- Home » What is a Mattress Flanging Machine?

A mattress flanging machine is a specific machine used in a mattress manufacturing line to sew or “flange” the edges of the mattress panels in preparation for further assembly.

Flanging is the process of stitching border material to both the top and bottom panels, thereby creating a smooth, reinforced edge that may now be attached to the mattress’s side panels. This process is very important for the structural strength, beauty, and class of the final mattress.

For a manufacturer to produce quality mattresses in a cost-effective and time-efficient manner, they will have to understand what it entails to operate a mattress flanging machine and have knowledge about its components, applications, and advantages.

Components of a Mattress Flanging Machine

Various components constitute the mattress flanging machine and are very instrumental in the production of the mattress flanging process. They include:

1. Sewing Head: The head of the flanging machine is installed with a needle, bobbin, and thread mechanism for stitching. The sewing head can be adjusted to take up varying thicknesses of material and put out variable stitching.

2. Needle Assembly: This is the part made up of the needle, presser foot, and feed dogs of this sewing machine. The needle assembly travels up and down, piercing the fabric to create stitches; the presser foot is associated with holding the material, and the feed dogs move the fabric through the machine.

3. Thread Tension Mechanism: This will produce tight, even stitches. A tension mechanism will enable the machine to regulate the thread’s amount of tightness around the fabric; hence, the stitches produced will be even and tight.

4. Fabric Feeding System: The fabric feeding system guides the mattress panels through the machine. This is composed of system rollers, belts, and guides that enable the material to be fed in ways that are smooth and even without bunching up or pulling.

5. Control Panel: This allows the operator to set or adjust parameters of the machine like stitch length, speed, and tension. Modern-day flanging machines come with a lot of sophistication and are provided with control panels that allow fine-tuning and programmable stitch patterns.

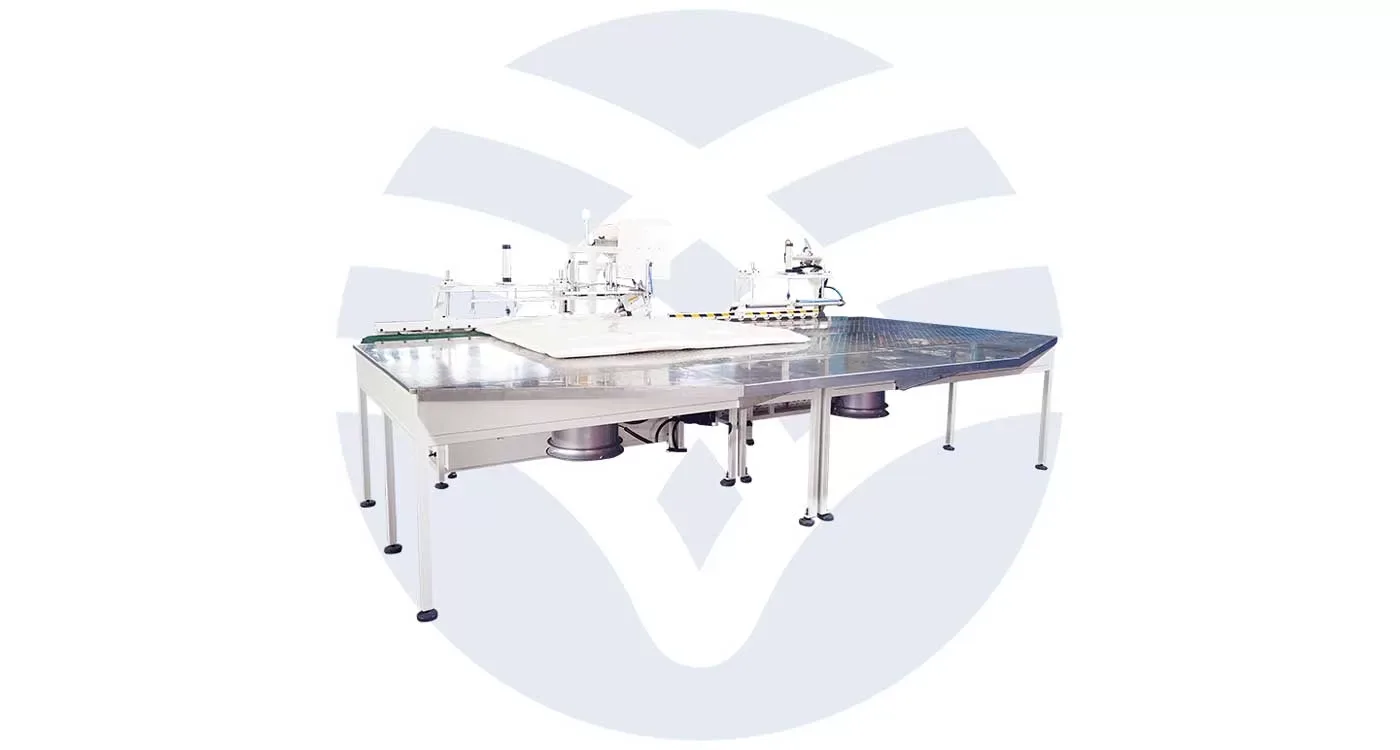

6. Frame and Table: The frame supports the whole machine while the table provides a flat resting surface on which the material rests as it moves forward through the sewing head. The frame and table require rigidity and firmness to provide correct stitching.

How a Mattress Flanging Machine Works

The function of a mattress flanging machine entails the following steps:

Setup

Put a needle into the machine and load the bobbin, at the same time giving the necessary tension and pressure on the feet of the material depending on the type of fabric and sewing technique. Then line up the mattress panels on the table, ready to be fed through the machine.

Feeding the Material

The fabric feeding system directs the panels under the sewing head. Proper alignment of the material is the responsibility of the operator to sew straight and even stitches along the edges.

Stitching

Following its progress through the machine, the stitching assembly made out of the fabric starts adding edge material to the top and bottom panels. The sewing head itself is adjustable to make straight, zigzag, or lock stitches, depending on the type of finish.

Inspection and Adjustment

The stitched edges, after flanging, are passed to the inspection stage. While corrections are made to any loose threads and not-so-good stitches, machine settings are adjusted respectively.

Applications of the Mattress Flanging Machines

The mattress flanging machines can be applied to a wide range of processes in the manufacturing of mattresses and specifically in the production of innerspring mattresses, foam mattresses, and hybrid models. Some of the common applications are:

Innerspring Mattresses

Mattresses of this category have a support framework of metal coils. The flanging machine stitches the quilted panels with border material, which is then fastened to the coil unit. By this process, fabric layers are prevented from creeping, and the coil gets a complete enclosure.

Foam Mattresses

These mattresses have a built-up structure of foam, including memory foam and latex. Our flanging machine reinforces edges with the foam layers more easily so that, in turn, the creation of the edges encased into the outer fabric and holding will be easier.

Hybrid Mattresses

These mattresses comprise innerspring coils with foam or latex layers. Flanging machines perform in stitching several materials together to ensure the mattress holds up its components to become a comfortable sleeping surface area.

Pillow-Top Mattresses

Pillow-top mattresses have an extra layer of padding sewn to the top. Flanging machines sew the pillow-top layer onto the core mattress; the new layer of padding is used to create a soft and cozy surface upon securing it in place.

Benefits of Using a Mattress Flanging Machine

The use of a mattress flanging machine offers several benefits for manufacturers, contributing to improved product quality, increased efficiency, and reduced labor costs. Some key advantages include:

Enhanced Durability

In flanging, the edges of the mattress panels are retained and, thus, they are not exposed to raveling. This makes the mattress much more durable and also lasts longer.

Improved Aesthetics

Flanging results in smooth and edge-to-edge evenness that hugely improves the appearance of the mattress. This really counts in the high-priced mattresses when the aesthetics of the product stand critically for public acceptance.

Increased Efficiency

Flanging machines, with automation, process materials consistently and easily in high quantities in a short time. Increased production throughput is, therefore, achieved with relatively shortened production time, which is most helpful to a manufacturer under high pressure from the market.

Cost Savings

Since manufacturers can automate the flanging process, they can reduce their labor costs by a significant amount and also avoid human errors in the process. This reduces production costs and thus increases profit margins for the manufacturers.

Versatility

Modern machines used to make flanges are versatile and can be applied to a wide choice of materials and stitching patterns; this unpacks a myriad of possibilities for manufacturers to make different mattress types and tailor their products to customers’ tastes.

Technological Advancements in Mattress Flanging Machines

The development in technology has greatly impacted mattress flanging machines, making them efficient, accurate, and user-friendly. Some of the remarkable improvements in technology are as follows:

Computerized Control Systems

Most modern flanging machines are equipped with computerized control systems that guarantee variable adjustment and pre-programmed stitching patterns. These systems enhance the process of flanging in terms of accuracy and consistency.

Automatic Thread Cutting and Tension Adjustment

The latest flanging machines are integrated with automatic thread cutting and tension adjustment features, thus reducing manual interference and ensuring the same quality of stitching.

Remote Monitoring and Diagnostics

Some flanging machines feature remote monitoring and diagnostic capabilities that enable real-time supervision of the working performance of the machine and, therefore early detection of problems. This, in turn, minimizes downtime and maintenance costs.

Conclusion

A mattress flanging machine holds significance for the manufacturing process of a mattress. It provides a mattress panel with reinforced edges that are also aesthetic. If a manufacturer knows the components, mode of operation and areas of application of such machines then efficiency in production and quality of the product can be enhanced.

Technologically superior mechanisms to get better performance from flanging machines are also making them more functional and adaptable, turning them into a must-have for manufacturers in the competitive mattress market. With proper use and maintenance, mattress flanging machines can significantly contribute to the production of high-quality mattresses that meet the diverse needs of consumers.

Связанные с ними товары