justified in employing fully automatic machines having high speed, as well as precision and repeatability. This, in turn, would result in a huge reduction in labor costs accompanied by a high increase in output, thereby justifying the higher initial investment needed for these machines.

Product Variety

Standard Products: Special types of machines organized in your plant layout as per the generic designed mattress line of standardized models will only support efficiency improvements and effectively reduce change-over times.

Customized Products: Manufacturers who offer a large variety of custom mattresses require versatile and programmable machines. With these machines, the conversion process can be fast and support different designs and specifications. This encourages customization and responsiveness to the needs of the customer.

Budget and Investment

Initial Investment: The cost of machine equipment to make mattresses is different based on the complexity, capability, and branding. Having a clear budget helps to cut down to what might be feasible within the financial capacity of the entity and yet is sufficient to meet production demand.

Operating Costs: Consider maintenance as well as energy in use and labor, apart from the cost of initial investment. While initially costing more in terms of the purchase price, cheaper long-term costs through efficiency mean saved labor via automated machines.

Quality and Durability

Machine Build Quality: A good quality machine comes out durable in the long run because of its good, solid material; its robustness in terms of construction; and its ruggedness of components. More reliable equipment aids in the minimization of downtime and maintenance, which are preconditions for keeping the quality standard of functioning continuous.

Manufacturer Support: Select machines from manufacturers who are well recognized for their support services. The support should be all inclusive, which is, from training to maintenance services, and available spare parts. Strong manufacturer support can also increase the life of the machines and prevention from expensive interruptions in production.

Conclusion

What will be the right mattress making machinery for your manufacturing requirements is indeed an important consideration and should be done through considerations with respect to production volume, mix of products that you would wish to supply in the market, budget, and quality requirements. Each kind of machinery has specific advantages and potential drawbacks, so it is really necessary for you to identify what kind of machinery would best fit the particular operational goal and constraints.

Investing in the right equipment can significantly enhance production efficiency, product quality, and overall profitability, positioning your business for long-term success in the competitive mattress market. By thoroughly evaluating your needs and exploring the capabilities of different machines, you can make an informed decision that supports your manufacturing objectives and drives growth.

Связанные с ними товары