- Home » Precision and Speed: The Benefits of Mattress Quilting Machines

In the world of mattress manufacturing, technology has revolutionized the way we create comfortable and durable products. One significant advancement is the development of mattress quilting machines.

These machines are designed to stitch layers of fabric and padding together, creating quilted patterns that are both aesthetically pleasing and functionally beneficial. The precision and speed offered by these machines have transformed the mattress industry, making it possible to produce high-quality products at an unprecedented rate.

The Role of Quilting in Mattress Manufacturing

Enhancing Comfort and Durability

Mattress manufacturing uses quilting extensively in its process. It is a process where all the various fabrics and pad layers are sewn together, so the weight is kept equally distributed, and an extra soft layer is created.

In addition to aesthetic value, quilted designs work as boosters to the integrity of structure, thus, the stitching holds the layers together firmly in place and avoids shifting so that a mattress will never change its shape.

Types of Quilted Patterns

Mattress quilting machines can make a wide range of patterns, each with their own advantages. Some common ones are diamond, wave, and geometric designs. These do not solely exist to enhance the look of the mattress but actually contribute to the functionality of the same as well.

For example, some patterns would ensure that some places on the mattress receive instant extra support exactly where really necessary to assure a comfortable sleep and reward the owner with more rest.

Advantages of Using Quilting Machines

Precision in Stitching

Among the important benefits of quilting mattress machines is accuracy. High-tech features in mattress quilting machines enable them to stitch with accuracy.

Good precision guarantees stitch placement that is correct, which maintains the quality of the pattern while at the same time enhancing mattress durability due to quilting. Manually, it would be quite difficult to reach this level of accuracy since much inconsistency in results would be brought about by human error.

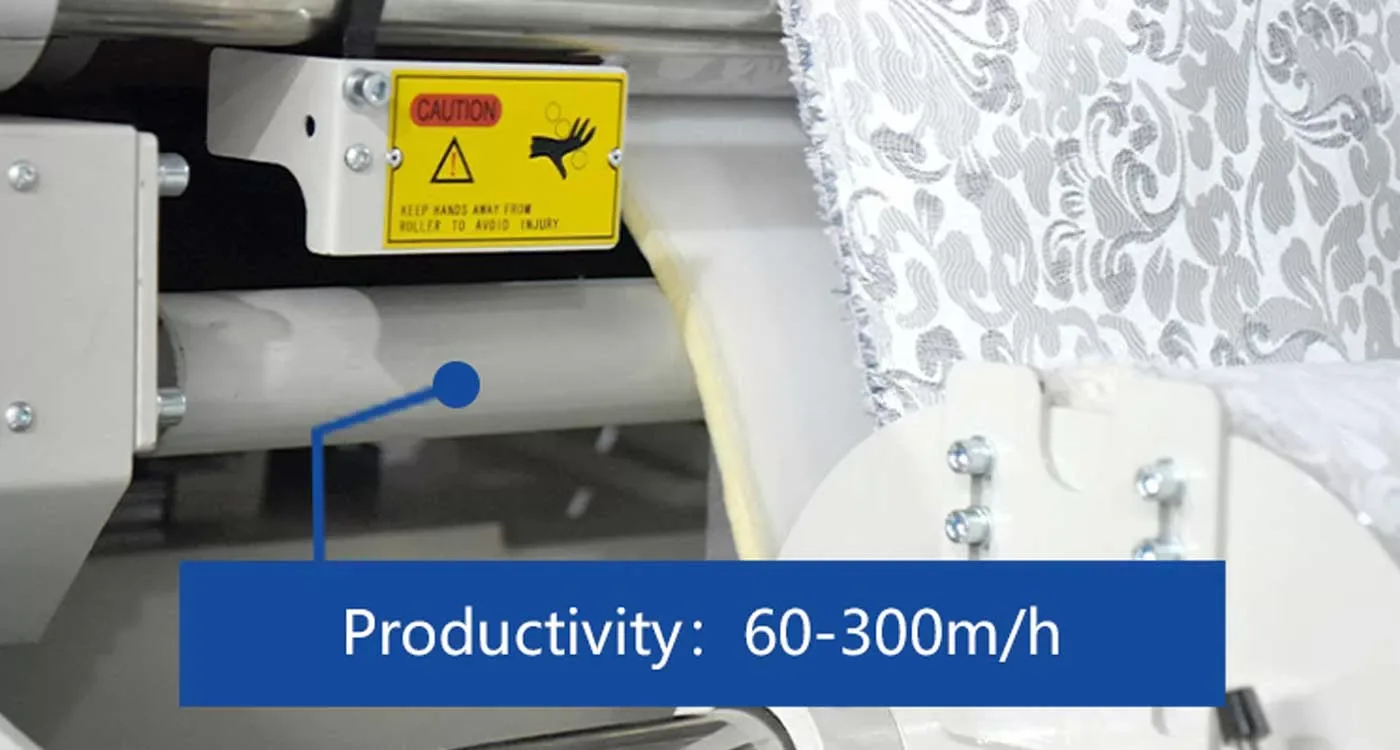

Speed and Efficiency

One of the other major advantages of using mattress quilting machines is the speed of the overall process. One can run mattress quilting machines at very high speeds, stitching large sections of fabric together in a fraction of the time it would take by hand.

This greatly boosts productivity, thus increasing rates of production in order to meet the demand for high-quality mattresses. It is worth noting that the speed at which the machines work in the stitching process does not in any way compromise the quality so that every mattress will be of standard quality.

Consistency in Production

Consistency is paramount in mattress manufacturing. Quilting machines do an excellent job by providing every mattress manufactured with the same quality, uniform stitching, and alignment of patterns. This holds the reputation of the brand where the customers are satisfied.

The variability of results that occurs with manual labor is eliminated through the use of automated machines, which ensure that each product made conforms exactly to specification.

Technological Innovations in Quilting Machines

Computerized Control Systems

Modern mat quilting machines are so designed with control levels for computers. The minute control of the stitching processes and formation of designs is allowed, therefore allowing relative ease to form designs.

On the other hand, the operator feeds quantitative design parameters to the machine, which then accurately follows the instructions. This technology improves not only the quality of the quilts but also eases designing for varied mattresses.

Multi-Needle Capabilities

Most of the quilting machines are multi-needle, allowing sewing in multiple rows in one pass. This not only increases the speed of the quilting process but also speeds up larger mattresses. Large-scale mattress manufacturers prefer multi-needle machines because they need to produce volumes within the shortest time possible.

Integration with Other Manufacturing Processes

Advanced quilting machines can easily be grafted into the cutting and assembly manufacturing processes. Similar integration develops the whole production setup which requires less interaction by hand and ensures the least probability of error. Therefore, through automation for several production stages, a high level of efficiency and quality assurance can be obtained.

Impact on the Mattresses Industry

Increased Production Capacity

Quilting machines have greatly improved in terms of speed and efficiency, and this has translated into increased production capacity in the mattress industry. These faster machines enable companies to make more within less time.

Therefore, they are capable of scaling operations to meet market demand more effectively. In a competitive market where timely delivery and availability matter, this additional capacity is very important.

Cost Savings

Embossing is another place where manufacturers save money from the increased efficiency of automation. While the cost of the initial investment in quilting machines may seem expensive, the increased efficiency and attaining a balanced cost will emerge in the end.

With less manual labor needed, manipulations necessary, and eventually achieved, the manufacturer will be in an increased position to make more profit margins, lower the cost of operations, and therefore save money.

Improved Product Quality

The precision and consistency provided by quilting machines warrant enhanced product quality. Properly quilted mattresses are more durable and comfortable, ultimately leading to increased customer satisfaction. More customer satisfaction tends to increase the likelihood of better online reviews and/or consumer loyalty and, thus, the overall success of the producer.

Future Trends in Mattress Quilting

Advances in Automation

With further advancement of technology, it can be expected that the quilting machine for mattresses will also be modified. Automation would increase while the machines get more sophisticated and capable of taking in very intricate commands.

The same can be said about the advancement in artificial intelligence and machine learning, this would mean the machines are capable of adapting to different sorts of materials and patterns to increase the efficiency level.

Sustainability Considerations

For instance, sustainability has become a critical concern in all manufacturing sectors, including mattresses. On the other hand, future quilting machines could be built with a focus on energy efficiency, significantly impacting the environment. More importance may be placed on sustainable materials that are quilted, using an increasing demand for eco-friendly products.

Customization and Personalization

Going forward, the trends associated with customization as well as personalization will continue and gain importance for the quilting machines. And more and more, manufacturers will offer personalized mattresses attuned to individuals, customized to draw quilting patterns. This flexibility and creativity will be allowed by progress in the technology of the machines.

Conclusion

Mattress quilting machines have transformed the mattress manufacturing industry by offering unparalleled precision, speed, and consistency. These machines have enabled manufacturers to produce high-quality mattresses efficiently, meeting market demand and improving customer satisfaction.

As technology continues to evolve, we can expect further advancements in quilting machines, driving innovation and growth in the industry. The benefits of these machines are clear, making them an essential component of modern mattress manufacturing.

Связанные с ними товары