- Home » The Role of Decorative Border Machines in Mattress Production

In the world of mattress manufacturing, innovation and efficiency are critical to ensuring high-quality products that meet consumer demands. Among the many advancements in this field, decorative border machines have played an integral role in transforming how mattresses are produced.

These machines, designed specifically for creating detailed and aesthetically pleasing borders on mattresses, serve both functional and decorative purposes. This article explores the significance of decorative border machines in mattress production, diving into their history, technical capabilities, benefits, and their future role in the industry.

The Evolution of Decorative Border Machines

A Brief History of Mattress Manufacturing

Mattress production has largely evolved from its early roots. In ancient times, mattresses were a product of natural materials such as straw, animal hides, or wool, which were then stuffed into bags. As times changed, the manufacturing became more technical with additions of springs, foam, and fabric coverings to the mattresses. While mattresses continued to improve both in design and functionality, manufacturers started pursuing ways of improving not only their comfort and durability but also their aesthetic appeal.

It was not until well into the late 20th and early 21st century that the industrial revolution, which had begun introducing mass production to bedding manufacture as early as the 19th century, was to include border-making machines as an integrated and common part of the manufacturing process. Such machines allowed for an iconic border with great detail, apt to enhance the mattress for aesthetic purposes, while at the same time, being a useful marketing tool in terms of setting brands and models apart.

The Introduction of Decorative Border Technology

The introduction of decorative border technology revolutionized mattress design and manufacturing. Previously, the edges of mattresses were just about plain and never a prime focus in manufacturing. It is for this reason that the prime focus of mattress production was on the core layers-springs and foam, among others.

However, with the increasing demand from consumers for products that combine comfort and aesthetics, the role of the mattress border became leading. Manufacturers sought ways of branding, patterning, and giving other embellishments to the mattress, that is how decorative border machines came into existence.

How Decorative Border Machines Work

Basic Functionality

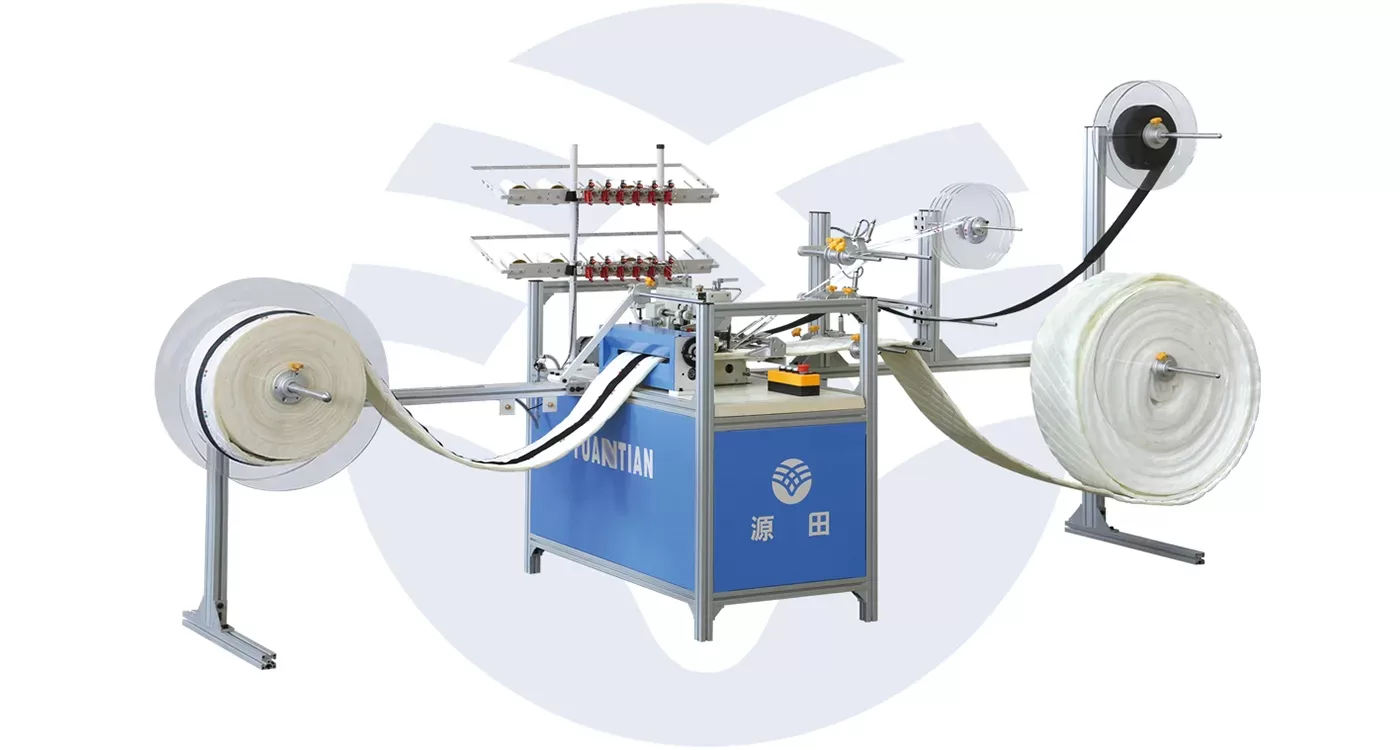

Decorative border machines are special machines that stitch and decorate the edges or borders of mattresses. These can make several patterns, logos, and designs serving both functional reinforcement and aesthetic detailing of the mattress edge.

Among these, the average border machine will have advanced features such as high speeds for stitching, programmable designs, and settings to adjust to the many types of materials and threads. Operation The machine works by feeding the border material, mostly being a heavy-duty fabric, through its mechanisms while the computer-controlled system creates an intricate stitching pattern down the length of the fabric.

Automation and Precision

Among the largest advantages of modern decorative border machines are their level of automation and precision. Pre-designed patterns can be uploaded through specialized software, or they can be used to create new ones, giving great latitude to the user. Once designed, the machine will execute that design with pinpoint accuracy, allowing consistency in all mattresses produced.

With such a level of automation, it drastically cuts down on the margin for human error while increasing production rates significantly at the same time. This enables manufacturers to meet the quotas of higher production without ever having to sacrifice quality. Additionally, automation allows many different designs with minimal interference from workers, hence enabling companies to manufacture several lines of mattresses, or even custom orders for individual customers, with so much more ease.

Benefits of Using Decorative Border Machines in Mattress Production

Enhanced Aesthetic Appeal

One of the chief benefits of ornamental border machines is the capability they afford to create mattresses that are a feast for the eyes. Oftentimes, the borders of a mattress are among the first things that consumer notices as they go about selecting a bed. A well-stitched border, with fanciful designs, branding, or even custom patterns, hints at luxury and craftsmanship. This aesthetic appeal can determine whether one is likely to purchase a product or not, in that clients often associate good design with good quality.

Decorative borders can also be used for different models within the product line of a certain brand so that manufacturers can have different looks based on their revenues or mattress type. Whether it be a premium model with elegant embroidery or an economy model with more straightforward designs, the border cues the product identity and target audience.

Functional Durability

While the utility benefit of border machines cannot be discarded, the ornamental value added by them also cannot be denied. With time, the border of a mattress undergoes much stress due to frequent use, particularly in those areas where people sit down or rest near the edges of the mattresses. Such borders, well stitched and further reinforced by these machines, may add an extra layer of durability to the mattress in question and save it from sagging, tearing, or fraying.

This functional reinforcement is even more important in modern mattress construction when often thinner and lighter materials are used instead of traditional springs or heavy-duty foams. With the addition of stitching and design elements, this can increase the general strength of the mattress without adding layers or bulk to it.

Increased Efficiency and Production Speed

Mattress manufacturing is all about efficiency. In such a competitive field, any advantage, let alone a timesaver, may mean profitability. Of course, decorative border machines do have their place in this kind of production, automating tasks once laboriously done by hand. Such machines are designed to operate at high speeds, churning out consistent results in a fraction of the time that was used by manual stitching or other embellishment.

Moreover, decorative border machines can work uninterruptedly for long hours, with very short resting intervals, which helps manufacturers in order fulfillment without any hindrance and peak production seasons with less stress. This not only saves labor but also provides companies with faster entry of new products into the market.

The Future of Decorative Border Machines in Mattress Manufacturing

Advances in Technology

As technology is still evolving, the future of decorative border machines in mattress production looks pretty bright. Only recently has the power of artificial intelligence and machine learning begun to show its potential, and soon these machines may be able to learn from a wide range of materials, designs, and production requirements with little human intervention.

AI-driven machines could even automatically find the best stitching pattern that would work most durably and look aesthetically pleasing with insights derived from real-world usage data regarding how such mattresses are performing.

Other main development fields include material science. With the continuous evolution of new fabrics and threads that are stronger, longer-lasting, and sustainable, machines to apply decorative borders need to keep pace with these materials without problems of any kind. In mattress production, the integration of sustainable materials is now an increasingly wide-ranging trend. The same will apply to machines that work with these kinds of fabrics.

Sustainable and Customizable Production

It has also become clear that sustainability will be an ever-increasing factor in the mattress industry, with both consumers and manufacturers looking to lessen their environmental footprint. The demand for decorative border machines able to work with eco-friendly materials and use less energy during production will increase. Further still, the trend toward customization whereby consumers can order bespoke designs or features adds extra importance to these machines in mattress production.

Personalization might start going to mattress borders, where manufacturers can offer customers more personalized options, such as custom monograms, unique patterns, or even materials made from recycled fabrics. Decorative border machines will be very important in enabling this shift toward personalization and sustainability with the latest technology installed on them.

Conclusion

Decorative border machines have become an essential tool in modern mattress production, offering a range of benefits that enhance both the visual appeal and functionality of mattresses. From improving durability to allowing for intricate designs, these machines have transformed the industry, making it possible for manufacturers to produce high-quality, aesthetically pleasing products at scale. As technology advances and consumer demands evolve, the role of decorative border machines will continue to grow, shaping the future of mattress manufacturing in exciting ways.

Связанные с ними товары