- Home » Reducing Waste and Improving Efficiency with Modern Mattress Flanging Machines

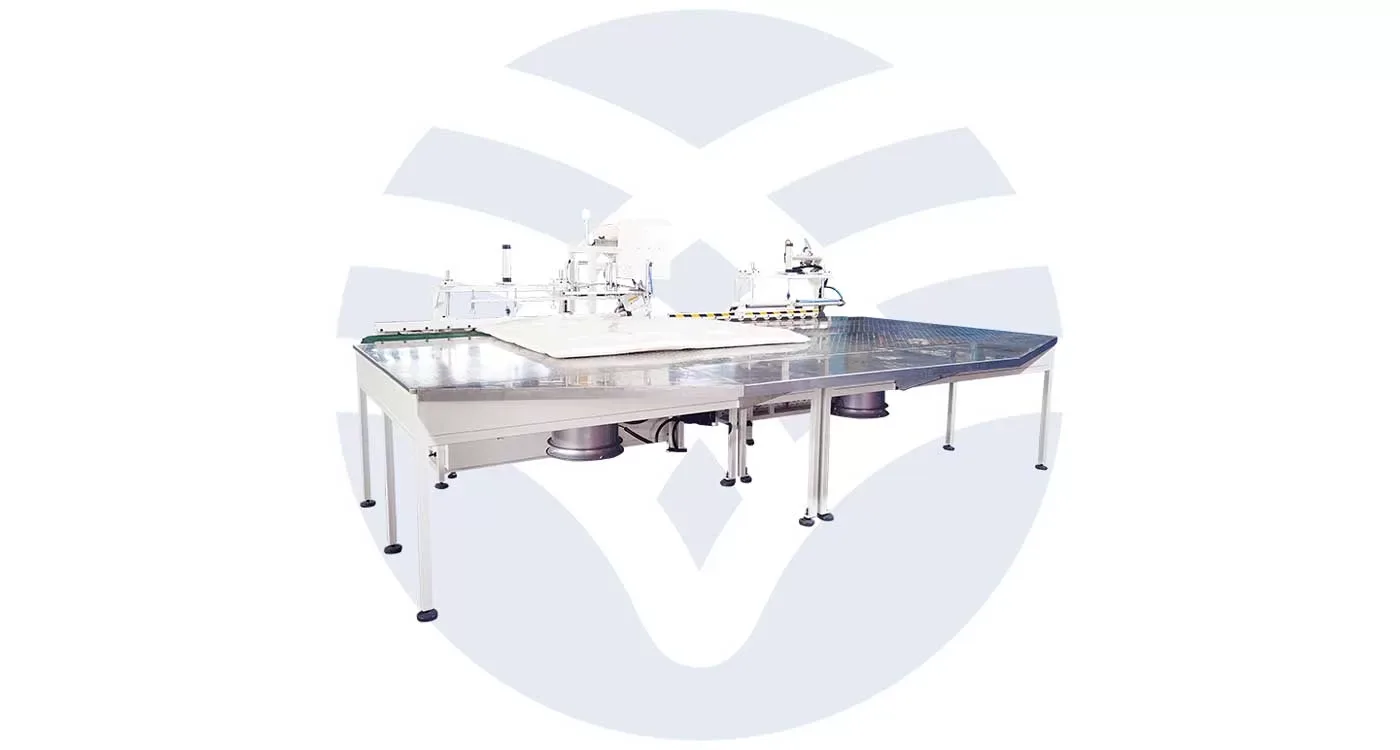

Mattress manufacturing is an industry where precision, efficiency, and waste reduction are key to maintaining profitability and sustainability. Among the various machines used in mattress production, flanging machines play a critical role in attaching the borders of the mattress to the top and bottom panels.

Mattress flanging machines have seen considerable development, introducing versatile features that strive to minimize waste and at the same time deliver high productivity. This article looks at the advanced features incorporated in modern mattress flanging machines and how they contribute to waste reduction and improved efficiency in mattress making.

The Evolution of Mattress Flanging Machines

Mattress flanging machines have progressed a lot from the earlier models. Earlier, such machines were quite simple and used to perform only simple stitching operations. However, as the demand for better quality and diversified designs in mattresses increased, it became necessary that manufacturers also get more sophisticated machinery that can perform complex tasks with a higher degree of precision and speed.

In this evolution, computer-controlled flanging machines appeared to be the most important development. These machines are backed up by very sophisticated software, which allows the best control over stitching patterns, tension, and stitching speed. Programmed and stored flanging patterns considerably facilitated manufacturers in producing a very wide range of mattresses without manual settings, which is time-saving. It also makes errors less likely, resulting in low waste and high efficiency.

Key Features of Modern Mattress Flanging Machines

Modern mattress flanging machines come with some of the most advanced features in the market to ensure high productivity, reduced waste, and delivery of a first-class product. Some of the key features include:

Automated Edge Control: This feature will make certain that the seaming is perfectly aligned in a straight line with the borders of the mattress panels. This will reduce the chances of misaligned material wastages and will bring uniformity in the finish of all mattresses manufactured.

Adjustable Stitching Speed: This makes it possible for the operator to vary the performance of the machine to suit the kind of material being worked on. For instance, delicate fabrics may require a slower stitching speed to prevent damage, while more robust materials can be handled at higher speeds to increase productivity.

Programmable Patterns: Most of the new flanging machines come with accessories for programmable stitching patterns so that changeover from one style of stitching to another comes easily to the manufacturers. This means manufacturers producing a myriad of mattress styles can benefit in ways where there are none or minimal chances of error because manual involvement is reduced through this flexibility.

Thread Tension Control: Constant thread tension is very important to make sure that the seams of the mattress are strong and nice looking. The advanced flanging machine features automatic thread tension control, which varies the tension in real time to accept different fabrics of thicknesses and types. This feature assures that minimum thread breakage and thread usage happen while wasting minimum material.

Real-Time Monitoring and Feedback: The most recent flanging machines are equipped with sensors and monitoring systems that provide information on the performance of the machine. An operator can therefore make any needed adjustments in the shortest possible time without wastage of material or stoppage of production.

Waste Reduction Through Precision and Automation

One of the primary ways in which modern mattress flanging machines contribute to waste reduction is through increased precision. In the past decade, the traditional flanging methods incorporated the experience of operators in manual adjustments that ended with inconsistencies in the final product’s quality. Such inconsistencies would affect not only the quality of the mattress but also the amount of material scrapped or corrected by operators.

Most of these challenges have been eliminated through automation. It enables consequent results to be made while the flanging machines controlled by computers allow for very little waste of material. The automated edge control and control of thread tension make sure the fabric is treated very gently, therefore eliminating damage and rework.

Furthermore, since the programming and storage of different flanging patterns is possible, material use for each mattress design could be optimized. By selecting the most effective stitching patterns for a given design, fabric manufacturers could aid in reducing waste fabric and hence material resources could be used more effectively.

Enhancing Efficiency in Mattress Production

In addition to reducing waste, modern mattress flanging machines significantly speed up the production of mattresses. Automation and precision provided by these machines give manufacturers a better chance to produce mattresses at high speeds without compromising quality. This is required considering that the market is becoming highly competitive, and therefore, manufacturers usually have strict deadlines to meet but with high standards of quality.

One of the ways flanging machines enhance efficiency is by minimizing setup time for machines and adjustments. Programmable patterns and automated controls enable operators to change from design to design in quick succession without requiring long manual adjustments. This saves much time and reduces the possibility of errors, thus yielding fewer rejected products and less downtime.

Moreover, modern flanging machine designs have real-time monitoring and feedback systems that provide alerts to an operator as to what to troubleshoot and repair. This proactivity prevents small problems from becoming production line stoppages and, therefore, major problems.

The Role of Training and Maintenance

While modern flanging machines offer numerous benefits, it is important to note that their effectiveness depends on proper training and maintenance. The operators should be trained on proper use of the machines and features provided, how to adjust them when need be, and others, so that these machines can work to their full potential while risks of errors are reduced.

Regular maintenance is also important for the effective functioning of the machine at its best. It includes frequent checking of stitching elements, thread tension systems, and monitoring sensors. Manufacturers, through regular servicing, can prevent breakages and can elongate the life span of the machines, thus improving efficiency and saving in the long run on the cost.

Conclusion

Modern mattress flanging machines have revolutionized the mattress manufacturing industry by reducing waste and improving efficiency. The advanced features of these machines, such as automated edge control, programmable patterns, and real-time monitoring, allow manufacturers to produce high-quality products with minimal material wastage.

As the industry continues to evolve, the role of these machines in promoting sustainability and enhancing productivity will only become more significant. Proper training and maintenance will be essential to ensuring that manufacturers can fully realize the benefits of these advanced machines, paving the way for a more efficient and environmentally friendly future in mattress production.

Связанные с ними товары