- Home » Revolutionizing Mattress Packaging: The Latest Advances in Compression and Boxing Machinery

In these fast-changing times, the demand to be more efficient, sustainable, and innovative in mattress manufacturing has never been greater. As consumer expectations grow and e-commerce takes over as the leading platform in shopping, advanced kinds of mattress packaging solutions catapult manufacturers forward toward new technologies.

Among these, mattress compression and boxing machinery have emerged as key players in revolutionizing the industry, offering solutions that meet the dual demands of practicality and cost-effectiveness.

The Need for Advanced Mattress Packaging

Growing E-commerce Trends and Their Impact

The rise of e-commerce has changed how consumers are buying mattresses. Online mattress shopping brings convenience but also creates challenges around delivery logistics. Traditional mattresses, with their bulky size and weight, are costing money and are cumbersome to ship.

The need to compact these has led to the development of the latest compression and boxing machinery, able to let mattress manufacturers pack their mattresses into a more compact form. This would help reduce not only shipping charges but also make delivery and setup relatively easy for end customers.

Environmental Considerations and Sustainability

Sustainability is one of the major trends in the mattress industry. Consumers are becoming increasingly environment-conscious regarding their purchases, and businesses are endeavors operating in ways that will help secure a greener future.

Advanced mattress packaging is a necessity for ensuring sustainability through reduced usage of packaging material and carbon footprint generated from transportation. Compression and boxing machinery enable the packaging of mattresses more effectively, reducing waste and enabling a more environmentally responsible supply chain.

How Mattress Compression Machinery Works

The Science Behind Mattress Compression

Mattress compression machinery works by applying uniform pressure to thin the thickness of the mattress so that it becomes easy to package and transport.

Mattresses are compressed by being put in a chamber wherein hydraulic or pneumatic pressure is applied, then vacuum-sealed with plastic to hold this compressed state until such time it reaches the consumer. It is sophisticated technology developed in mattress compression to ensure its structure and comfort when decompressed.

Key Benefits of Compression Technology

The most important advantage associated with mattress compression technology is the drastic reduction in size for the purpose of packaging. This is because compressed mattresses occupy less space, meaning that more units can be shipped in a single container or truck. This leads to drastic reductions in transport costs and a reduced carbon footprint.

Moreover, compressed mattresses enhance handling related to the delivery process for better efficiency and reduce potential damages in transit. This can be very beneficial from a consumer perspective. Being able to take delivery of a mattress in a compact box, easily moved into tight spaces, is very desirable.

The Role of Boxing Machinery in Mattress Packaging

The Evolution of Mattress Boxing Machinery

From the early days of mattress manufacturing, boxing machinery has undergone significant development. Traditionally, mattresses were shipped in full size and packaged in large, sometimes costly packages.

Developments in boxing machinery today make it possible to compress mattresses neatly, fold them, and then place them in compact boxes. This has been driven by the need for more efficient packaging solutions with modern distribution channels, particularly e-commerce.

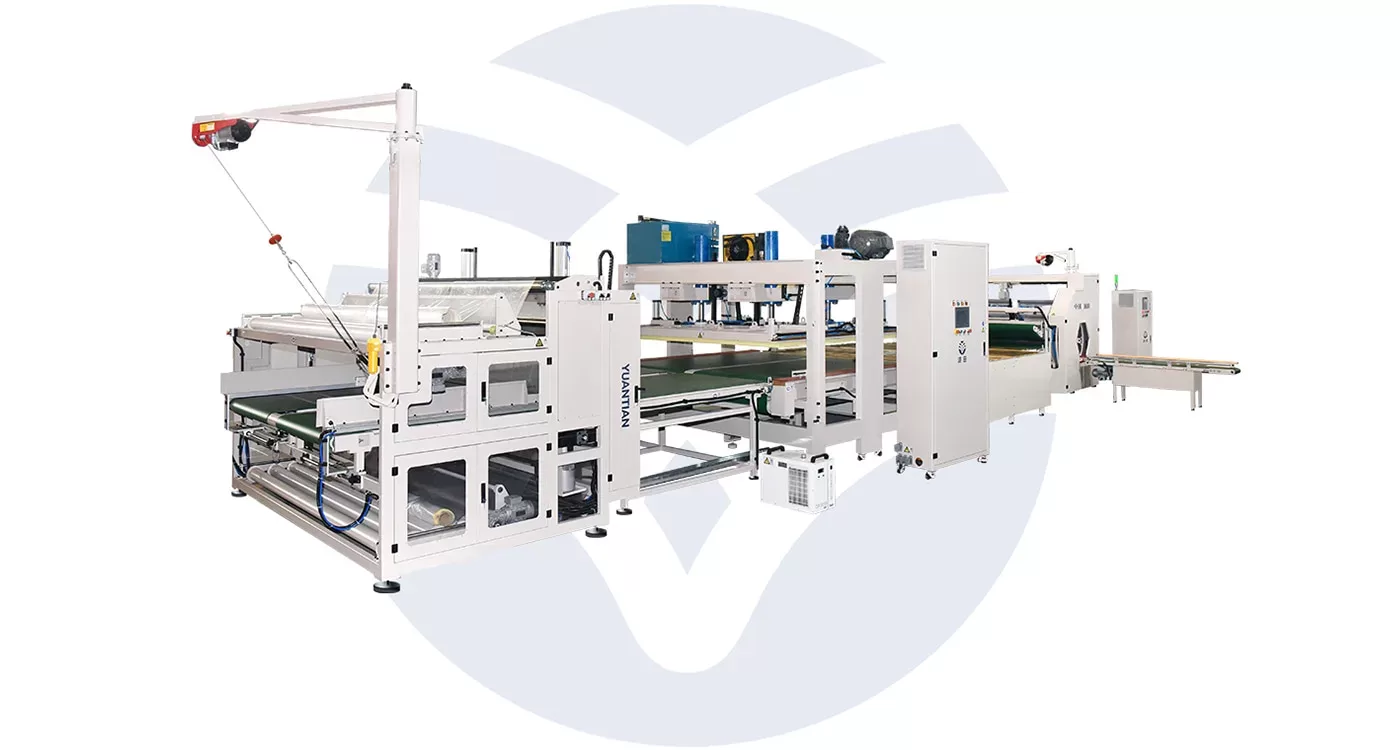

Innovations in Automated Boxing Systems

Modern boxing machinery is well automated to take mattresses through its operations at high speed with very minimal human involvement. This means a folded and boxed mattress is accurately done in regard to ensuring the finished product is secure and ready to ship.

In this area, there are innovations developed such as including robotics and smart technology that can switch settings as the size and type of mattress vary. This flexibility allows the manufacturer to go through the packaging of a wide range of models of mattresses on a single system. This increases operational efficiency.

Enhancing Efficiency and Reducing Costs

Streamlining the Packaging Process

This has deeply integrated compression and boxing machinery into the mattress manufacturing process, greatly streamlining packaging operations. Manufacturers are able to increase throughput while bringing down labor costs due to the automation of the compression and boxing stages.

These machines process hundreds of mattresses per hour, way beyond what manual methods of packaging can achieve. Therefore, this leads to a faster production line, which can serve the ever-growing demand for mattresses, especially in the e-commerce sector.

Cost Savings and Return on Investment

Advanced packaging machinery gives cost savings beyond labor reduction. Mattresses that are compressed and boxed take less space, hence, more of them can fit into shipping containers, thus saving money in transport costs.

Furthermore, much more effective packing means less packaging material used overall. For manufacturers, these several compelling savings generally offset the higher upfront investment of compression and boxing machinery, thereby making it a very smart financial decision.

Addressing Quality and Consumer Satisfaction

Maintaining Mattress Quality During Compression

One of the major concerns about mattress compression is the possible damage it can cause to the quality of the mattress. Modern compression machinery, however, is designed to keep the comfort and support features of the mattress intact.

This process is very controlled so that no damage is done to the internal structure of the mattress, and it will fully expand to its intended size once the packaging is removed. Improvements in materials and engineering have been made to ensure that quality is maintained, many mattresses these days are specifically designed to outlast the compression process.

Improving the Unboxing Experience for Consumers

The unboxing experience has become a pivotal aspect in the sphere of consumer satisfaction. With the rising popularity of unboxing videos and social media, the presentation of a product at the time it arrives can make all the difference. Advanced boxing machinery makes sure that mattresses are neatly packaged and quite easy to unbox.

Many systems also offer the possibility of custom branding on the packaging, enabling more exposure and attractiveness for the brand. For consumers, it means that they can set up a mattress easily and quickly on their own, without requiring professional help, adding great value.

Future Trends in Mattress Packaging Technology

The Rise of Smart Packaging Solutions

As technology continues to advance, the future of mattress packaging may involve smart packaging solutions that offer additional benefits. These could include sensors embedded in the packaging to monitor temperature, humidity, and other environmental factors during transit, ensuring that the mattress arrives in optimal condition.

Smart packaging could also enable tracking and provide real-time updates to consumers, enhancing transparency and customer satisfaction.

Sustainable and Eco-friendly Packaging Innovations

This will remain the continuous driver for innovation regarding mattress packaging. Further development may even take into account biodegradable or recyclable packaging material that will offer additional environmental protection.

Besides, improvements in compression technology might further support smaller and more effective packaging, enabling manufacturers to reduce waste and thereby enhance their sustainability credits.

Conclusion

Advancements in mattress compression and boxing machinery have made the modern ways of e-commerce and sustainability much easier while driving efficiency with lower costs. As these technologies further evolve, they will play a critical role in shaping the future of mattress manufacturing and distribution.

Связанные с ними товары