- Home » Troubleshooting Common Mattress Tape Edge Machine Issues

Mattress tape edge machines are essential in the production of mattresses, where they sew the edges to create a neat and durable finish. Like any piece of industrial equipment, these machines can encounter issues that disrupt production and affect the quality of the finished product.

Understanding common problems and their solutions is crucial for maintaining efficiency and ensuring high-quality output. Here’s a comprehensive guide to troubleshooting common issues with mattress tape edge machines.

Understanding the Mattress Tape Edge Machine

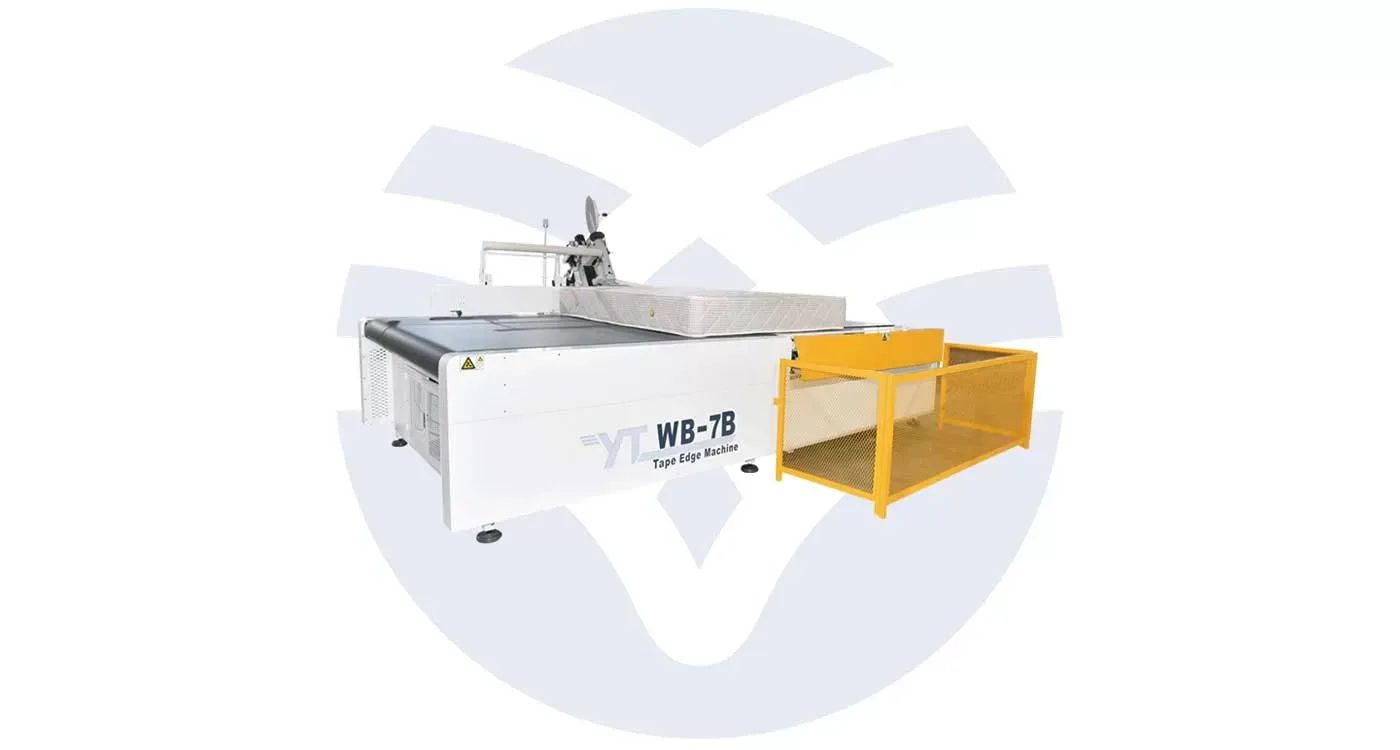

Before any troubleshooting is done, a basic understanding of the components and how the mattress tape edge machine works is relevant. It typically comprises a sewing head, feed mechanisms, tape dispenser, and conveyor or rotating table.

The mattress will be fed through the machine, which applies tapes along its edges by means of a sewing head to strengthen them at the edges and finish them. This requires exact coordination between feed, sewing, and tape application systems.

Common Issues and Troubleshooting Tips

1. Thread Breakage

Symptoms: The thread breaks frequently during operation.

Causes and Solutions:

– Incorrect Thread Tension: Check the thread tension and adjust it if necessary. Too much tension will break the thread; too little will produce loose stitches.

– Worn or Damaged Needle: Check the needle for signs of wear or damage. Replace the needle if bent, dull, or with burrs on it.

– Poor Quality Thread: Use good quality thread compatible with the type of material being sewn. Low-quality threads are prone to breakage easily.

– Thread Path Obstructions: Follow the travel path of a thread to check for obstruction or snagging of the thread. The thread should pass freely through all guides and tension disks.

2. Skipped Stitches

Symptoms: The machine occasionally skips stitches, resulting in incomplete or weak seams.

Causes and Solutions:

– Needle Issues: Always use the appropriate type and size of the needle for the material and thread. A bent or otherwise unsatisfactory needle can lead to skipped stitches.

– Timing Problems: The timing between the needle and the hook could be off. Adjust the timing following the manufacturer’s directions or seek a technician to do it properly.

– Improper Fabric Feeding: Be ensured that the fabric feeds uniformly, and any lopsidedness is avoided. If the fabric is not feeding smoothly and regularly under the needle, skipped stitches may then occur.

3. Fabric Jamming

Symptoms: The fabric gets stuck or bunches up under the needle, causing jams.

Causes and Solutions:

– Feed Dog Issues: The feed dogs—those teeth that pull the fabric through the machine—should be checked for cleanliness and proper working alignment. Their height may also need adjustment if required.

– Incorrect Presser Foot Pressure: The fabric may jam due to too much or too little force from the presser foot. Adjust the pressure so that the pieces feed smoothly.

– Obstructions: Make sure that there is no fabric path rubbish, such as blockages, and that leading edges are not being pulled at an angle.

4. Inconsistent Stitch Length

Symptoms: The length of the stitches varies, leading to an uneven appearance.

Causes and Solutions:

– Feed Dog Problems: Check feed dogs for wear or misadjustment. Be sure they feed fabric along in a uniform manner.

– Tension Issues: Check both upper and lower thread tensions. The inconsistent tension causes swaying stitches.

– Mechanical Wear: Due to certain continuous usage, mechanical parts like the feed mechanism are worn out. This can be avoided by regular servicing and oiling. Replace worn parts with new ones.

5. Tape Misalignment

Symptoms: The tape is not being applied evenly along the edge of the mattress.

Causes and Solutions:

– Tape Guide Adjustment: Ensure that the tape guide is adjusted properly and aligned to the sewing path. Otherwise, this might cause uneven laying of tapes.

– Consistent Fabric Feeding: If the mattress is fed unequally, this may cause misaligned tape. Check if the feeding system runs smoothly and constantly.

– Tape Tension: Check the tape tension to the roll. The high tension of the tape shall result in tape stretch and misplacement, while the low tension of the tape would give slack for tape laying unevenly.

6. Needle Breakage

Symptoms: The needle breaks frequently during operation.

Causes and Solutions:

– Incorrect Needle Size or Type: Use the correct type of needle, regarding size, for the fabric and thread. Refer to the machine manual for recommendations on suitable needles for the machine.

– Improper Installation: The key thing here is the proper installation of the needle and its tightening. If the needle remains loose due to improper installation, it will break.

– Material Issues: The fabric may have some hard or dense settings which are the cause of the breakage of the needle. Adjust the sewing speed accordingly.

7. Machine Noise

Symptoms: The machine makes unusual noise or more noise than usual while running.

Causes and Solutions:

– Inadequate Lubrication: Apply lubrication following the recommendations of the manufacturer. The absence of lubrication would result in friction, which naturally generates noise.

– Loose Parts: Checking the machine for loose screws or other parts that may integrate with it. Tightening the loose parts so as to reduce the noise and damage.

– Worn Parts: With time, the parts become worn out, which leads to noise. Regular checks on the wear and tear of parts and replacing them whenever necessary.

8. Electrical Issues

Symptoms: Power fluctuation in the machine or some of its functions not working.

Causes and Solution:

– Power Supply: Plug the Machine into a stable power supply; Check for loose/damaged power cords.

– Internal Wiring: Check the internal wiring of the machine for any wear or damage and change any faulty wiring.

– Control Panel Malfunctions: The control panel may either be reset or repaired in this case. One can refer to the manual of the machine or seek professional help.

Preventive Maintenance Tips

Most of the issues mentioned above can be easily prevented by exercising preventive maintenance. In addition, preventive maintenance also increases the life span of your mattress tape edge machine. Here are some tips for that:

Regular Cleaning: Clean out the machine from all dust, lint, and fabric debris after every use. This holds specifically for the sewing head, feed dogs, and the thread path.

Scheduled Lubrication: Use oil in appropriate and regular intervals for moving parts as advised by the manufacturer. This reduces friction and hence consequential wear.

Routine Inspections: Each component of the sewing machine should be open to routine inspection. Check all components for signs of wear and damage, misalignment, and correct them immediately.

Operator Training: Ensure all operators are trained in the operation and maintenance of the machine. Well-trained operators are likely to cause less damage and are more likely to identify problems early.

Use Quality Materials: Use good thread, needles, and tape that is made to run on your specific machine, as well as with the kind of materials being used. Low-quality materials may be the cause of frequent problems.

Documentation: all types of maintenance activities, repairs, and replacement of parts carried out on the tape edge machine shall be fully documented. Documentation keeps track of the condition of the machine and provides for proper planning of future maintenance activities.

Conclusion

A mattress tape edge machine is a critical tool in mattress manufacturing, and keeping it in optimal condition is essential for maintaining production efficiency and product quality.

By understanding common issues such as thread breakage, skipped stitches, fabric jamming, inconsistent stitch length, tape misalignment, needle breakage, machine noise, and electrical problems, and by implementing preventive maintenance practices, manufacturers can ensure smooth operation and longevity of their machines.

Regular maintenance, proper operator training, and the use of quality materials are key to preventing issues and minimizing downtime, ultimately leading to the production of high-quality mattresses.

Связанные с ними товары