- Home » Reducing Production Time with High-Speed Mattress Quilting Machines

In the highly competitive mattress manufacturing industry, speed and efficiency are needed to cater to the ever-growing needs of consumers. Conventional mattress quilting is time-consuming and labor-intensive, hence, many manufacturers prefer high-speed mattress quilting machines. Such advanced machinery will have a considerable effect on manufacturing time, quality, and competitiveness within a tight market.

This article explores the various ways high-speed quilting machines streamline production, the advantages they offer, and how manufacturers can optimize these machines to their fullest potential.

Understanding High-Speed Mattress Quilting Machines

What Are High-Speed Quilting Machines?

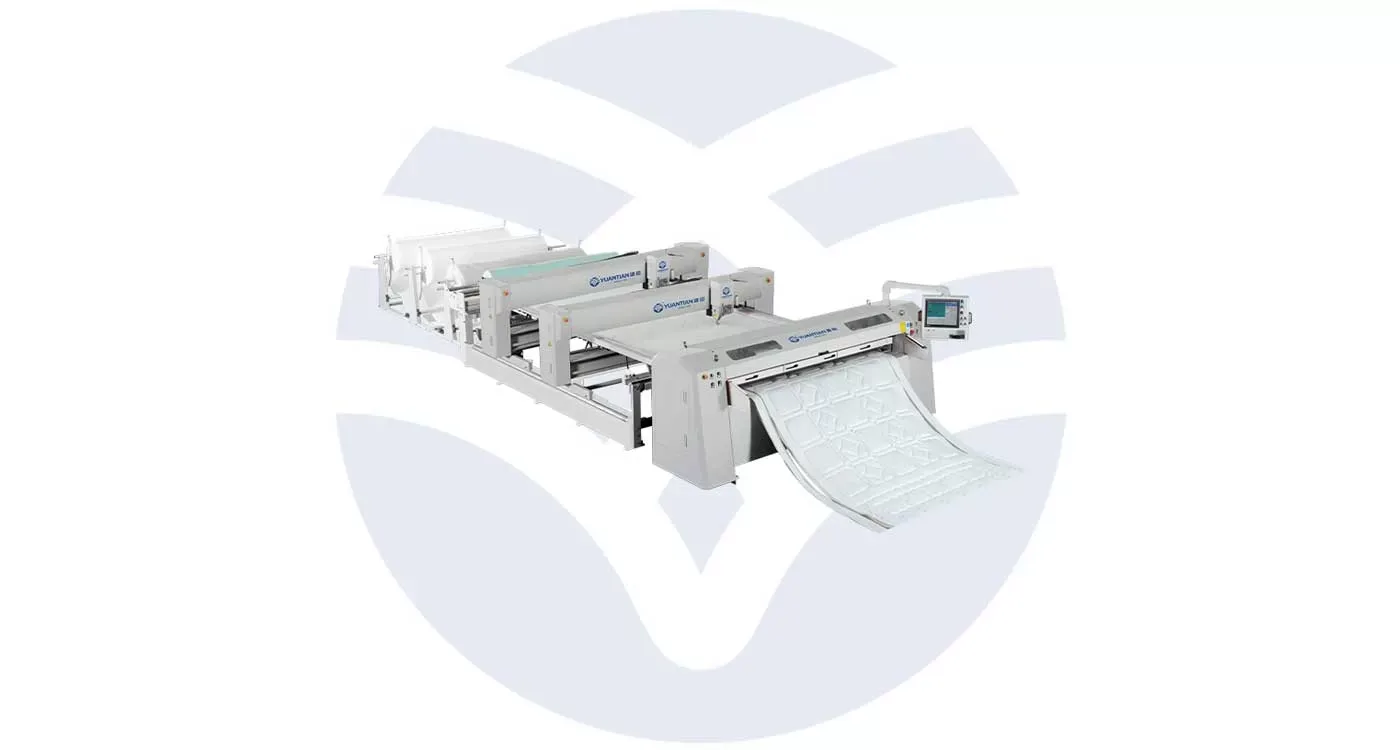

High-speed mattress quilting machines are specific types of machinery developed to stitch layers of fabrics, padding, and foam together in an attempt to create the top quilted layer of a mattress.

High-speed quilting machines are automated, can work continuously, and are designed to be able to work with a wide range of materials. Equipped with a computer-controlled system for the creation of specific stitching patterns, they can do this at great speed and without frequent need for any personal changes. These machines make the product being processed quite consistent.

Key Features of High-Speed Quilting Machines

The modern high-speed quilting machines boast of many features distinguishing them from earlier generations. These include, among others:

Advanced Computer-Controlled Systems: Most high-speed quilting machines have software that allows manufacturers to upload and alter stitching patterns with much ease. This flexibility enables the manufacturer to vary their designs as diversely as possible without having to perform tedious physical adjustments.

Automatic Thread Trimming and Lubrication: Most machines feature automatic thread trimming and lubrication, which minimizes downtown. Thus, the operation becomes smooth and hassle-free. Multiple Needles: In most high-speed machines, there is a configuration where several needles work together to provide stitches at faster speeds over a greater area. This is just right for large mattress panels.

Durable Build for High-Speed Operation: The high-speed machines are designed to meet the challenge of unending high speed wherein structural frames and quality components have reduced wear and tear due to increased usage.

The Impact of High-Speed Quilting Machines on Production Efficiency

Faster Production Cycles

The ability to reduce production cycles by a big margin is one of the major advantages of high speed quilting machines. Quilting is considered to be a very labor-intensive process with the operator controlling the speed at which the stitching is done along with the positioning of the fabric layers, hence frequent adjustments.

The steps mentioned above are automated in high-speed machines, which allow the manufacturers to complete the process much sooner than ever before. Indeed, some machines could produce up to 400 quilted panels per hour compared to 50-100 panels on a standard machine.

Consistency and Precision in Quilting Patterns

Consistency is key to mattress manufacturers. Any amount of inconsistency will make all the difference in product quality and may even result in dissatisfaction among the clients. The high-speed quilting machines have specific stitching patterns across the panels, making the products always consistent in their quality.

The computer-controlled mechanism in these machines ensures minimum human error, further enhancing their consistency in quality. This factor also plays a significant role in the case of high-end mattress brands, as customers will expect an impeccable craft.

Financial Benefits of Investing in High-Speed Quilting Machines

Reduced Labor Costs

While the initial investment in high-speed quilting machines is abnormally high, they yield appreciable labor cost savings. Traditional quilting relies on skilled operators to run the machines, perform adjustments, and supervise the process for quality.

With such high-speed machines, the element of human intervention is very low, thus allowing manufacturers to utilize labor elsewhere in the production process or even cut down on labor without compromising output. Automation with such machines can enable manufacturers to sustain production at the same level irrespective of fluctuating labor availability.

Less Material Waste

Another economic advantage of high-speed quilting machines is reduced material waste. Because these machines are so accurate, each quilted panel is manufactured to exacting standards, greatly reducing the opportunity for mistakes that result in wasted material. That of course equates to material savings for the manufacturers, something that really adds up over time in terms of the bottom line. Additionally, it reduces waste, which makes the production process more sustainable, and that is important to a growing number of consumers.

Leveraging Technology for Enhanced Machine Performance

Using IoT for Predictive Maintenance

Most manufacturers are incorporating high-speed quilting machines with Internet of Things (IoT) technologies that ensure full benefits are realized. IoT sensors installed in the machine enable predictive maintenance, where a manufacturer monitors real-time machine performance, detects any potential problems before their actual occurrence and halting of production, and schedules maintenance at optimal times. This minimizes unexpected breakdowns, reducing costly repairs while maintaining your machines’ smooth running.

Advanced Software for Customizable Patterns

High-speed quilting machines can normally be interfaced with advanced software, which enables manufacturers to personalize the stitching patterns with ease. New designs can be uploaded electronically to give a quick response in case of a change in consumer preference or seasonal variation, which would otherwise involve the manual reconfiguration of the machine. This feature is particularly beneficial for brands that want to introduce distinctive, eye-catching mattress patterns as part of their product differentiator in the market.

Implementing Best Practices for Maximum Efficiency

Regular Training and Upskilling of Operators

Even though high-speed quilting machines reduce the need for manual operation, the operators need to be trained well enough anyway. Basic notions of how the machine works and how one might troubleshoot and manage the software in control of the machine are necessary so that when a problem arises during production, one would correctly deal with it. Upskilling one’s employees to work with more new technologies increases overall productivity and might even lead to better job satisfaction since the workers may feel more competent and important.

Adopting Lean Manufacturing Techniques

Integrating high-speed quilting machines with lean manufacturing methodologies will further enhance this production process. Lean manufacturing focuses on waste reduction, smoothing workflow, and eliminating unnecessary steps, which augments the functionality of high-speed quilting machines. This collaboration thus allows for a smoother, integrated production process that minimizes unnecessary costs and maximizes productivity.

Conclusion

High-speed mattress quilting machines are transforming the mattress manufacturing industry by drastically reducing production time, improving product quality, and enhancing operational efficiency. Although the initial investment is considerable, the benefits, including reduced labor costs, increased output, and consistent quality, make these machines an attractive option for manufacturers looking to stay competitive.

Связанные с ними товары