- Home » Streamlining Mattress Production: The Impact of Automated Machinery

Throughout the past years, automation has played an important part in changing how mattresses are made. Automated machinery has streamlined production, reducing labor costs, improving product consistency, and increasing overall efficiency.

From spring-making to foam cutting, sewing, and assembly, nearly every aspect of mattress production has benefited from the implementation of automated systems. This article explores how automated machinery impacts the mattress production process, offering insight into its key features, benefits, and influence on the industry.

The Role of Automation in Mattress Manufacturing

Automation has developed to be one of the mainstays of mattress production today, offering so much more than previous manual methods. The machinery used in this industry can vary from simple, specific machines producing individual components of the mattress, like springs or foam, to fully automated assembly lines that take care of the whole mattress production process.

In the past, mattress production relied heavily on skilled labor for tasks such as spring assembly, fabric cutting, and stitching. These processes were time-consuming, prone to human error, and limited in scalability. With the introduction of automated machinery, manufacturers can now produce mattresses faster, with greater precision and consistency, and in larger quantities.

Automation has evolved with increased demands for higher-quality mattresses at lower costs, and the shifting consumer preference. With increased competition in the bedding industry, automation enables producers to stay ahead of their competitors through further efficiency, reduced waste, and increased customization.

Key Benefits of Automated Machinery in Mattress Production

The integration of automated machinery into mattress production has led to several key benefits that have reshaped the industry.

Increased Efficiency and Productivity

Their main advantage is that automated machinery raises the speeds of production considerably. Automatic machines can carry out tasks related to spring coiling, foam cutting, and fabric sewing at high speeds compared to manual labor. The fast nature of production allows many manufacturers to meet the demand volume effectively with the delivery of quality.

These machines include innerspring unit makers or even those that cut memory foam, for instance. These machines can run with very minimal assistance from operators and therefore can have big batches of mattress components made in a fraction of the time that manual operations would require. Greater efficiency naturally results in shorter production cycles, which translates into faster delivery times and increased customer satisfaction.

Consistency and Precision

In mattress manufacturing, precision is going to mean a great deal in terms of the quality and durability of the products. Automation machinery is designed with a lot of accuracy for producing components that meet exact specification criteria regularly. Be it the consistent coiling of springs in a Bonnell spring unit or the precise cutting of layers of foam, automation ensures that every mattress component is identical, leading to more overall uniformity in the final product.

Minor inconsistencies in spring tension, fabric alignment, or foam cutting provide a great impact on performance and comfort in manual productions. These inconsistencies are eliminated by automated machines, thus improving the overall quality of the finished mattress.

Labor Cost Reduction

In the process, much of the need for human labor is replaced, considerably reducing the mechanism’s costs in terms of labor expenses. While some skilled employees are needed to run and manage the operation of the machines, the total number required to make high volumes of mattresses is considerably lower.

This savings benefit is more critical for those manufacturers operating in high labor cost regions. By investing in this automated machinery, they are in a position to remain competitive in the global marketplace while maintaining high production volumes.

Enhanced Customization Capabilities

Automation can enable mattress makers to provide a much broader range of personalization options to consumers. Advanced automated equipment can be programmed for different sizes, firmness, and design options without requiring significant retooling or manual adjustments.

These could be fitted with different patterns and densities to accord with various degrees of support and comfort sought by mattress manufacturers. Equally, various patterns and materials may be realized with personalized mattress designs using programmed automatic stitching machines.

This flexibility is important to the changes in consumer demand for personalized products. Such demands are increasingly met without compromising efficient production schedules through the use of automated machinery.

Types of Automated Machinery in Mattress Production

Automated machinery represents a wide range of mattress-making processes, ranging from processing raw materials to the final product assembly. Some of the major types of machinery applied in the industry include the following.

Spring Coiling Machines

The coiling machines are critical equipment required to produce the spring units of most conventional mattresses. These coiling machines coil wires into springs as continuous lengths and automatically cut them to desired lengths, forming them as units. Capable of running at high speeds, these machines can manufacture consistent spring units effectively by offering high accuracy in control.

Foam Cutting Machines

These machines cut memory foam, latex foam, or polyurethane foam into layers that form the core of most modern mattresses. Automatic cutters employ advanced technologies like Computer Numerical Control to make precise cuts for every layer of foam to the exact dimensions needed for the mattress.

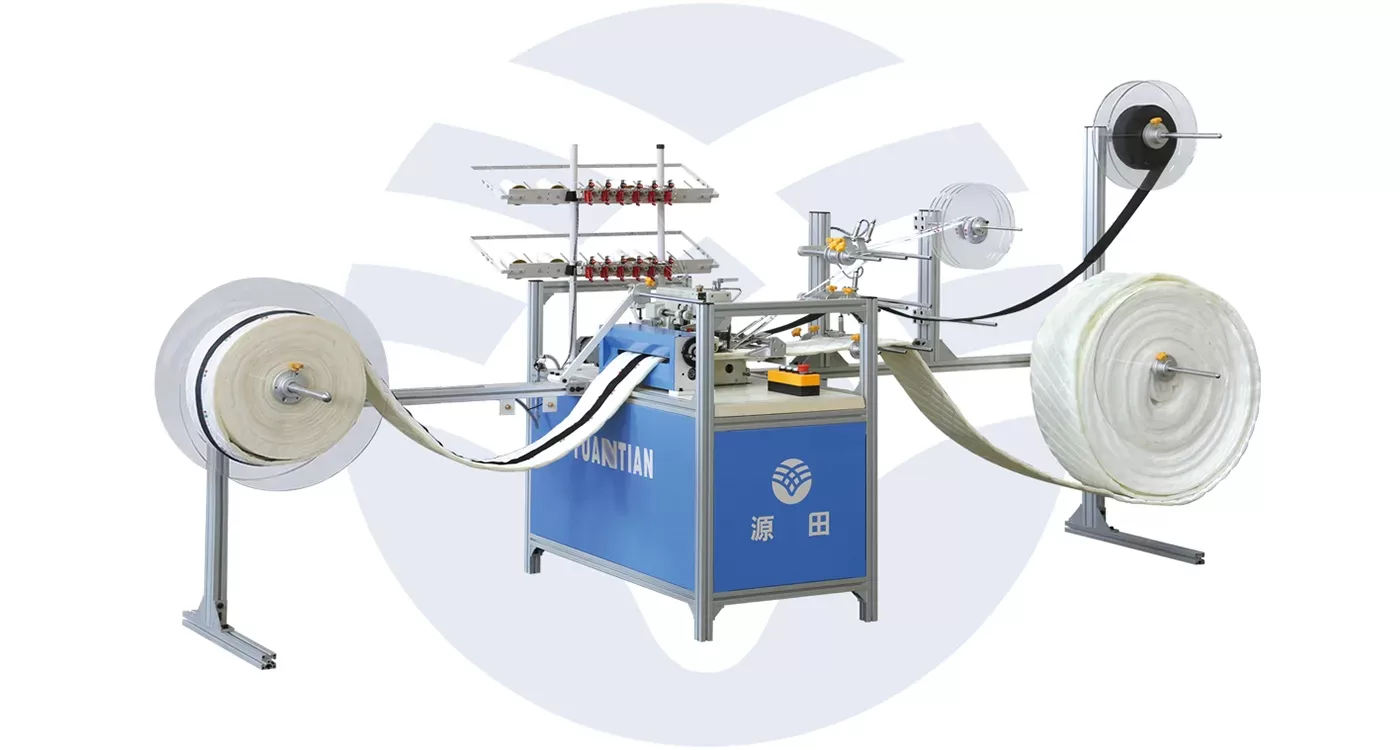

Quilting and Sewing Machines

Quilting and sewing machines join the various layers of fabrics and foams together that are used to make a mattress cover. The machines are available with computer controls to run various stitch patterns and will handle a range of fabrics for aesthetic effects in the appearance of the mattress, to give it shape and to provide structural integrity.

Mattress Assembly Systems

This is where fully automated mattress assembly systems come in handy to speed up the tail-end of the mattress manufacturing process. These systems bring together the innerspring unit, foam layers, and fabric cover, among other components, into one complete product. An automated assembly line can handle a range of mattress sizes and types, minimizing manual interference and hastening production times.

The Future of Automation in Mattress Manufacturing

As automation continues to evolve, its role in mattress manufacturing is expected to expand. Advances in robotics, machine learning, and artificial intelligence (AI) are likely to lead to even more sophisticated machines capable of self-monitoring, troubleshooting, and optimizing production processes in real-time.

In the near future, we may see more integration between automated machinery and smart manufacturing systems. These systems could collect and analyze production data to further enhance efficiency, predict maintenance needs, and customize mattress production based on consumer trends and preferences.

Conclusion

Automation has revolutionized mattress production, bringing advantages in efficiency and precision while allowing for higher levels of customization at lower labor costs. As technology continues to advance, automation will play an even more significant role in shaping the future of mattress manufacturing, driving innovation, and maintaining competitiveness in a rapidly evolving industry.

Связанные с ними товары