- Home » The Role of Mattress Tape Edge Machines in Quality Assurance

Mattress manufacturing is a meticulous process that requires precision, skill, and the right equipment to deliver high-quality products. Among the essential machines in the production of mattresses is the mattress tape edge machine. This machine plays a critical role in ensuring the durability, aesthetics, and overall quality of the final product.

In this article, we will explore the importance of mattress tape edge machines in quality assurance, focusing on their role in enhancing mattress integrity, the different types of tape edge machines, and the features to consider when selecting the right machine for optimal results.

The Importance of Mattress Tape Edge Machines

Ensuring Mattress Integrity

The tape edge process is of major essence in the durability of a mattress. It consists of the top and bottom panels of the mattress being attached to the border panel with a strip of fabric tape. This step not only gives the mattress a clean, finished look but also reinforces its structure.

A well-attached tape edge keeps the layers inside the mattress from coming apart, thus, the foam, springs, or any other element within does not shift out of place or detach over time. This structural integrity directly affects the life and comfort of the mattress, which are two of the quality indicators.

On the other hand, an improperly finished edge will start showing wear and tear rather quickly, thereby making customers less satisfied with the product. This may result in returns or warranty claims, and mattress tape edge machines come in handy because they ensure consistent, durable seams that definitely enhance the ability of the mattress to last for years with heavy use.

Enhancing Aesthetic Appeal

Besides just functionality, the aesthetic appeal of the mattress depends somewhat on the tape edge. Most consumers would judge the quality of a mattress through its outward look before they lie on it. A mattress with poorly stitched edges-with uneven stitching or loose fabric-could give a negative first impression, no matter how well the inner components of the bed are designed.

The edge tape also makes the mattress look neat and professional, hence adding attractiveness to its looks, especially helpful for the manufacturer in creating an outstanding product in the competitive market. The adoption of good-quality fabric tape along with precision stitching may also enable the manufacturer to add the branding element or some special unique touch to the design, thus making the product furthermore attractive.

Improving Manufacturing Efficiency

The other key benefit, besides ensuring quality, is the efficiency provided during production by mattress tape edge machines. Conventionally, sewing tape edges by hand are generally very inconsistent and time-consuming, with a high count of human error.

Special machines automate the process with higher production speeds and consistent stitching with minimal defects. This efficiency not only cuts down on production costs but also enables manufacturers to meet tight deadlines without compromising on quality. It becomes critical to retain brand reputation and customer trust with the ability to make a large volume of mattresses with consistent quality.

Types of Mattress Tape Edge Machines

Manual Tape Edge Machines

Smaller manufacturers and those in the business of making mattresses on customized orders may use manual tape edge machines. In operation, the operator guides the mattress through the machine, which stitches the tape to the edge. While allowing for highly controlled usage, these machines are quite a bit slower and more labor-intensive compared to their automated brothers.

In such specific niches where personalization and skill are the most important features, manual machines can be of great help. They allow operators to change the settings right in the process according to the specific design or type of mattresses that need particular attention.

Semi-Automatic Tape Edge Machines

Semi-automatic tape edge machines fall between purely manual machines and automation. It would include all the above machines with automated stitching, while the operator still controls the mattress. Such a setup makes this highly accurate and quicker than any manual model, yet still retains some operator involvement with difficult designs or material variations.

These machines work well for medium-sized manufacturer who needs to have some flexibility in their production while maintaining a high output.

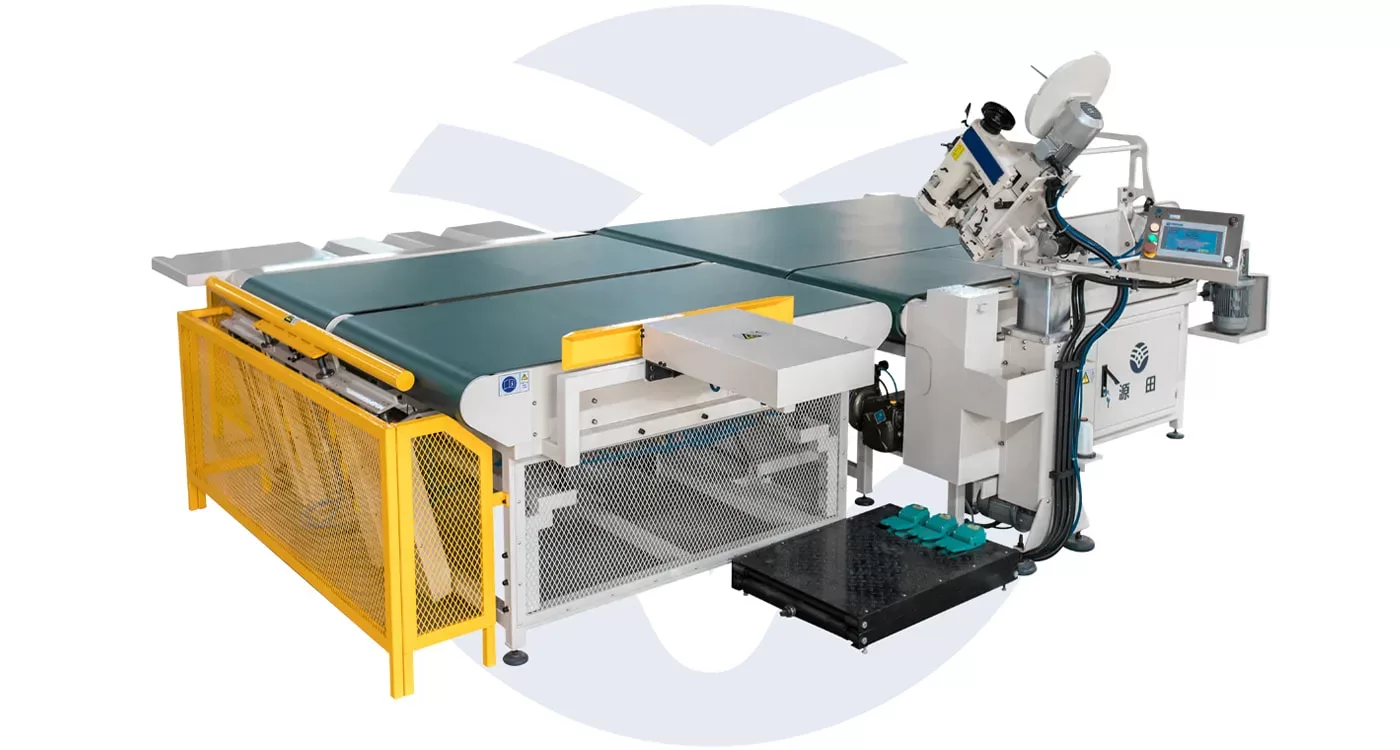

Fully Automatic Tape Edge Machines

Fully automatic tape edge machines are the most advanced and efficient option for large-scale mattress manufacturers. They can completely automate the sewing of the tape onto the edge of the mattress. The mattress is automatically fed into the machine, where the tape is stitched along the edges with consistent tension and stitching.

Equipped with programmable controls and sensors, the full automata machine ensures that every mattress produced will have even quality to minimize or eliminate errors. They are suitable for those manufacturers whose demand for volume is high and have strict control over the quality.

Features to Consider in a Mattress Tape Edge Machine

Stitching Precision and Quality

The most essential aspect of any tape edge machine is stitching. Stitching should be accurate and equally dispersed so that the edges of a mattress are well-attached. Those machines with stitch length and tension adjustment allow factories to adjust stitch conditions according to mattress types, like mattresses with thicker padding or different fabric material.

Besides, the versatility of a machine to work with different types of threads and fabric tapes contributes to greater variability and flexibility in the manufacturing process.

Speed and Automation

The speed of production will, therefore, be an important consideration for such manufacturers who want efficiency. The more automation on such a machine, the faster the work it can present consistently. However, the balance must be created, this is because a machine that prioritizes speed without consideration for creating durable seams only leads to defects and lowers the overall quality of the mattress.

The fact that multi-speed programmable machines allow the operator to adjust according to the complexity of the design and the type of mattress material used is also quite beneficial.

Durability and Maintenance

A good mattress tape edge machine should be solid and built to last under the rigors of non-stop production. Machines made of robust materials in which their parts are resistant to wear and tear will go a long way toward longevity and infrequent breakdowns.

Maintenance is another important consideration that can be undertaken to increase the life span of the machine. Most modern machines have self-lubricating mechanisms and easy access panels for quick checks. Low maintenance, coupled with long-life reliability, can save a lot of money over time.

Flexibility for Different Mattress Sizes and Materials

The manufacturing of mattress tape edges involves making different products. This can range from the making of standard sizes to various custom orders that involve different materials. The best tape edge machines can have mattresses in a number of different sizes and thicknesses. For example, adjustable tables offer the easiest movement of mattresses of different dimensions by the operator to ensure stitches are equal and correct on all products.

A machine that can be universally used for various materials of mattresses is highly flexible, like switching from foam to latex or innerspring mattresses. This makes such machines ideal for those manufacturers that offer a wide product range.

Conclusion

In the competitive mattress industry, mattress tape edge machines are indispensable for ensuring the quality, durability, and appearance of the final product. Whether manual, semi-automatic, or fully automatic, these machines provide manufacturers with the tools to create mattresses that not only meet but exceed customer expectations. From enhancing structural integrity to improving manufacturing efficiency, these machines play a crucial role in every step of the production process.

Связанные с ними товары