- Home » The Importance of Precision Machinery in High-End Mattress Manufacturing

The mattress industry has grown phenomenally, transforming from a manual craft into a highly automated and precision-based process. Precision machinery is the backbone of high-end mattresses, making sure products are of high quality, durable, and comfortable. Advanced machinery ensures consistency, efficiency, and scalability of production in everything from assembling components making up a mattress to intricate stitching and quilting designs.

This article explores the importance of precision machinery in high-end mattress manufacturing, discussing the various types of machines used, their benefits, and how they shape the final product.

The Evolution of Mattress Manufacturing

From Manual Craftsmanship to Automation

Historically, mattress manufacturing has relied heavily on manual labor, with skilled craftsmen crafting mattresses by hand. While this could allow customization, it is extremely time-consuming and labor-intensive, hence prone to inconsistency. When high-quality mattress demand began increasing, manufacturers realized that much better ways of efficiency in production had to be considered.

Automation utterly changed the manufacturing of mattresses as the industry integrated machinery that could complete certain tasks repeatedly faster and more precisely. In this case, whereby the development will enable manufacturers to produce more mattresses in less time without compromising on quality. Nowadays, it is precision machinery that acts as the core of high-end mattress manufacturing, which enables various manufacturers to provide complicated designs and deliver first-class products.

The Role of Innovation in High-End Mattresses

Innovation is the keyword in such a competitive luxury mattress market. Upscale mattress makers are in a constant quest to put new materials, like memory foam, latex, and innovative spring mechanisms, into their products. Such unique materials do call for specialized machinery able to process these materials appropriately.

It is not only that the precision machinery allows the usage of advanced materials but also integrates them inside a mattress perfectly for ultimate comfort and support to the sleeper.

Types of Precision Machinery Used in Mattress Manufacturing

Quilting Machines

The quilting machine is one of the most important machines used in mattress manufacturing. The machine sews together various layers of fabric, foam, and padding that constitute the top layer of the mattress, also referred to as the quilt. A number of high-quality mattresses boast very complicated quilting patterns, hence requiring the most technologically advanced computerized quilting machines.

These machines can make truly complex and beautiful designs with perfect symmetry, ensuring that the aesthetic quality of the mattress will also be matched in functionality. Precision quilting machines also enable manufacturers to experiment with different stitching patterns that can provide variations in the feel and firmness of the mattress surface.

Tape Edge Machines

Tape edge machines are supposed to close the open edges of a mattress and fix the fabric in its place. It requires high accuracy in the case of luxurious mattress manufacturing, in order to give it a clean and long-lasting finish. This high-branded tape edge machine can work with different mattress thicknesses and materials, thus allowing for diversity for customers according to their specific preferences.

Precision tape edge machines are key to bringing uniformity into production. Every mattress that goes out the door is finely finished at the edge and becomes an important feature of the product in aesthetics and durability.

Border and Flanging Machines

Mattress borders provide vital structure and support. The fabric covering the sides of the mattress is attached by border machines and then sewn into place on the top and bottom panels by flanging machines. A great deal of precision is required, as a border that is mended even a little off can make the whole mattress lopsided or uncomfortable.

Most of the high-quality mattresses have reinforced borders, which need particular machines to attach them correctly. Precision border and flanging machines ensure these elements are assembled right and therefore contribute to the general mattress’s life span and stability.

Spring Coiling Machines

Spring coiling machines are a necessity in the production of mattresses containing innerspring systems. These machines manufacture small metal coils that make up the supportive core of the mattress. Precise coiling is highly important in the production of springs, as even small deviations in height or firmness of a coil could greatly impact the overall support and comfort provided by the mattress.

These are programmed on spring coiling machines during the manufacture of high-end mattresses to make coils of any particular tension to form a zoned support system, giving targeted support to specific parts of the body, such as the head, shoulders, and hips. Because coil tension can be fine-tuned, high-end mattresses ensure comfort and ergonomic support.

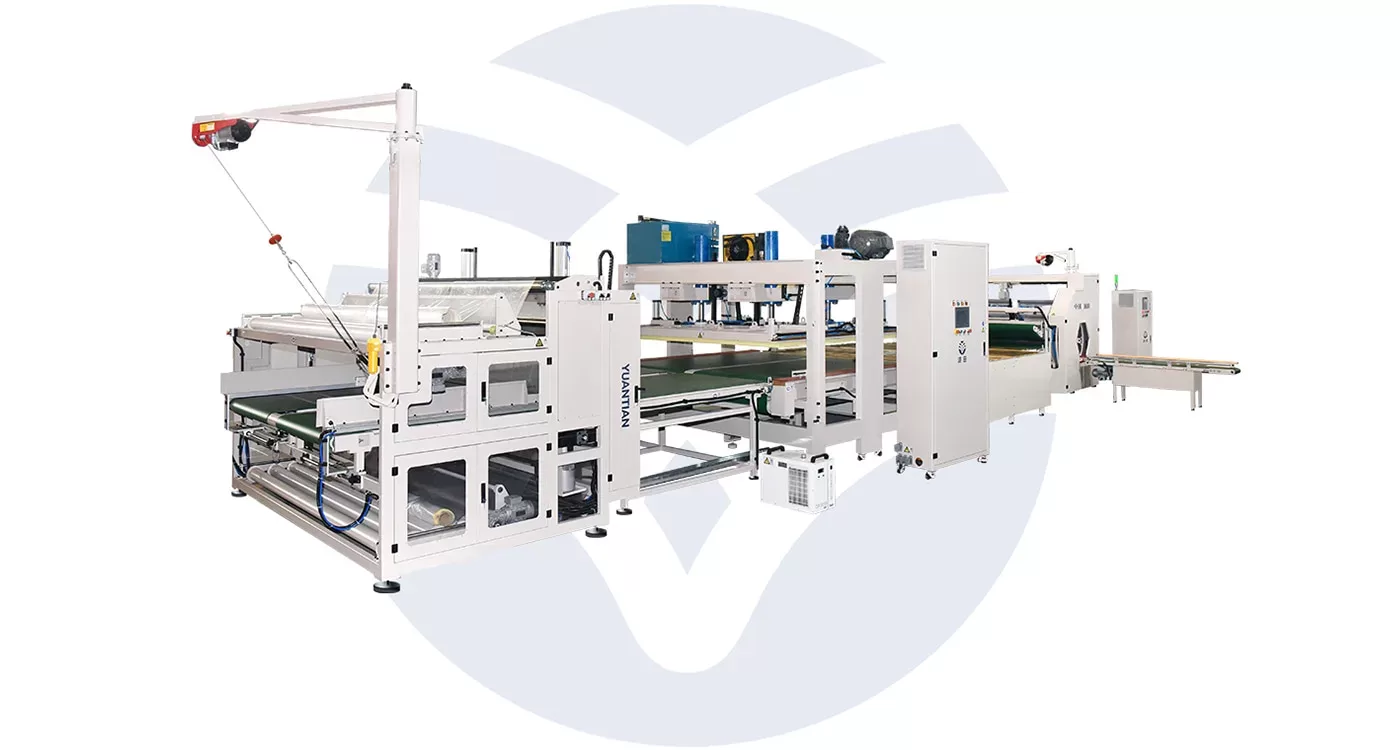

Mattress Packaging Machines

Once a luxury mattress is manufactured, it must be packaged in such a way as to deliver the product in perfect condition to the customer. The precision mattress packaging machine compresses and then rolls the mattress without any damage to its inner components. It becomes very important with memory foam and hybrid mattresses, as these can be rather delicate and may develop deformities if not handled correctly.

The advanced packaging machines compressively pack the mattresses to specifications, just right for shipping while allowing the mattress to expand to the correct shape and comfort when unpacked by the customer. All the more, precision packaging reduces the possibility of damage during transportation, thereby delivering a perfect product to the customer.

The Benefits of Precision Machinery in High-End Mattress Manufacturing

Consistency and Quality Control

The biggest advantage of precision machinery in the making of mattresses is that it offers consistency. Due to the fact that mattresses fall into the high-priced market, there are quality standards that must be met to justify a high selling price. Precision machinery ensures that every mattress is done with the same kind of care and attention to detail, reducing the likelihood of defects or inconsistencies.

Also, machines come with sensors and monitoring systems that can detect errors or deviations in real-time. This puts manufacturers in a position to take control of the error before it starts to affect the final product so that only top-quality mattresses are allowed to leave the production lines.

Efficiency and Scalability

Although it has been that high-end mattresses have their origin in custom, handcrafted production, precision machinery permits the scaling of operations without diminishing quality. Now, automated machines can work continuously, producing more mattresses in less time than manual labor. This increased efficiency translates into cost savings for manufacturers, which they can pass on to consumers through better pricing.

Besides, precision machinery allows manufacturers to experiment with new materials and designs without the need for extensive retooling. The flexibility allows high-end mattress companies to stay ahead of trends and keep up with customer demands.

Enhanced Durability and Longevity

Given that high-end mattresses are supposed to last for many years, over this period, they are expected to provide comfort and support. Precision machinery helps manufacture each component of the mattress to exact specifications to contribute toward the durability of the mattress.

Precision spring coiling machines are an example, they make coils that, over time, hold shape and maintain resilience, while advanced quilting machines generate small, evenly matched stitches that prevent the mattress cover from unraveling. In using precision machinery, the manufacturer is able to build mattresses that stand the test of time to reinforce their reputation for quality.

Conclusion

Precision machinery is the backbone of high-end mattress manufacturing, enabling companies to produce mattresses that meet the highest standards of quality, comfort, and durability. From quilting and spring coiling to tape edging and packaging, every aspect of mattress production benefits from the accuracy and efficiency of advanced machinery. As the mattress industry continues to evolve, precision machinery will remain essential in delivering the luxurious sleep experiences that consumers expect from high-end mattresses.

Связанные с ними товары