- Home » The Future of Mattress Packaging: High-Tech Machines and Sustainability

In the rapidly evolving mattress industry, innovation is key to maintaining a competitive edge. One area where this is particularly evident is in mattress packaging. The future of mattress packaging lies at the intersection of high-tech machinery and sustainability.

This combination not only enhances efficiency and product protection but also aligns with the growing consumer demand for environmentally friendly practices.

Innovations in Mattress Packaging Technology

Automated Packaging Systems

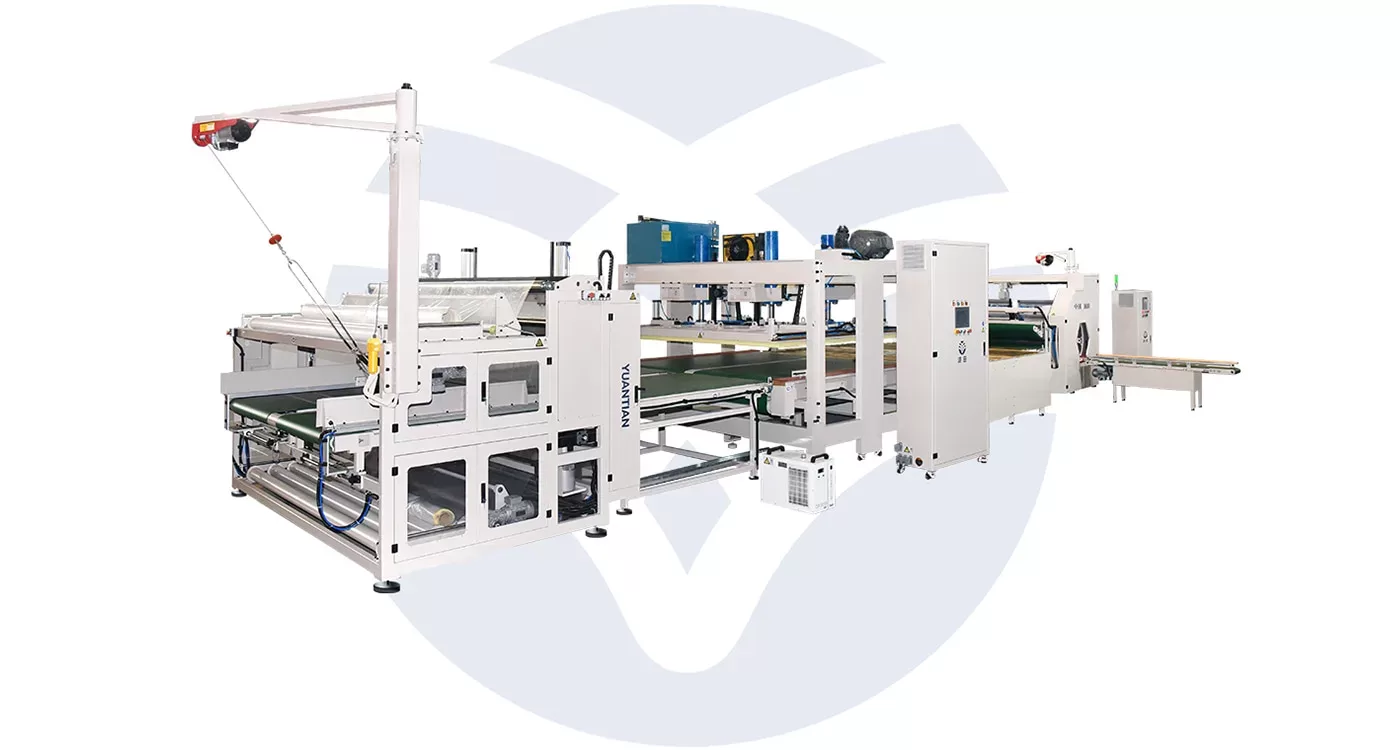

One of the significant changes underway in mattress packaging is through automation. Automated mattress packaging systems are designed to accommodate a vast range of mattress sizes and styles, guaranteeing a consistent and secure solution for packaging.

These machines can wrap, compress, and seal mattresses with precision and speed, reducing the need for manual labor and minimizing human error.

Key features of automated packaging systems include:

Adaptive Sizing: Machines that can adjust to different mattress dimensions automatically, ensuring a snug fit without manual adjustments.

Compression Technology: Advanced systems that can compress mattresses to a fraction of their original size for easier shipping and handling.

Seamless Wrapping: Machines that provide airtight wrapping to protect mattresses from dust, moisture, and other contaminants.

Smart Packaging Solutions

Other key trends include the implementation of smart technology that is incorporated into the packaging machines. It improves the packaging process through sensing and data analysis. For instance, they keep track of compression levels, as necessary, in real-time, so that each mattress is packed perfectly without damage.

Benefits of smart packaging solutions include:

Efficiency Monitoring: Receive real-time machine performance data and empower the operator to identify and act on issues.

Quality Control: Automating inspections with adjustments to maintain high standards of packaging.

Predictive Maintenance: Analyses through data that indicate when maintenance is required to avoid downtime and have a longer life of the machinery.

Advanced Materials for Packaging

The future of mattress packaging also lies in the hands of advanced materials that are designed to provide better protection and be eco-friendly. These materials will be designed to take a beating during shipping while being friendly to the environment.

Biodegradable Plastics: These are materials that break down at a much faster rate than regular plastics in the environment, hence reducing pollution.

Recycled Materials: By using recycled packaging materials, the carbon emissions of mattress companies are reduced.

Lightweight Materials: Advanced lightweight materials reduce shipping costs and lessen the damage to the environment associated with transportation.

The Shift Towards Sustainability

Eco-Friendly Packaging Practices

With increased awareness among consumers about the eco-friendliness of their purchases, the trend is forcing mattress manufacturers to take the green route in mattress packaging. There are many benefits to this approach for both the environment and the manufacturer in terms of an enhanced brand image and customer retention.

Reducing Packaging Waste

One of the important goals of green packaging is to reduce waste. Through an effective packaging system and the usage of the materials in an optimum way, it is possible to reduce extra or excessive packaging.

For example, the dimensions of the packaging should be done to fit the mattress perfectly and avoid the use of extra padding or fillers. Use fewer layers of package materials without affecting protection.

Sustainable Material Choices

When choosing eco-friendly packaging, one of the most important factors is the choice of material. Recycled cardboard is used majorly due to its durability and it can again be recycled, hence avoiding the usage of virgin paper.

Biodegradable films can provide the required protection and degrade faster in the environment than conventional plastic films.

Energy Efficiency in Packaging Processes

Modern, high-technology packaging machines are progressively being designed with energy efficiency in mind. This not only helps cut down on operational costs but also minimizes the impact on the environment from manufacturing. Energy-efficient machines use less power and often have features like:

Low-Power Modes: Machines that go into low-power modes while not in active use.

Efficient Motors: Advanced motor technologies that consume less electricity while maintaining high performance.

Carbon Footprint Reduction

Reducing the carbon footprint is a main focus for the future in mattress packaging. This shall be achieved through a number of strategies to be laid out, which include:

Local Sourcing: Sourcing packaging material from local providers, in comparison with others, will help lessen emissions related to transportation.

Renewable Energy: Installation of renewable energy at production facilities, for example, solar or wind power.

Carbon Offsetting: Projects that offset carbon emissions are to be invested in, such as tree planting and renewable energy projects.

The Benefits of High-Tech and Sustainable Packaging

Enhanced Product Protection

Advanced mattress packaging machines secure the mattresses and reduce any potential damage that may be caused by transportation. This not only saves the product itself but also reduces the number of returns and replacements, which sometimes cost a lot and are also bad for the environment.

Operational Efficiency

Automation and smart technologies make packaging processes easy by reducing the involvement of manual operation. In this way, faster production time is achieved with lower labor costs and increased overall efficiency.

Besides, predictive maintenance and real-time monitoring improve operational efficiency by preventing unexpected breakdowns and opting for the optimization of machine performance.

Consumer Satisfaction

Eco-friendly packaging appeals to green consumers. Such practices will help mattress manufacturers attract and retain customers who value the green factor highly. Good quality packaging will ensure the protection of the mattress and thus leave the consumer receiving products in perfect condition, thereby enhancing customer satisfaction and loyalty.

Regulatory Compliance

Governments and regulatory bodies are increasingly coming up with sterner guidelines as regards the quantum of packaging wastes and addressing sustainability.

Manufacturers should therefore stay ahead of these regulations by adopting advanced and eco-friendly solutions to avoid fines and penalties that may be levied on them. Compliance can also enhance a company’s reputation and can be a worthwhile inclusion in a marketing strategy.

Challenges and Considerations

Initial Investment Costs

Even though these high-tech and green packaging solutions are so much in demand, one of the obstacles to implementing them is the up-front cost. State-of-the-art machines and green materials can be very expensive at the front end. Long-term savings on operational costs and probable customer loyalty will compensate for the initial investments.

Technological Integration

Another complex task is the integration of new technologies within the existing lines of production. This requires planning and coordination in a way so that new machines and their processes run well with the present systems. Another key aspect is the training of staff to run and service these sophisticated machines.

Balancing Sustainability and Performance

Though the long-term sustainability of materials and processes involved in packaging is of immense importance, it should not come at the cost of protection performance.

This requires a trade-off between sustainability and performance, entailing continued research and development aimed at spotting such materials and technologies that offer good environmental benefits while guaranteeing superior product protection.

The Road Ahead

Continued Innovation

Advancements in technology and rising demands for sustainability will see the mattress packaging industry moving forward. Not stopping, innovation will introduce new materials, smarter machines, and more efficient processes. Those companies investing in research and development will lead the charge toward that change.

Collaboration and Industry Standards

This will lead to an even faster rate of adoption of such sustainable practices across the industry. The establishment of industry standards on packaging will create the possibility of taking a similar line of approach with regard to sustainability and quality. In collaborative effort, manufacturers, suppliers, and technology providers are well-positioned to drive big process improvements in packaging.

Conclusion

The future of mattress packaging is bright, with high-tech machines and sustainable practices leading the way. Automated and smart packaging solutions enhance efficiency and product protection, while eco-friendly materials and processes address the growing demand for sustainability.

Despite challenges such as initial investment costs and technological integration, the benefits of adopting these advanced packaging solutions are substantial. As the industry continues to innovate and collaborate, the goal of a more sustainable and efficient mattress packaging process is well within reach.

Связанные с ними товары