- Home » Understanding the Different Types of Mattress Machinery

The mattress manufacturing industry relies heavily on specialized machinery to produce high-quality mattresses efficiently. These machines, each designed for specific tasks, play a crucial role in the overall production process. Understanding the different types of mattress machinery is essential for anyone involved in the mattress manufacturing industry or those looking to invest in this sector.

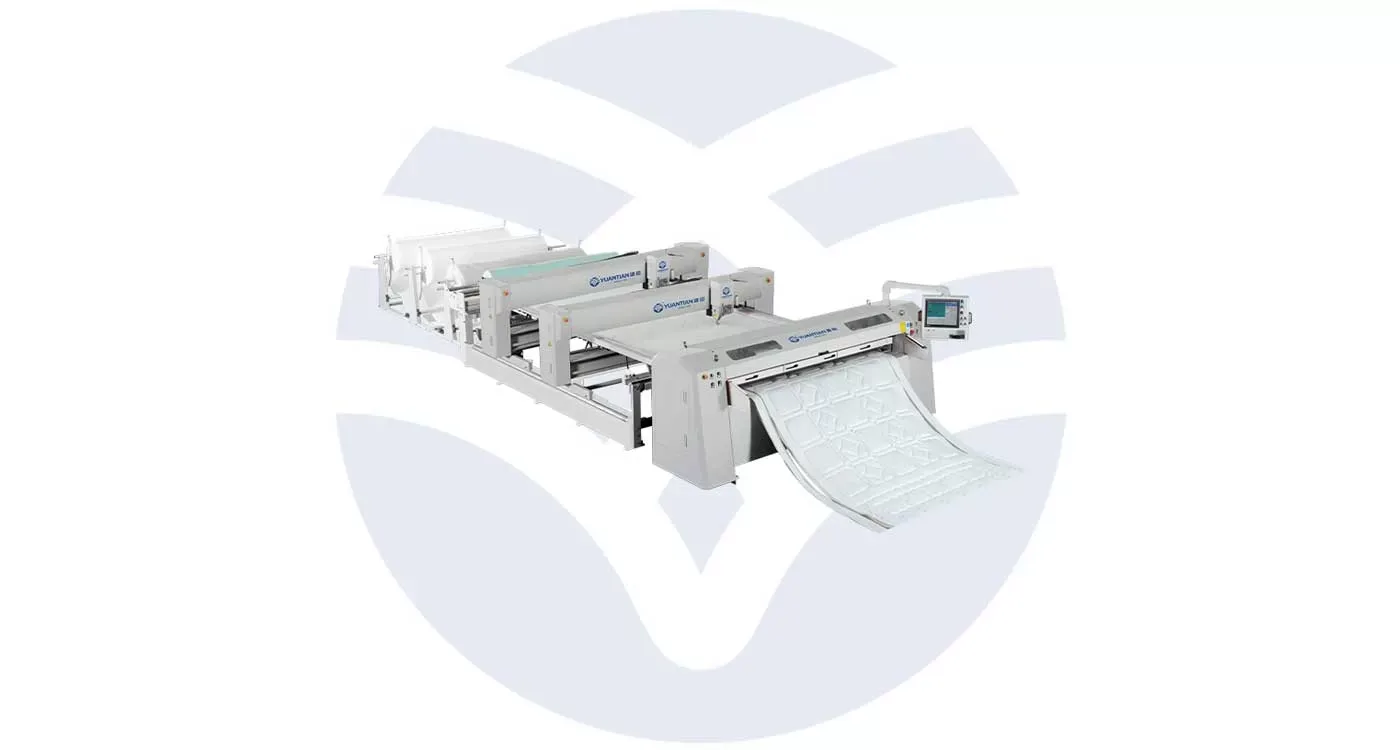

Quilting Machines: Stitching Comfort into Every Mattress

Quilting machines do the first step involved in mattress production, where stitching together the outer fabric layers with inner padding is their task. Thus, it forms the top surface of the mattress which is known for its comfort and appeal.

Multi-Needle Quilting Machines

Multi-needle quilting machines are made for volume production. They contain multiple needles that simultaneously stitch, following comprehensive patterns across the full surface of a mattress. These machines retain their prestige of speed, precision, and accuracy, making them ideal for any manufacturer who wants to make many mattresses in less time.

Single-Needle Quilting Machines

However, unlike multi-needle machines, single-needle quilting machines are best suited for small-scale production or tailor-made orders. These machines allow flexibility in the design process for manufacturers to give special patterns or designs. Single-needle machines are much slower compared to multi-needle machines but provide better options for customization.

Border Machines: Crafting the Edge of the Mattress

Another critical component, which involves special machinery, is the mattress border that forms the sides of the mattress. Border machines work in the production and attachment of this edge to ensure that through time, the mattress will hold its shape and structure.

Tape Edge Machines

Tape edge machines sew the mattress edge to the head and foot panels of the mattress. Beyond just securing various layers of the mattress, they give a finished look to the mattress as such. Tape edge machines are available in the market either in a manual or an automated version. The automatic version will be favored, especially if production rates are to be higher.

Border Quilting Machines

As the machines used for stitching designs on the top surface of the mattress, border quilting machines sew designs into the border of the mattress. This forms an added layer of detail and comfort on the mattress and increases its attractiveness. Border quilting machines can come with different configurations of needles to achieve varied patterns.

Foam Cutting Machines: Shaping the Core of the Mattress

The most important ingredient in modern mattresses, apart from offering support, is the foam. Manufacturing mattresses requires that blocks of foam should be cut into a particular shape and size, and large blocks are to be managed by machines.

Horizontal Foam Cutting Machines

The horizontal foam cutting machines cut large blocks of foam horizontally. This implies that the manufacturer is capable of making sheets of foam with diverse thicknesses, all for different layers of the mattress. These machines are extremely important because their production is used for comfort layers placed above the core of the mattress.

Vertical Foam Cutting Machines

Conversely, vertical foam cutting machines cut the blocks of foam vertically. This is very useful for giving the foam its side and edge shapes, integral parts of the whole mattress structure. The specific shapes required for more complicated mattress designs can also be created with a vertical cutting machine.

Spring Coiling Machines: Crafting the Supportive Core

Innerspring mattresses rely on a network of springs for support. The coiling machines are those which create such springs possible. These machines coil steel wire into springs in a variety of sizes and tensions before being assembled into the core.

Pocket Spring Machines

Pocket spring machines are designed to manufacture pocket springs, which are individually wrapped coils that operate independently from one another. This kind of spring system offers superior support and motion isolation, making it a popular choice for high-end mattresses. Pocket spring machines are highly automated, capable of producing hundreds of springs per minute.

Bonnell Spring Machines

Bonnell springs are an older variety of mattress spring, which take on the shape of an hourglass. Machines producing bonnel springs create these springs and subsequently link them together in one cohesive unit. Not as advanced as pocket springs, many lower-end mattresses use bonnell springs.

Mattress Assembly Machines: Bringing It All Together

When all the components are ready, then comes the time to assemble the mattress. Mattress assembly machines are specifically aimed at facilitating this process by building every mattress efficiently.

Glue Machines

Glue machines help bond different layers of the mattress together. From foams, fabrics, and other various materials, these adhesive machines apply it in such a manner that they should stay put. Glue machines come in very many configurations from very specific machines accommodating only one type of adhesives, to more versatile machines that can accommodate different types of adhesives.

Flanging Machines

The flanging machines join the mattress panels to the border without seams. This is normally done by attaching a flange or lip sewn onto the edge of the mattress panel, which is stitched to the border. The flanging machines are crucial in ensuring the mattresses hold their shape and construction over time.

Packaging Machines: Preparing for Distribution

After the mattress is fully assembled, it is supposed to be packaged and distributed. Packaging machines are designed in such a way that they can wrap and compress the mattress for easy transportation and storage.

Roll-Pack Machines

A typical example of such machines is the roll-pack machine, these machines press and roll mattresses to the smallest size. Mattresses that are sold through e-commerce channels and have to be shipped directly to customers can be tightly rolled by the machine. Consequently, the mattress size is reduced greatly, which allows the reduction of costs of transport.

Bagging Machines

After this, the mattresses are put through a bagger machine that encases the mattress in protective plastic to keep it clean and dry while it is being moved around. It also gives the mattress that professional touch. The different sizes of mattresses can be fit into the machines by readjusting the baggers.

Conclusion

The mattress manufacturing process is complex and requires a variety of specialized machines to ensure that each mattress is made to the highest standards. From quilting machines that create the top surface of the mattress to packaging machines that prepare it for distribution, each type of machinery plays a crucial role in the production process.

Understanding these different types of mattress machinery is essential for anyone involved in the mattress industry, as it allows for better decision-making and investment in the right equipment. Whether you’re a manufacturer looking to optimize your production line or an investor exploring the mattress industry, a solid understanding of these machines will serve you well.

Связанные с ними товары