- Home » Understanding the Basics of Mattress Quilting Machines

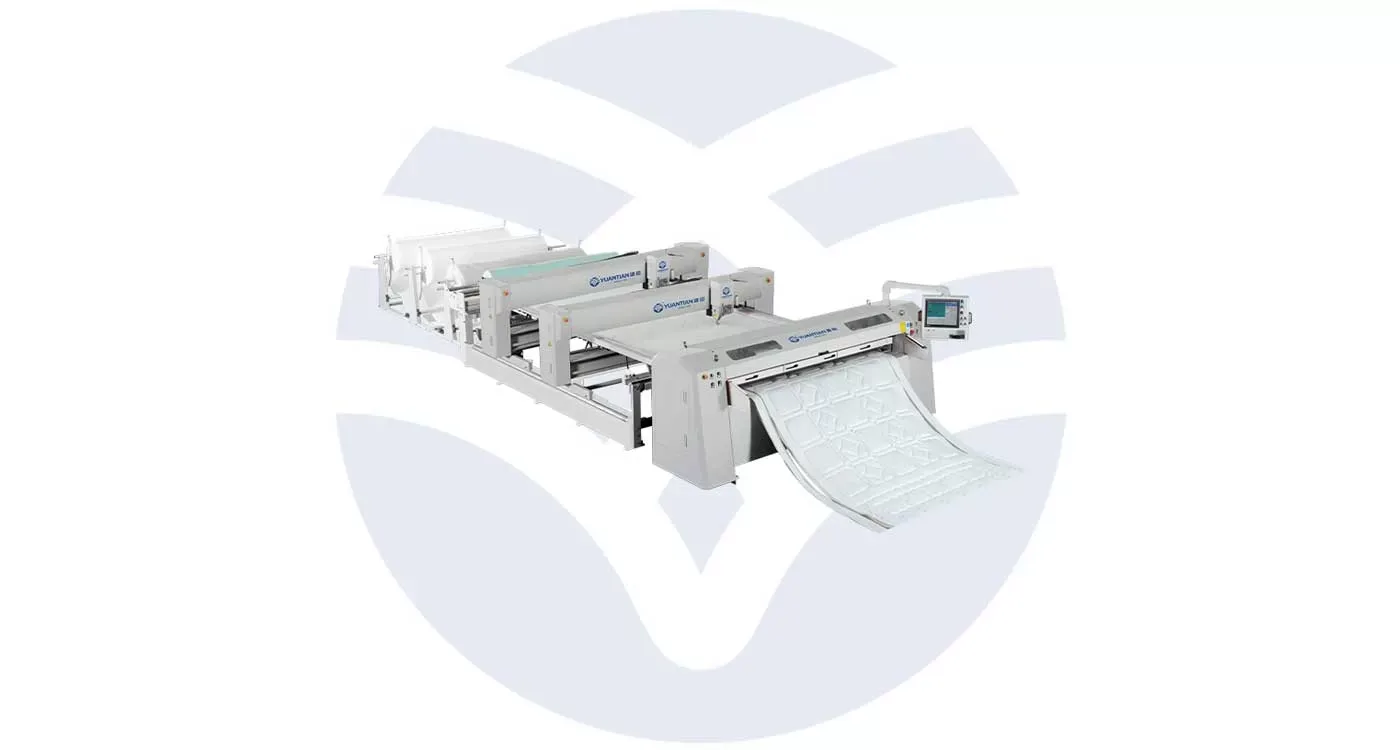

Mattress quilting machines are devices applied in the mattress manufacturing process for both functionality and aesthetic value. They stitch the layers of fabric and padding that form the quilted surface of the mattress, this adds to the comfort and fine details of the mattress.

Understanding the different types of quilting machines, their components, and operational principles is very critical for any manufacturer seeking to have an optimized production process and to produce high-quality mattresses. This guide takes an in-depth look at the basics of mattress quilting machines.

Types of Mattress Quilting Machines

Multi-Needle Quilting Machines

This is a multi-needle quilting machine designed for high-volume production and stitching complex patterns effectively. These machines have more than one working needle, therefore, they would ideally work in big and high-scale manufacturing.

Features and Benefits

- High Efficiency: The multi-needle machines can produce the intricate quilting pattern quickly, therefore, increasing the speed of production.

- Consistent Quality: The multiple needles will guarantee uniform stitching, thus providing consistent quality products.

- Versatility: These machines are capable of processing a wide variety of fabrics and padding materials for various mattresses.

Single-Needle Quilting Machines

Single-needle quilting machines are the most preferred because of their versatility and preciseness, they are used to make most of the high-end and specialty mattresses. These quilting machines use a single needle to outline details and intricate patterns of design.

Features and Benefits

- Design Flexibility: Much more control of the quilting pattern allows for producing individual designs of great intricacy.

- High Precision: These machines offer precise stitching, which is crucial for high-quality, customized mattresses.

- Lower Speed: Though they operate at a lower speed compared to multi-needle machines, the emphasis is on quality and customization rather than quantity.

Computerized Quilting Machines

Advanced computers are integrated into a quilting machine to provide automation of the quilting process and thus highly improve efficiency and accuracy.

Features and Benefits

- Automation: Most of the functions in the quilting process are made automatic by these computerized machines.

- High Precision: They provide extremely accurate stitching by computer-controlled operation.

- Pattern Storage: They have huge storage that contains a huge bank of different patterns regarding quilting, which can be changed and customized quickly.

Core Components of Quilting Machines

Needle and Hook Assembly

The quilting machine’s heartbeat is its needle and hook assembly, responsible for the actual stitching.

Needle Types

The type of fabric and padding materials call for different types of needles. The right kind of needles set the premise of perfect stitching.

- Ballpoint Needles: Good for knit fabrics since they will not snag.

- Sharp Needles: Sharp needles stitch cleanly and with sharp points in woven fabrics.

Hook Mechanism

The hook mechanism cooperates with the needle and forms stitches. A good hook mechanism will ensure fluent and reliable stitching.

Fabric and Padding Feed System

The feed system moves the layers of fabric and padding under the machine and its sight, ensuring correct alignment for the stitches.

Rollers and Feed Dogs

The rollers and feed dogs hold and guide the layers of fabric, applying even tension and avoiding slippage.

- Adjustable Rollers: Provide fine control of fabric tension.

- Feed Dog Settings: There are different feed dog settings available for various thicknesses of fabric. These settings ensure smooth feeding without any problems.

Frame and Clamping System

The frame, with the help of a clamping system, firmly holds the fabric and padding in place during the quilting process to ensure accurate stitching.

Control Panel and Software

Advanced quilting machines boast state-of-the-art control panels and software that bring everything to the fingertips of the operator during the quilting process.

User Interface

The user interface allows operators to set and adjust machine parameters, select quilting patterns, and monitor the machine’s performance.

- Touchscreen Interfaces: Enhance usability and offer intuitive controls.

- Pattern Selection: Easy selection and adjustment of quilting patterns.

Software Integration

Advanced software integration enables computerized quilting machines to offer high precision and automation.

- Pattern Design Software: Allows for the creation and modification of quilting patterns.

- Machine Monitoring: Provides real-time data on machine performance and diagnostics.

Operational Principles of Quilting Machines

Stitch Formation

A very critical aspect of quilting machines is the process of stitch formation. Without an understanding of the process, the whole exercise of handling these machines may prove futile.

Lockstitch Mechanism

Mostly, the quilting machines work based on a lockstitch mechanism, whereby the thread from the needle interlocks with the thread on the spool to provide maximum security for the stitch.

- Penetration of the Needle: The needle penetrates the fabric carrying the thread through.

- Capture by the Hook: The hook captures the thread of the needle and intertwines it with the thread on the spool.

Stitch Length and Tension

The ability to change stitch length and tension is crucial for the development of a quilting pattern and also for preventing the ruin of fabric.

- Stitch Length Control: This denotes the space between stitches, which changes the density of a pattern.

- Thread Tension Adjustment: It manages the balance between needle and bobbin thread tension to prevent puckering or loose stitches on the fabric.

Fabric Handling and Movement

The way you handle and move your fabric is very important to keep your quilting accurate and in one piece.

Synchronized Feed System

A synchronized feed system means the top and bottom layers of fabric move as one, with no shifting or misalignment.

- Top Feed: Guides top layer of fabric.

- Bottom Feed: Moves the bottom layer of fabric in unison with the top feed.

Speed Control

Speed control settings enable the operator to adjust the speed of operation of the machine based on the type of fabric being used and the complexity of the quilting pattern.

- Variable Speed Settings: Provide flexibility with various speeds for different materials and patterns.

- High-Speed Operation: Increases production efficiency for simpler patterns.

Conclusion

Mattress quilting machines are quite important in the manufacture of quality mattresses, both adding strength and beauty to a mattress. The knowledge of the various types of machines, their parts, and their operational principles helps manufacturers make informed decisions and thus optimize their production.

High-quality quilting machines with proper care and maintenance will help in producing continuous quality products, increasing speed in production, and saving money in the long run. Upgrades to quilting machines will continue to keep mattress manufacturers in business and competitive within the changing market.

Связанные с ними товары