- Home » Top Features to Look for in a Mattress Flanging Machine

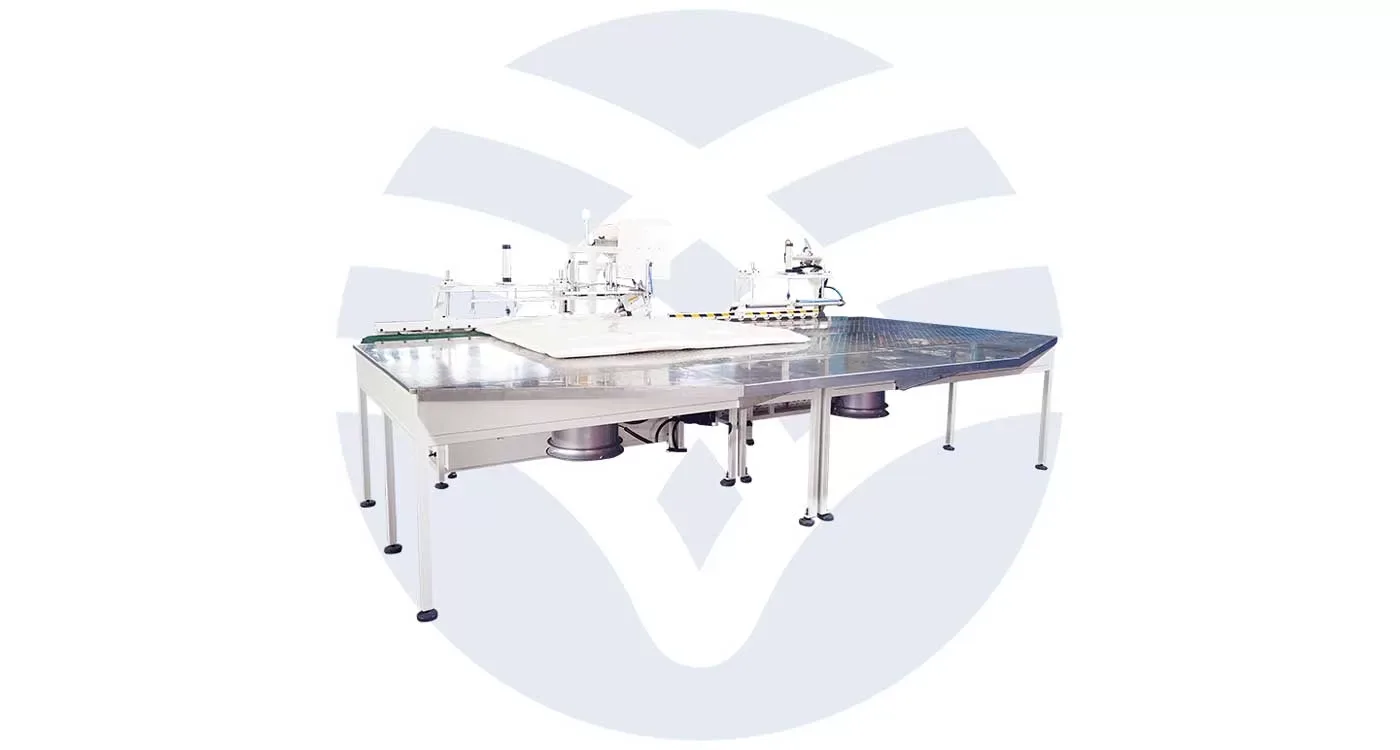

The mattress manufacturing industry requires much precision, efficiency, and durability. A mattress flanging machine is one of the major pieces of equipment involved in the process. This specialized machine is used to attach the flange—an attached fabric border—to the edges of mattress panels, which happens to be one of the most critical steps in the making of mattresses.

Choosing the proper flanging machine can make a huge difference in the quality and production efficiency of your mattresses. Here are some top features that you must look for while choosing a mattress flanging machine:

Build Quality and Durability

The build quality forms the crux of any mattress flanging machine. It is obvious that the continuous high-intensity usage the machines go through entails them being strong and long-lasting. Look for high-quality materials of construction, like stainless steel and heavy-duty aluminum.

Bearings, gears, and other components, including the sewing head, have to be designed for a long life with very little maintenance. A sturdy machine cuts downtime and assures continuous performance over some time.

Precision and Accuracy

Accuracy is everything when producing mattresses. The flanging machine should be capable of aligning the flange with the mattress panel edges to create consistency and a professional appearance.

More advanced machines have computerized controls and sensors for increased accuracy. Main features such as automatic edge guiding systems or programmable settings also help in maintaining accuracy, thereby reducing the possibility of human error and increasing quality.

Speed and Efficiency

High speed is required in any competitive market. High-speed flanging machines help increase productivity dramatically. To avoid detriment to the quality of the products, ensure that the speed comes with adjustable settings that allow the operator to fine-tune the performance according to material and finish requirements.

Quick-change systems that provide fast switching between a variety of flange types and sizes with minimal downtime are just a few of the hallmarks of more efficient machines.

Ease of Use and Ergonomics

The ease and comfort of operators go in tandem with productivity and low fatigue. Better, ergonomically designed machines with more intuitive controls create more efficient operators.

Touch-screen interfaces, adjustable work tables, and easy-to-use software make the machine more operable and reduce the learning curve of new operators. Automatic threading and self-lubrication of parts make handling and operation of the machine much easier.

Versatility

Such a versatile flanging machine, therefore, can be used on various materials and flange types to help the manufacturer produce a myriad of mattress designs. Seek adjustable settings for stitch length, flange width, and tension control in the flanging machine.

Some high-end machines have interchangeable modular components that can be changed quickly for different production applications. This flexibility is valuable for manufacturers looking to innovate and offer customized products.

Stitch Quality

The overall quality of the mattress is determined by that of the stitch. A flanging machine should give consistent, tight, and clean stitches and not easily come undone. Features like automatic tension control, programmable stitch patterns, and quality needles all contribute to better stitch quality.

Machines offering a number of stitches in a range will enable the manufacturer to create different aesthetic and functional results to suit different tastes of customers.

Automation and Advanced Features

Automation can significantly enhance productivity and consistency. Most of the new flanging machines come with advanced features like auto edge trimming, thread cut, and programmable stitching patterns.

All these features reduce manual intervention and increase speed in production with minimal errors. Some have IoT capabilities that enable remote monitoring and diagnostics, further streamlining operations to reduce downtime.

Safety Features

Safety is one thing that should not be taken lightly. Check for machines that have adequate safety features such as emergency stop buttons, protective guards, and malfunction detecting sensors. These protect operators against mishaps, ensuring safer working conditions.

Additionally, machines that comply with industry safety standards and regulations can help manufacturers avoid legal issues and potential liabilities.

Energy Efficiency

Energy efficiency is an important consideration for reducing costs and saving the environment. Flanging machines that come with advanced motor technology have optimized power consumption, thus becoming energy-efficient.

Look for machines that come with energy-saving modes and low-rated power consumption. Energy-efficient machines will help reduce operational costs but minimize the carbon footprint alongside the principles of sustainable manufacturing.

Maintenance and Support

Regular maintenance can help to keep the machine in good working order and extend its service life. A flanging machine from a reputable manufacturer who can also provide adequate support in terms of training, maintenance services, and easily available spare parts might make all the difference.

Machines designed for ease of maintenance, in which components are accessible and instructions are clear, reduce downtime, thereby cutting the costs for maintenance. Good after-sales support ensures that any problems can be rectified in the shortest possible time, thus minimizing disruption to production.

Cost and Return on Investment (ROI)

Although a mattress flanging machine represents an initial huge cost, it is necessary to gauge the worth or value of the machine in general and its payback. Probably, a high-quality and efficient machine may cost much up front, but in the long term, it will help save through improved productivity and reduced maintenance cost with lesser downtime. Consider the total cost of ownership, the energy consumption, maintenance, and possible savings from better efficiency and quality.

Conclusion

Investing in a high-quality mattress flanging machine is crucial for any mattress manufacturer aiming to produce superior products efficiently. By considering factors such as build quality, precision, speed, ease of use, versatility, stitch quality, automation, safety, energy efficiency, maintenance, and overall cost, manufacturers can select a machine that meets their specific needs and enhances their production capabilities.

A well-chosen flanging machine not only improves the manufacturing process but also contributes to the overall success and competitiveness of the business.

Связанные с ними товары