- Home » Streamlining Operations with Advanced Mattress Packaging Machines

Businesses in today’s competitive marketplace always look for ways to enhance efficiency, reduce costs, and improve product quality. Advanced mattress packaging machines rank among those technological advancements that have completely revolutionized the mattress industry. These machines are advantageous on many counts, from operational efficiency to being more eco-friendly. In this article, we delve into the impact of these machines under various aspects of production and logistics.

Benefits of Advanced Mattress Packaging Machines

Enhanced Efficiency in Production

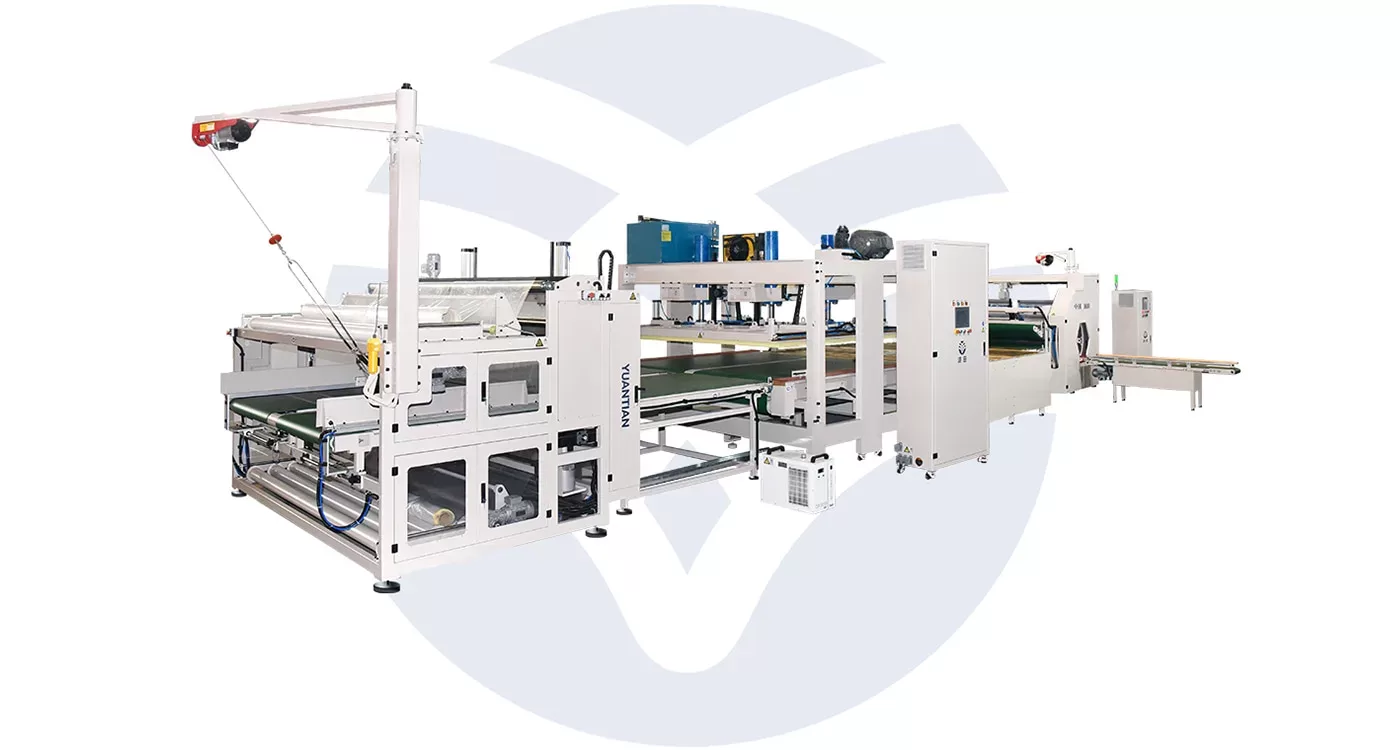

The most striking aspect of advanced mattress packaging machines is their speed. Compared to the traditional method of packaging, which involves people and hence is slow and not often consistent, advanced mattress packaging machines can package mattresses in a fraction of the time and do so consistently.

It is even easier with automatic systems wherein the mattresses are compressed, rolled, and sealed in a single continuous process. Minimum time wastage between production and shipment is reduced due to which manufacturing companies can easily fulfill high demand without compromising on quality.

Reduction in Labor Costs

Labor-intensive processes are costly to an organization and prone to some human error. Advanced packaging machines will enable companies to reduce their dependence on human intervention. Machines perform repetitive tasks with greater accuracy, hence guaranteeing consistency and reduced errors.

Although the initial investment into packaging machinery is apparently too high for any manufacturer, potential long-term savings from labor costs usually outweigh the upfront investment. Moreover, the reshifting of employees to positions that are more strategic may contribute to improved productivity at the workforce level.

Improved Packaging Quality

Consistency in Packaging

Consistency in packaging creates professionalism for the brand in the eyes of the customers. Advanced machines are provided with accurate controls that ensure each mattress is packaged to exact specifications. This level of consistency removes the risks of damages during transit due to improper packaging.

Space Optimization

Modern packaging machines can compress mattresses down to much smaller volumes. This is quite beneficial for both the manufacturer and retailers of the mattresses. Mattress compression reduces their occupied space thereby cutting down on the processes of storage and transportation. This not only optimizes logistical challenges but also contributes to environmental sustainability through the reduction of fuel consumption and its resulting emission during transport.

Contribution to Environmental Sustainability

Reduced Material Waste

Sustainability has become a major concern for business entities and consumers. Advanced packaging machines have been designed to minimize material waste by using the exact amount of packaging material. The manual methods lead to overconsumption of plastic or other non-recyclable materials that result in environmental decay.

Eco-Friendly Packaging Options

Most of these machines work with either biodegradable or recyclable materials, which may just as well enable the manufacturer to fall in line with eco-friendly practices. The changeover is not only reducing the ecological footprint but also enhancing brand value for the environmentally aware consumer.

Integration with Smart Technologies

Data-Driven Decision Making

IoT and AI-powered analytics have already found their place in many advanced mattress packaging machines, making the running of a manufacturing line even smoother. Manufacturers can have full control over the performance of every machine in real-time, bottlenecks are discovered instantly, and operations are swiftly optimized.

For instance, sensors can monitor compression levels and advise manufacturers on potential malfunction events before these create costly repairs. That is how predictive maintenance works: to avoid bumpy operations and zero downtime.

Customization Capabilities

The ability of modern machinery to customize packaging according to a particular product or branding requirements also justifies this fact. Be it branded labels or unique formats of packaging, all such features help business entities gain momentum in the competitive market.

Financial and Strategic Benefits

Faster Return on Investment

Advanced packaging machines guarantee a quicker return on investment due to the efficiency and cost-saving alternatives of the machinery. Minimization in labor costs, optimization of material usage, and decrease in wastage enable business entities to recover the initial investment in a shorter period.

Competitive Advantage

Within competitive industries, market leadership often follows from operational efficiencies. Indeed, companies using advanced packaging machines are able to handle greater volumes of product, ensure quicker delivery, and maintain high packaging standards. In such a way, they stand to gain favorable positioning within the market, where the stakes are speed and reliability.

Challenges and Considerations

Initial Investment Costs

Irrespective of the numerous advantages offered by high-end packaging machines, their cost is significantly expensive. Therefore, companies need to be highly considerate about their budgets and reflect on the probable return on investment they will result in case they decide to invest in any such machinery. This is even more the case with small-scale manufacturers who may not be able to afford them unless they have a long-term growth plan.

Training and Maintenance

Skilled manpower is required to operate and maintain the machines. Investments are needed in training the employees by the companies, too, for smooth operations. There is a need for periodic routine maintenance, too, in order to avoid sudden breakdowns that may reduce its lifespan.

Conclusion

Advanced mattress packaging machines that offer unparalleled efficiency, quality, and sustainability have emerged in the industry to date. These machines will facilitate efficient operations, thereby giving an edge in the sector through automation of labor-intensive tasks, optimization of materials usage, and integration of smart technologies.

While the initial investment and training requirements may pose challenges, the long-term benefits of enhanced productivity, cost savings, and environmental responsibility outweigh these concerns. For businesses aiming to thrive in the modern market, embracing advanced packaging technology is not just an option, it’s a necessity.

Связанные с ними товары