- Home » Optimizing Spring Production: Key Benefits of High-Speed Mattress Spring Machines

In mattress manufacturing, efficiency and quality of spring production become the top priority. The incorporation of high-speed mattress spring machines into manufacturing processes appears to have become the major component of optimizing processes, raising the quality of the products, and improving the potentiality for superior results throughout the operations. This passage delves into the significant benefits of utilizing these advanced machines, highlighting their impact on production speed, product consistency, and cost-effectiveness.

The Evolution of Mattress Spring Machines

Early Spring Production Methods

Historically, mattress spring making has been a very labor-intensive process. Manufacturing and assembling the actual springs required a lot of time and labor. The spring was usually handmade or assembled using crude machinery, which generated a lot of variability in quality and even prevented efficiency in production.

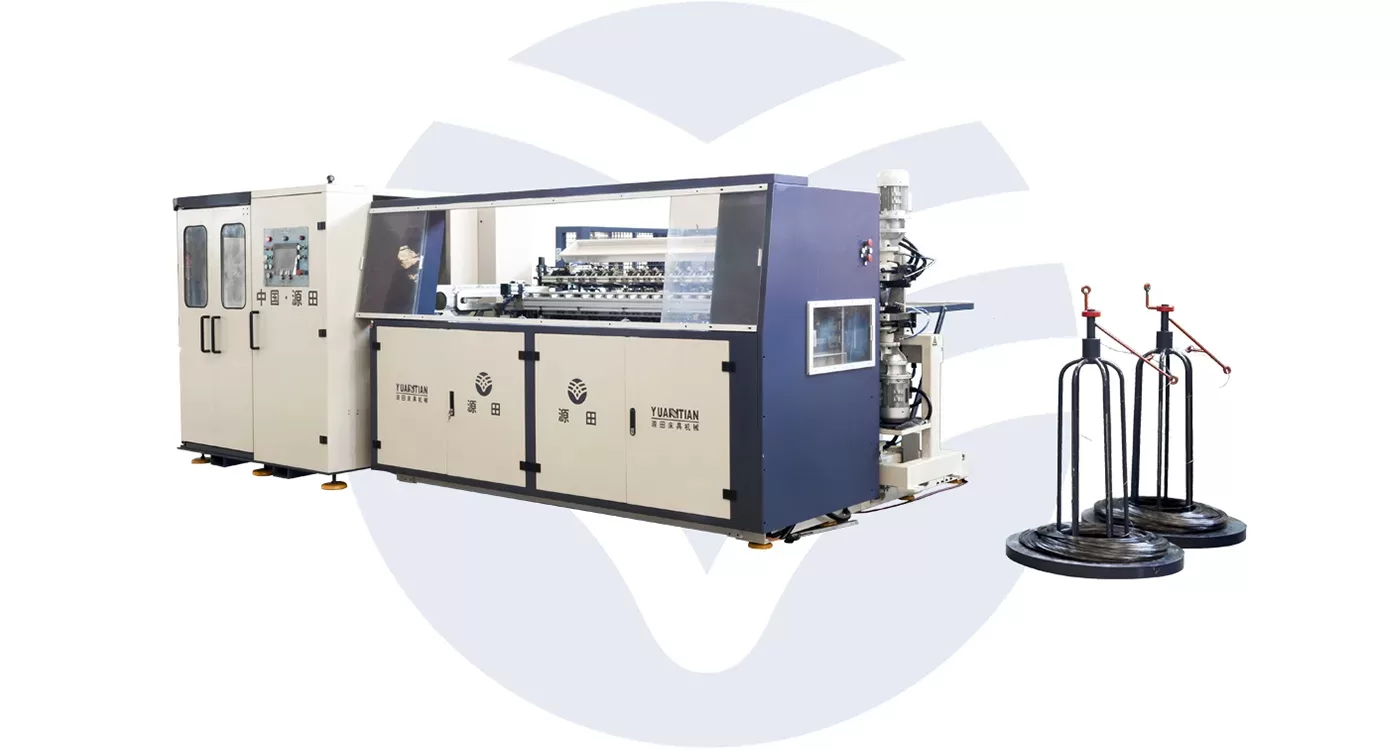

Introduction of High-Speed Machines

The invention of high-speed mattress spring machinery marked a whole revolution in the industry. Advanced technology upgrades machines with more automation, simplifying and streamlining the production process. These high-speed machines produce the product much faster compared to other means and manage to overcome many of the drawbacks that come with previous methodologies.

Key Benefits of High-Speed Mattress Spring Machines

Increased Production Speed

Probably the most striking benefit of high-speed mattress spring machines is that they really accelerate the production process. These machines operate much more quickly compared to other traditional ways of operating, thus enabling manufacturers to produce more springs within a shorter period of time. Investing in high-speed mattress spring machines can lead to significant cost savings and economic benefits for manufacturers.

Impact on Production Efficiency

This again means that increased production speed will directly translate into improved production efficiency. As a result, manufacturers can then meet higher levels of demand and respond quickly to market trends. This efficiency is quite critical in retaining competitiveness within this fast-moving industry where meeting customer expectations is key.

Reduction in Lead Times

High-speed machines reduce lead times, hence allowing quicker turnarounds in orders. This advantage is important, especially for those industries where fast delivery and response are a concern for customers.

Consistency and Quality Control

High-speed mattress spring machines ensure that the quality and consistency of production are much better compared to manual production. Such machines are engineered to make springs of correct dimension with uniform quality, which eliminates variation in the performance and durability of the finished product.

Precision Engineering

High-speed machines are equipped with advanced engineering features that ensure precise spring dimensions and consistent coil tension. This precision reduces the likelihood of defects and ensures that each spring meets the required specifications.

Enhanced Quality Assurance

Real-time quality control systems operate on high-speed machines, which automatically check the production process. Such automated systems prevent deviation and modify any defective one immediately, hence only those springs that pass the quality are forwarded for further processing.

Reduced Labour Costs

With high-speed machines’ automation capabilities, fewer personnel would be needed, which in turn means lesser labor costs. In the production process itself, fewer operators would be needed, thereby reducing payroll and giving staff more time to devote to other critical functions.

Lower Production Costs

In addition to the labor savings, high-speed machines contribute to lower production costs due to better material utilization and reduced waste. The accuracy and speed of these machines translate to a situation where materials are utilized more efficiently to drive down the cost of overall production.

Increased Profit Margins

The increase in production speed, coupled with reduced labor costs and lower costs of production, culminates in higher profit margins. Manufacturers are able to obtain more profitability by optimizing production efficiency in addition to minimizing operational expenses.

Versatility in Spring Types

Pocket springs, Bonnell springs, and continuous coil springs are just some of the options that modern high-speed machines are prepared to work with. Consequently, this opens up the possibility of producing a number of mattress types on the same machine. High-speed mattress spring machines offer a high degree of flexibility and adaptability, making them suitable for various production needs.

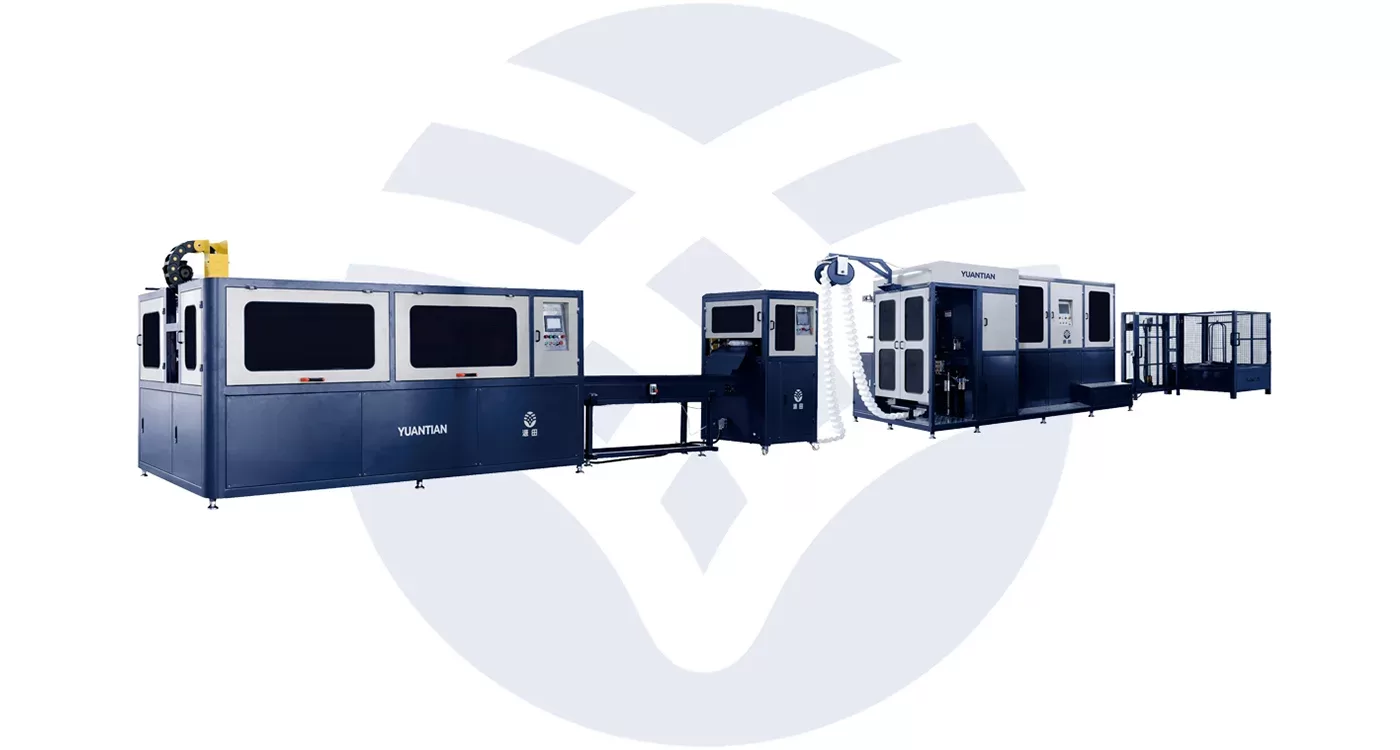

Easy Integration with Existing Systems

The high-speed machines can be integrated with existing automated assembly lines, quality control systems, and other production systems. Integration with other high-level production systems enhances general production efficiency and allows the manufacturer to use their current infrastructure.

Technological Advancements and Innovation

The continuous improvement in the technological advancement of high-speed mattress spring machinery brings along new features and capabilities to enhance efficiency in the production process.

Advanced Automation

Advanced robotic handling and sorting of springs automatically further reduce manual involvement in the production process. Such changes bring significant improvement in operational efficiency and drastically reduce the probability of human error.

Smart Control Systems

High-speed machines with intelligent control systems always provide crucial data and analytics to the manufacturer in real time. The system makes it possible for manufacturers to monitor production performance, identify potential problems, and make data-driven decisions in order to optimize production processes.

Reduced Energy Consumption

High-speed machines are energy-efficient and consume less energy compared to older, less effective machines. The reduction in energy consumption saves the business operating costs and provides a reduced environmental footprint.

Decreased Waste Generation

The adoption of high-speed mattress spring machines also bodes well in terms of environmental sustainability. High-speed machines result in fewer material wastes due to the precision and efficiency of the machines resulting in real work without defects. That reduces the environmental impacts associated with waste management processes.

Conclusion

High-speed mattress spring machines are a quantum leap in the mattress manufacturing industry. Advantages inherent in their use run the gamut from higher production speeds to consistency, cost-effectiveness, and flexibility, thus, they constitute something worth investing in by manufacturers keen on streamlining the production processes. As technology continues to evolve, these machines will undoubtedly play a crucial role in shaping the future of mattress spring production, driving further innovations, and contributing to a more efficient and sustainable industry.

Связанные с ними товары