- Home » The Role of Quilting Machines in Mattress Quality Control

Quality control in mattress manufacturing is crucial for ensuring that the final product meets the expectations of consumers and adheres to industry standards. Since quilting machines stitch these layers of fabric and padding together to form the top layer of a mattress, their role in quality control is crucial.

These machines influence the mattress’s aesthetic appeal and contribute significantly to its structural integrity and comfort. This passage explores how quilting machines impact mattress quality control, focusing on their design, operation, and integration into the broader manufacturing process.

The Importance of Quality Control in Mattress Manufacturing

Ensuring Consumer Satisfaction

Quality control is a very important process that a mattress manufacturing plant needs to subject its products to if it wants its mattresses to meet high consumer expectations. A mattress represents an investment in a person’s comfort for years to come, so construction deficiencies can result in discomfort and reduced longevity, producing dissatisfied consumers.

One of the final processes of assembling a mattress, quilting is very important to get a finished product that looks great and feels comfortable. For manufacturers, a well-running quilting machine offers consistency and quality, translating into greater consumer satisfaction and brand loyalty.

Adhering to Industry Standards

There are various standards and regulations set for the mattress-making industry that any manufacturer is mandated to be in a position to meet. Such aspects include flammability, durability, and material safety standards.

Quilting machines help the manufacturer attain these standards by stitching, which is precise, the materials are firmly bonded, and the overall construction of the mattress is robust. It not only contributes to compliance with such laws but also protects a manufacturer’s reputation and reduces the risk of product recalls.

The Functionality of Quilting Machines

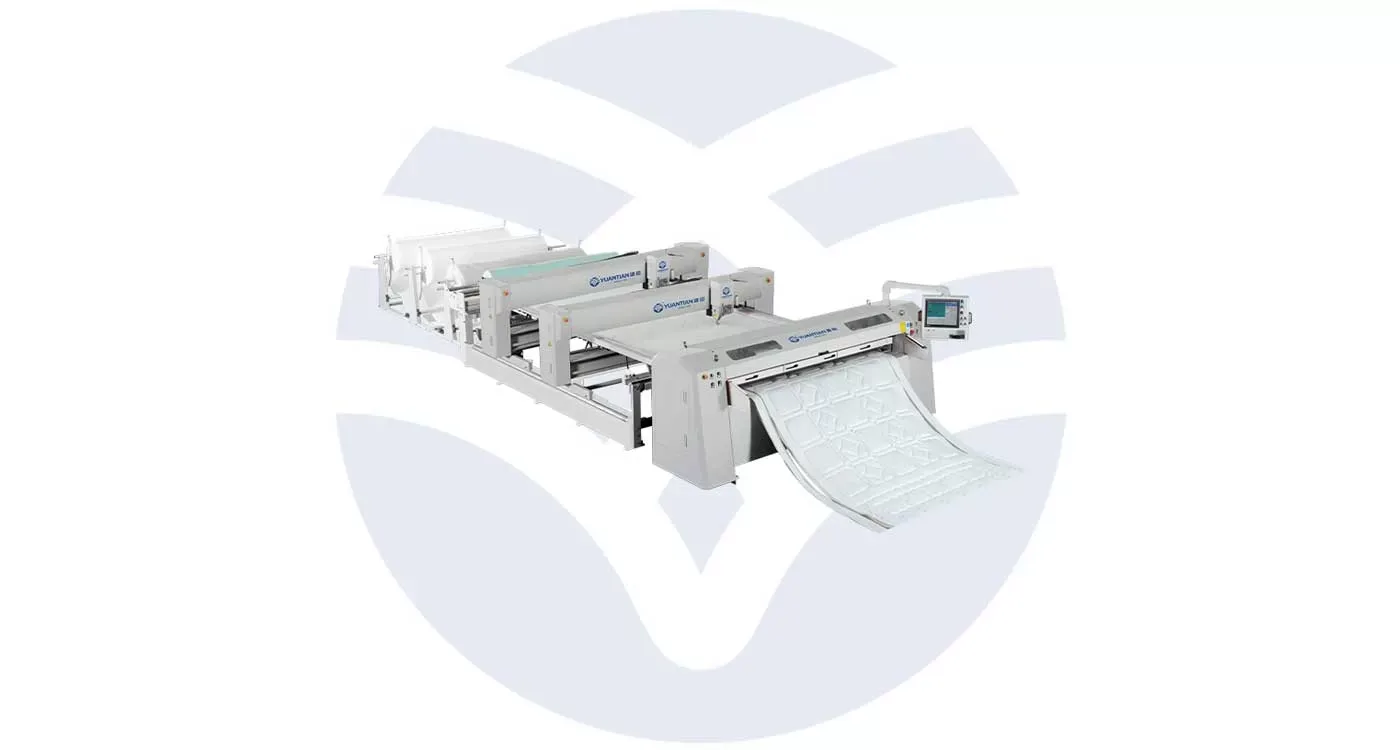

Types of Quilting Machines Used in Mattress Manufacturing

There are several types of quilting machines used in mattress manufacturing. Some of these quilting machines come with specific capabilities or advantages. Some of the common ones include:

Single-Needle Quilting Machines: They have a single needle that sews the layers of the fabric together. Primarily, these are used for complex designs and patterns on the mattress surface.

Multi-Needle Quilting Machines: This category of quilting machines has a number of needles that simultaneously quilt large sections of fabric. It increases line speed and, hence, productivity in the overall mattress manufacturing process. They are mainly used for simple, repetitive patterns.

Computerized Quilting Machines: Equipped with advanced software, these machines can produce complex patterns with high precision. They allow for greater customization and consistency in quilting designs.

The Quilting Process

Quilting is when the layers of fabric and padding included in the mattress construction are stitched together. The materials are fed through the needles of the quilting machine, which sew them together in a pattern according to the desired design.

This stitching not only adds to the cosmetic appeal of the mattress but also makes the mattress structurally sound by holding the layers in place and preventing them from shifting or bunching over time. The quality of the stitching, including its uniformity, tension, and durability, is critical to the overall quality of the mattress.

The Impact of Quilting on Mattress Quality

Enhancing Mattress Aesthetics

Perhaps the most common function of quilting within mattress manufacturing is to improve the looks of the product. These patterns could be very basic, serving purely functional purposes, or they may be highly ornate and decorative, depending on the aims of the brand.

Not only does this provide visual interest, but it is a talking point for the identity of a brand and its level of detail. High-quality quilting can set a mattress apart in today’s crowded marketplace by drawing in consumers who want both functionality and beauty in their bedding products.

Contributing to Structural Integrity

Quilting does much more than add beauty. The stitching holds the mattress’ layers together and prevents their even distribution within the mattress, thereby preventing their movement when the mattress is in use. This makes it very important to ensure comfort and support in a mattress throughout its lifetime.

Poor-quality quilting can simulate problems such as uneven surfaces, lumpiness, and reduced durability, hence giving the user less-than-desired experience and product life.

Improving Comfort and Support

Quilting may also be used to improve the comfort and support a mattress provides. The stitching creates zones, differing in the pressure or support exerted on different body areas. For instance, the middle would be more firmly quilted to have better lumbar support, and the edges would be softly quilted to make it more comfortable. This zoning in quilting may further enhance the sleeping experience with stronger support where needed.

Integrating Quilting Machines into the Quality Control Process

Monitoring Stitching Consistency

In quality control, uniformity is very important, which means that a stitching machine must be capable of delivering consistent stitching across all mattress surfaces. Any inconsistency of stitch length, tension, or pattern will visibly affect the visible appearance and performance.

Sensors and computer controls in advanced quilting machines are programmable to read these variables at all times, enabling the machine to make each stitch consistent with what the manufacturer has specified. Calibration of the machine and regular maintenance are also necessary to maintain this consistency.

Detecting and Correcting Flaws

Quilting machines are proactive, they detect faults and rectify them right at the manufacturing stage. The automated systems can detect the fault, be it a skipped stitch, thread breakage, or misaligned fabric, and stop the production process until the fault is rectified.

This kind of control reduces the possibility of faulty products reaching consumers. It also saves wastage from the detection of errors at the start of the production line.

Documenting Quality Metrics

It is also possible for modern quilting machines to document quality metrics on the number of stitches per inch, accuracy of patterns made, and material used. This information is most important for quality control because it keeps the quality control team fully apprised of the mattress production history of the mattresses manufactured by that line of production.

In the line of quality issues, these records will help in retracing the origin of the problem, probably some machine setting, material flaw, or operator error. This traceability is critical to a continuous improvement drive for maintaining high standards in mattress making.

Innovations in Quilting Technology for Quality Control

Smart Quilting Machines

Probably one of the most alive ways in which innovative improvements to quality control have altered quilting machines forever is in the level of integration of smart technology. Such quilting machines can, for example, be connected to the IoT, thus enabling remote monitoring and diagnostics.

Smart quilting machines would have more intelligence built into them and make adjustments to machine settings based on analysis of the production data for future optimal runs. The degree of intelligence at its foundation helps manufacturers sustain quality consistency and fast-track changes emerging in production needs.

Sustainable Quilting Practices

With the progression of the industry towards more sustainable practices, quilting machines are evolving to support eco-friendly production. The functions of the machines are such that there is less wastage, they use less energy and also use better materials that are sustainable.

In addition, this is critical in not only minimizing the impact on the environment because of mattress manufacturing but also contributing towards product quality as a result of better inclusion of sustainable materials that hold mattresses in better quality and comfort.

Enhanced Automation and Robotics

Notably, the automation of quilting machines is getting sophisticated, it is playing an increasingly important role with robots. Tasks requiring high precision and repetition are done by robots at a much faster rate, with accuracy higher than what human operators can achieve.

For this reason, robotics in quilting ensures that every mattress being made meets the exact specifications, further solidifying the quality control and consistency of this manufacturing process.

The Future of Quilting Machines in Quality Control

Continuous Improvement and Adaptation

Quilting machines in mattress manufacturing will be integrated with advanced technologies like artificial intelligence, machine learning, and real-time data analytics in the future. These innovations will allow manufacturers to constantly improve product quality and quickly adapt to changes in consumer demand and evolving industry standards.

Customization and Flexibility

With increased consumer demand, more flexibility with regard to design and production will be expected of quilting machines. In the future, quilting machines may incorporate variable settings so that different patterns and materials can be used quickly. All this flexibility will allow manufacturers to meet diverse consumer needs without compromising on quality control.

Conclusion

Quilting machines, in terms of quality control with mattress manufacturing, make an impact on the aesthetic, structural, comfort, and durability aspects of a mattress.

As technology continues to advance, these machines are becoming even more integral to ensuring that mattresses meet the high standards expected by consumers and industry regulators. Through a combination of advanced machinery, skilled operators, and rigorous quality control processes, the future of quilting in mattress manufacturing promises to deliver products of exceptional quality and reliability.

Связанные с ними товары