- Home » Understanding the Stitching Process in Mattress Flanging Machines

The mattress manufacturing process involves a number of very important steps to ensure that the final product is durable, comfortable, and good-looking. One such process is flanging: stitching the panels of the mattress to the border material in order to create a safe and seamless edge.

Flanging helps reinforce the structural integrity of the mattress and ensures that the internal components stay in place over time. Stitching is the most crucial part of the entire process. The paper discusses the stitching process in mattress flanging machines: how it works, stitching techniques, and the aspect of precision that ensures quality and durable mattresses.

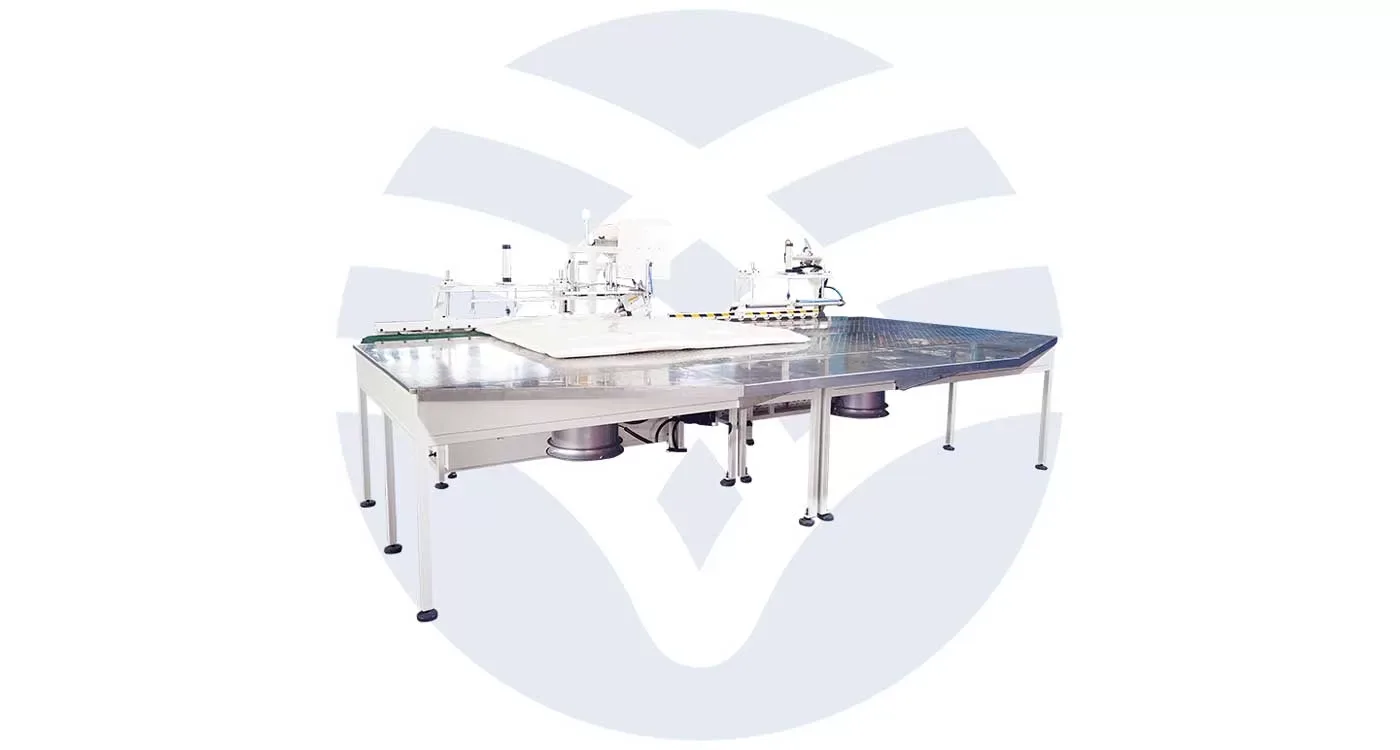

Overview of Mattress Flanging Machines

Mattress flanging machines are specialty equipment designed to sew the edge of a mattress panel to its border fabric. Unlike most sewing machines, flanging machines have been engineered to handle thick materials and multiple layers for strong and durable stitching.

Purpose of Flanging in Mattress Construction

Flanging is a very important part of the process in mattress construction, where the top and bottom panels are attached to the side borders. It acts like the outer shell of the mattress in that it encapsulates the interior layers-such as springs or foam, preventing them from shifting out of place or misaligning.

Without flanging, the mattress would not have any structural cohesiveness to it, which would cause faster wear and tear. Sewing these panels to the border fabric will make the mattress very strong (including its edge reinforcement) to withstand daily use.

Types of Mattress Flanging Machines

Several types of mattress flanging machines have been developed for different production needs. The most common are:

Manual flanging machines require the operator to guide the fabric through the machine manually. These are more suited for smaller manufacturers or custom orders. Semi-automatic flanging machines offer some degree of automation but still require manual intervention.

Fully automatic flanging machines, which provide the highest level of automation, with computerized controls that guide the stitching process without human intervention. These machines are ideal for high-volume production environments.

Modern flanging machines are often equipped with advanced features, such as computerized control systems, automatic thread cutters, and material feeders, which streamline the stitching process and improve productivity.

The Stitching Process in Mattress Flanging

Stitching in mattress flanging is a specialized operation, with thick and multilayered materials to be handled, like fabric, foam, and spring covers. These stitches also function in holding the edges of those layers securely together so as not to fray or unravel.

Materials Used in the Flanging Process

In mattress flanging, the involved materials are heavy fabrics, padding, and often foam or springs that need to be encased securely. Usually, the fabric used for the border is of a very high-strength type because it has to bear high tension. Similarly, threads used for flanging are thicker compared to ordinary ones, since these need to be more durable and strong in order not to lose their stitches over a while.

Since it is a combination of these thick materials with the need for precise stitching, it becomes very unique compared to other forms of stitching.

Types of Stitches in Mattress Flanging

Mattress flanging is made up of various types of stitches that are used for specific functions and advantages. Two commonly used stitches include:

Chain Stitch: The chain stitch is a succession of unbroken loops that merge into one another, thereby making a strong yet supple seam. It is one of the very usual stitches utilized by the flogging machine because such stitches give a firm grip, which is necessary for binding thick materials together. Chain stitches give leeway to stretchiness, which is very important in mattress edges that are subjected to quick compressions and displacement.

Lock Stitch: Another common stitching technique used in mattress flanging is the lock stitch. This stitching is done out of the interlocking of two threads-one from above and one from below the fabric. The seam is much more secure, however, it does not allow as much give as a chain stitch does. Thus, lock stitches are often preferred on those areas of the mattress that need to have a rigid and firm edge.

Stitching Mechanisms in Flanging Machines

Such flanging machines have heavy-duty needles along with thread systems capable of bearing that much thickness and toughness inherent in mattress materials. Stitching will usually include a compound feed system in which the top and bottom fabric layers are moved uniformly through the machine, negating slipping or uneven stitching that can compromise the quality of the mattress edge.

Some flanging machines also offer programmable stitch length controls, allowing the manufacturers to vary spacing according to the thickness of the fabric or as per appearance requirements. This could be the case where closer stitches are used for reinforcement and longer stitches are used for aesthetic functions.

The Importance of Precision in Flanging

Precision in the mattress flanging process is indispensable because minute errors in stitching easily inflate into massive problems in the final product. Undulating stitches, loose strings, or misaligned panels weaken the structural integrity and can cause product failures like an uneven surface or premature wear.

Ensuring Uniformity in Stitching

Stitching should be uniform for both good looks and functional reasons. Uneven stitches or misaligned edges tend to make the mattress look unprofessional, it might even affect its comfort level. Flanging machines are made in a way that allows them to respond to precise controls so that every stitch falls equidistantly, accurately, and is well-secured. The automated machines make use of use of computerized systems to regulate the stitch length, tension, and speed to minimize errors.

Preventing Material Shifting During Stitching

One of the most common problems encountered in mattress flanging is to avoid shifting the layers of material during the stitching operation. Due to the shifting, it will result in either an uneven edge or weak seams, reducing the durability of the mattress.

To counteract this, flanging machines have a synchronized feeding mechanism that moves all the layers of material at the same speed and direction. This ensures the fabric layers are properly aligned and consistent, as they are stitched together in a light, even seam.

Innovations in Flanging Machines: Improving Efficiency and Quality

Modern mattress flanging machines mean improvements in both the efficiency and quality of stitching. Innovations ranging from automation to novelties in material handling give modern machines greater flexibility and control for manufacturers.

Automation and Computerized Controls

One of the key developments in flanging machinery is the addition of computer controls. While these systems make programming certain stitch patterns, adjustments to stitch lengths, and even, on occasion, allow real-time viewing of machine performance, this automation reduces manual adjustments and allows more accurate flanging.

Automated Thread Cutting and Material Feeding

Besides stitching controls, most modern flanging machines have an auto-thread-cutting mechanism that eliminates manual intervention between any two stitch sequences. Material feeding systems are motorized to ensure that layers of fabrics are fed to the machine with perfect alignment, further reducing the chances of errors and speeding up production.

Conclusion

The stitching process in mattress flanging machines is a critical component of mattress manufacturing, providing the structural support and durability needed for high-quality products. By using specialized materials, advanced stitching techniques, and precision-controlled mechanisms, flanging machines ensure that the mattress edges are securely stitched to prevent fraying or damage over time.

With innovations in automation and computerized control, modern flanging machines continue to improve production efficiency, making it easier for manufacturers to produce durable, high-quality mattresses that meet consumer demands.

Связанные с ними товары