- Home » The Role of Automated Mattress Spring Machines in Modern Manufacturing

In the world of mattress manufacturing, efficiency, precision, and innovation are crucial for staying competitive. One of the most significant technological advancements in recent years is the integration of automated mattress spring machines. These machines have revolutionized the production process, allowing manufacturers to produce high-quality mattresses at an unprecedented scale and speed.

This article will explore the role of automated mattress spring machines in modern manufacturing, focusing on their importance, benefits, and impact on the industry.

The Evolution of Mattress Spring Production

Early Methods of Spring Manufacturing

The production of mattress springs has evolved significantly over the decades. Conventionally, mattress springs used to be manufactured by hand or with the help of manual machinery. This was an overwhelmingly cumbersome and time-consuming task.

Workers had to shape and coil individual springs before assembling them into a mattress unit. This process needed skilled labor, hence leading to high expenses and, consequently, resulted in a limited production capacity.

The Advent of Automation in Spring Manufacturing

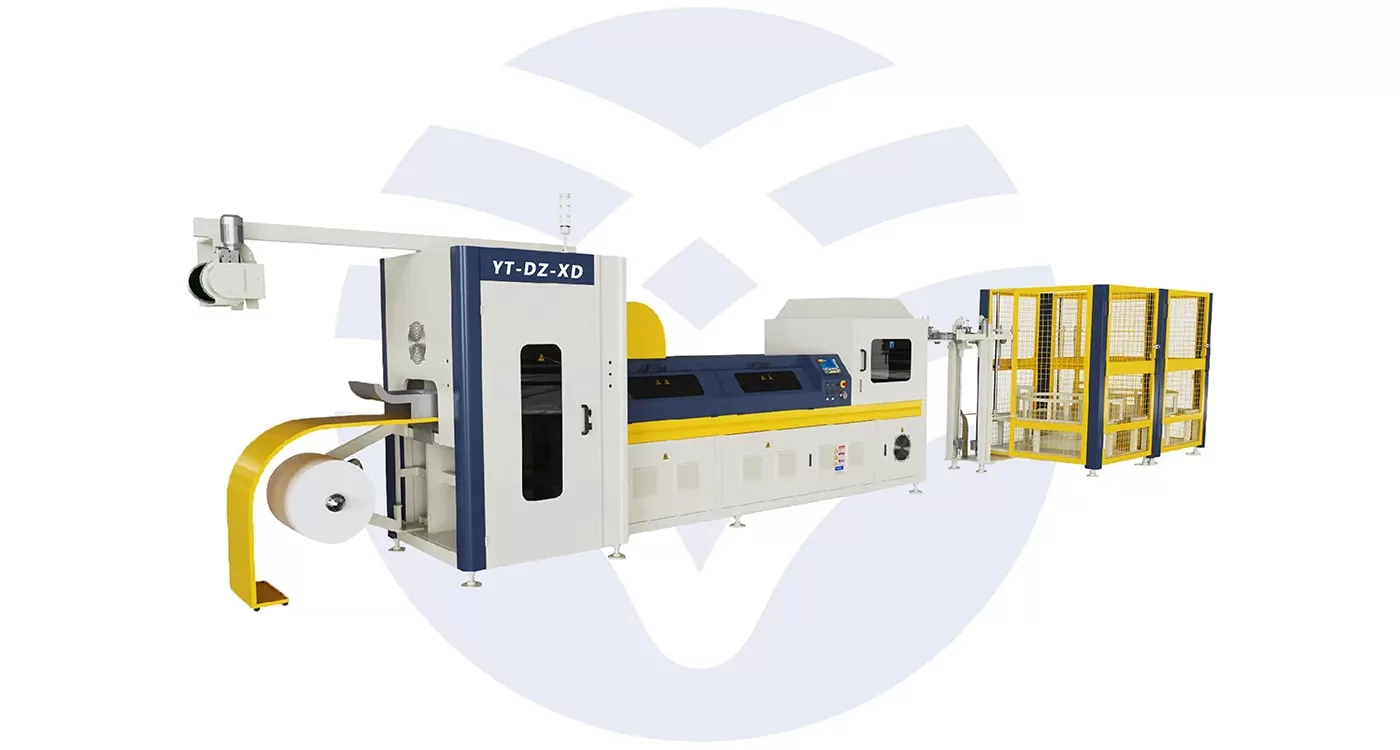

The automated mattress spring machines revolutionized the mattress industry. Advanced technology means these machines manufacture and assemble the springs automatically, reducing much of the human labor needed for these tasks.

For that reason, manufacturers can do the job faster now and with more efficiency, leading to higher volume productions at reduced costs.

How Automated Mattress Spring Machines Work

Coiling and Forming the Springs

Automated mattress spring machines are designed to perform multiple tasks simultaneously, streamlining the production process. First comes the coiling and forming of the springs. These machines can coil wire into perfect spring shapes at high speed and precision. This ensures that springs have a consistent dimension and tension.

With modern machinery, there are different types of springs, such as the Bonnell pocket and Continuous coil springs, which come according to various designs of mattresses.

Assembling the Spring Units

After the springs have been formed, the machine can assemble them into mattress units. For example, in pocket spring mattresses, the machine will place each spring into a pocket of cloth and then stitch them together. The automatic assembly has the effect of equally spaced springs that are in their correct position, something quite important for the mattress in terms of overall support and comfort.

Customization and Flexibility

The most significant benefit of an automated mattress spring machine is its modifiability for adjustments within the production process. It means adjustments in tension levels, sizes, and configurations of springs can easily be made according to customers’ preferences or market demand inside the machine. This opens up a wide vista of possibilities as far as mattress production is concerned.

Benefits of Automated Mattress Spring Machines

Increased Production Speed and Efficiency

Among the most critical advantages of using automated mattress spring machines is that they increase the production speed many times. These machines can manufacture springs and assemble mattress units at a much faster rate than any manual method.

With this much-increased speed, manufacturers will be able to meet demands when they reach a high scale, especially during peak sale periods. Additionally, the automation process lowers the risk of human error and provides consistency in quality.

Reduced Labor Costs

Automation of the spring manufacturing process significantly reduces labor costs for any given manufacturer. Fewer employees are needed to operate the machinery, and there is little to no need for skilled workers to manually coil and put the springs together.

With this decrease in labor costs, the ability of the manufacturer to offer competitive pricing, which keeps them competitive yet still generates an acceptable profit margin becomes possible.

Enhanced Precision and Quality Control

The automated mattress spring machine can give an amount of accuracy hard to achieve with manual labor. These machines can produce springs with specifications to the exact inch, thus ensuring uniformity across the production run. Such precision is required to maintain the quality of the finished mattress. For example, defects or reduced comfort can occur when there is inconsistency in the size or tension of the springs.

Also, most of the automated machines come built with quality control features, having sensors and cameras capable of detecting defects and ensuring high-quality products reach the market.

Greater Product Innovation

With automated mattress spring machines, manufacturers have the ability to innovate and experiment with new mattress designs. The flexibility that is available on these machines in terms of trying different configurations and different tension levels allows the manufacturer to make mattresses with different supportive and comfort features.

This ultimately gives the competitive edge to the manufacturer within the crowded mattress market, as they will always have new things to offer to the market once changes in consumer preference and taste happen with time.

Impact on the Mattress Manufacturing Industry

Streamlining the Supply Chain

The automated mattress spring machine has been a real disruption factor in the mattress manufacturing supply chain. Higher production efficiency, as enabled by the use of machines, lowered labor costs and allowed higher quantities of mattresses to be produced in less time by manufacturers.

This kind of smooth production helps the manufacturer to simply keep up with the market demand and maintain a regular supply of products in the market. Moreover, reduced dependency on manual labor makes the manufacturer less vulnerable to labor shortages or fluctuations in costs.

Meeting Growing Consumer Demand

Globally, demand for mattresses has risen because of the increase in population and advancement in urbanization. People today do realize the need to have quality sleep. With mattress spring machinery, an increase in volume output is realized since it automates work, hence enabling factories to meet the increased demand. This comes in handy in current markets where customers want prompt delivery and various choices of products.

Enhancing Sustainability Efforts

Besides gains in efficiency and cost, automated mattress spring machines have contributed to the industry’s roadmap to sustainability. With the high precision of the spring, the amount of waste materials emitted during production is reduced.

Also, automation in assembling has minimized energy consumption in this process, which further reduces the carbon footprint of mattress production. The interest of many manufacturers in recyclable materials also lets them continue their commitment to sustainability.

Future Trends in Automated Mattress Spring Manufacturing

Integration of Smart Technology

In the future, there is no doubt that automated mattress spring machines will continue to be integrated with smart technology. Further advances in AI and machine learning could even enable self-optimizing machines that automatically change in real-time for the betterment of efficiency and quality.

For example, sensors powered by AI may oversee the production process of springs and automatically make adjustments to achieve optimal tension and alignment. The technology would mean not only improvements in product quality but also a reduction in human intervention.

Increased Customization and Personalization

In the future, consumption will seek diversity, even mattress personalization. For this reason, the prospects for automated mattress spring machines are positive to meet such growing demand because the flexibility in producing all sorts of configurations is able to deliver it.

In the coming years, there may be additional options for customers to tailor their mattresses according to firmness level, spring type, or even the placement of certain support zones.

Continued Emphasis on Sustainability

Sustainability will continue to be one of the major issues at the core of mattress manufacturing processes, and automatic mattress spring machines will also be at the forefront in the moving of that process along. This could very well eventually encompass the use of greener materials, energy-efficient production methods, and other elements.

Recycling of old mattress springs with the use of automatic machines is another potential avenue open to manufacturers, further minimizing the industry’s environmental impact.

Conclusion

Automated mattress spring machines have transformed the mattress manufacturing industry by increasing production efficiency, reducing labor costs, and improving product quality. These machines allow manufacturers to produce high-quality mattresses at a faster rate, while also offering the flexibility to innovate and customize products to meet consumer demands.

As technology continues to advance, the role of automated mattress spring machines will only become more significant, shaping the future of mattress production for years to come.

Связанные с ними товары