- Home » The Role of Automatic Mattress Compressing and Packaging Machines

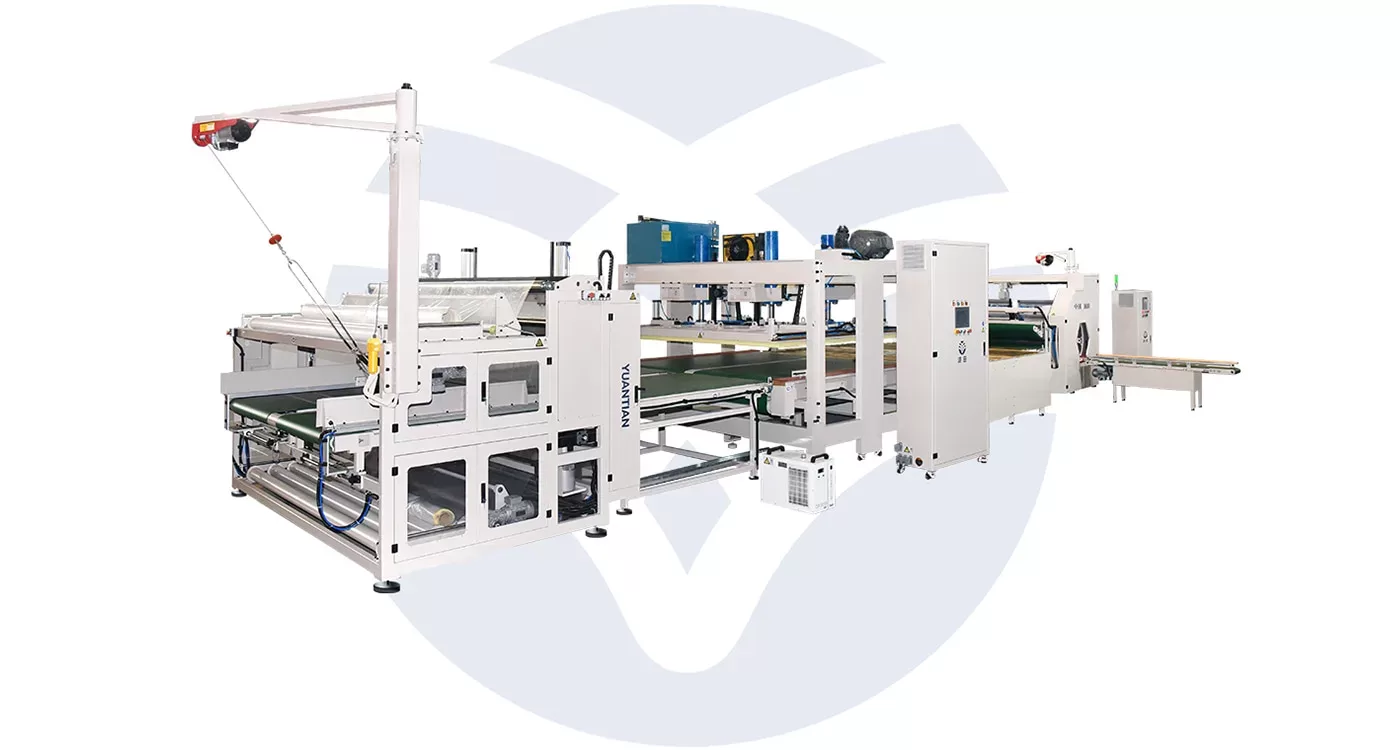

In the rapidly evolving mattress manufacturing industry, efficiency and quality are key factors that determine the success of a business. One of the most significant advancements in this field is the introduction of automatic mattress compressing and packaging machines.

These machines have revolutionized how mattresses are handled post-production, providing numerous benefits that enhance operational efficiency and product quality. This passage explores the critical role of these machines, delving into their functions, benefits, and impact on the industry.

Understanding Automatic Mattress Compressing and Packaging Machines

Primary Functions

The primary function of an automatic mattress compressing and packaging machine is to compress, roll, and pack mattresses efficiently. The primary functions of these machines include:

Compression: The volume of the mattress is decreased by compressing it. This makes it much easier to handle and move around.

Rolling: The mattress is then rolled into compact form after compression.

Packaging: The rolled mattress is then wrapped in protective material so that it stays pristine during transportation and storage.

These processes are automated to minimize human intervention and assure consistency in every operation.

Key Components

The typical automatic mattress compressing and packaging machine consists of several key components:

Compression Chamber: Where the mattress is compressed to bring down its size.

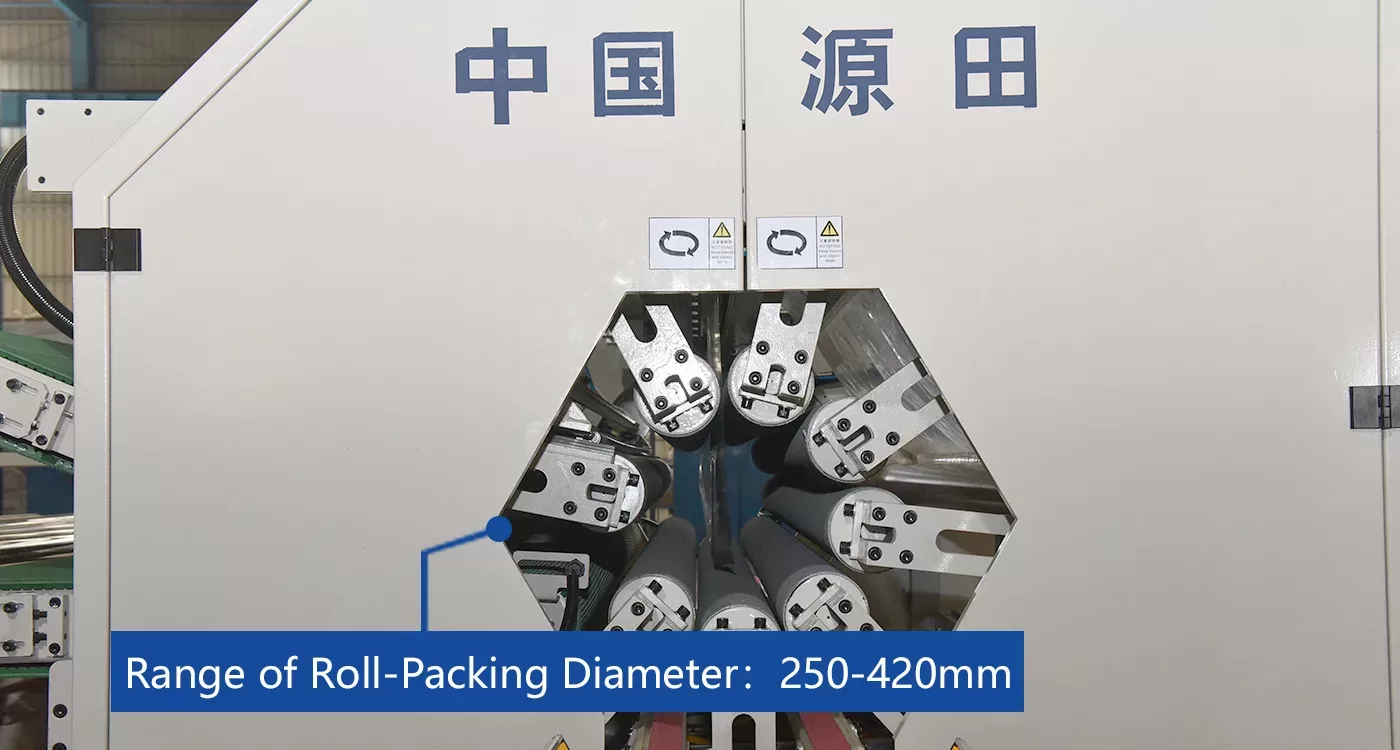

Rolling Mechanism: This part rolls the compressed mattress into a cylindrical shape and tightens it.

Packaging Unit: The final stage where the rolled mattress will be wrapped and sealed in some protective material.

All parts work together to automate the whole packaging process for any mattress, securely packing it for shipment.

Benefits of Automatic Mattress Compressing and Packaging Machines

Efficiency and Productivity

Among the many benefits of these machines is their work in increasing efficiency and productivity. By automating the compression process involved in rolling and packaging, one can easily produce many more mattresses than before in less time. This increased throughput is vital for meeting the growing demand in the mattress industry.

Cost Reduction

Automation leads to significant cost savings. Lower labor costs, reduced wastage of material, and better energy efficiency all contribute to a lowered cost. Besides, compact packaging reduces the cost of transportation and storage since more numbers of mattresses can be shipped in a single container or stored in a smaller space.

Quality and Consistency

Automatic machines guarantee a very high degree of uniformity and quality in the mattresses produced. The quality of the products from manual processes varies due to human error. In sharp contrast, automated machines ensure that each mattress is compressed and packaged with preciseness.

Environmental Impact

The use of fully automatic compressing and packaging machines also offers some ecological benefits. Tight packaging reduces carbon emissions associated with transportation because more could be shipped in fewer trips. In addition, most modern machines use recyclable materials for packaging, which is within sustainable production processes.

Impact on the Mattress Industry

Streamlining the Supply Chain

The introduction of automatic mattress compressing and packaging machines has streamlined the supply chain in the mattress industry. Package efficiency improvement enables producers to make enough quantities and respond to market dynamics very fast. This agility is very important in an industry whose consumer preferences and trends may change rapidly.

Enhancing Customer Satisfaction

Customer satisfaction is a crucial factor in the mattress industry. Automatic mattress compressing and packaging machines answer this by ensuring that the products get to the customers in excellent condition. This is likely to result in well-packaged mattresses that are damaged in very minimal instances during transit, hence bringing lesser return rates and high customer satisfaction.

Competitive Advantage

Manufacturers that invest in automatic mattress compressing and packaging machines have an upper hand in the market over other players. The machines improve operational efficiency and enhance the presentation of the product. Some well-packaged mattresses are attractive to customers, and thus manufacturers are one step ahead of those companies that package their products manually.

Future Trends in Mattress Compressing and Packaging

Advanced Automation and AI

The future of mattress compressing and packaging machines lies in advanced automation and artificial intelligence (AI). Future machines will be fitted with AI-driven algorithms that further optimize packaging. These technologies can adapt to the various mattress types and sizes to ensure that every unit is optimally compressed and packaged.

Sustainable Packaging Solutions

With environmental concerns soaring high, comes sustainable packaging solutions. Future machines will, therefore, incorporate eco-friendly materials and processes in their packaging, which are less harmful to the environment. Besides helping the environment, the shift also appeals to environmentally conscious consumers.

Integration with Industry 4.0

The integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and data analytics, will revolutionize mattress packaging. These IoT sensors, fitted within smart machines, may give real-time information about the performance of the machines and the quality of packaging. This information can be further analyzed to achieve enhanced operations, maintenance planning, and output efficiency.

Conclusion

Automatic mattress compressing and packaging machines have become indispensable in the mattress manufacturing industry. Their ability to enhance efficiency, improve logistics, and contribute to environmental sustainability makes them a valuable investment for manufacturers.

As technology continues to advance, these machines will play an even more critical role in shaping the future of mattress production and packaging. By embracing these innovations, manufacturers can stay ahead of the competition, meet consumer demand, and achieve better sustainability.

Связанные с ними товары