- Home » Mattress Flanging Machines: Why Every Manufacturer Needs One

Efficiency and quality are the major leeways in the rather dynamic setting of the mattress manufacturing industry. Mattress companies are always seeking ways to increase efficiency and produce a better-quality product in a shorter time. One essential piece of machinery that can significantly enhance production efficiency and product durability is the mattress flanging machine.

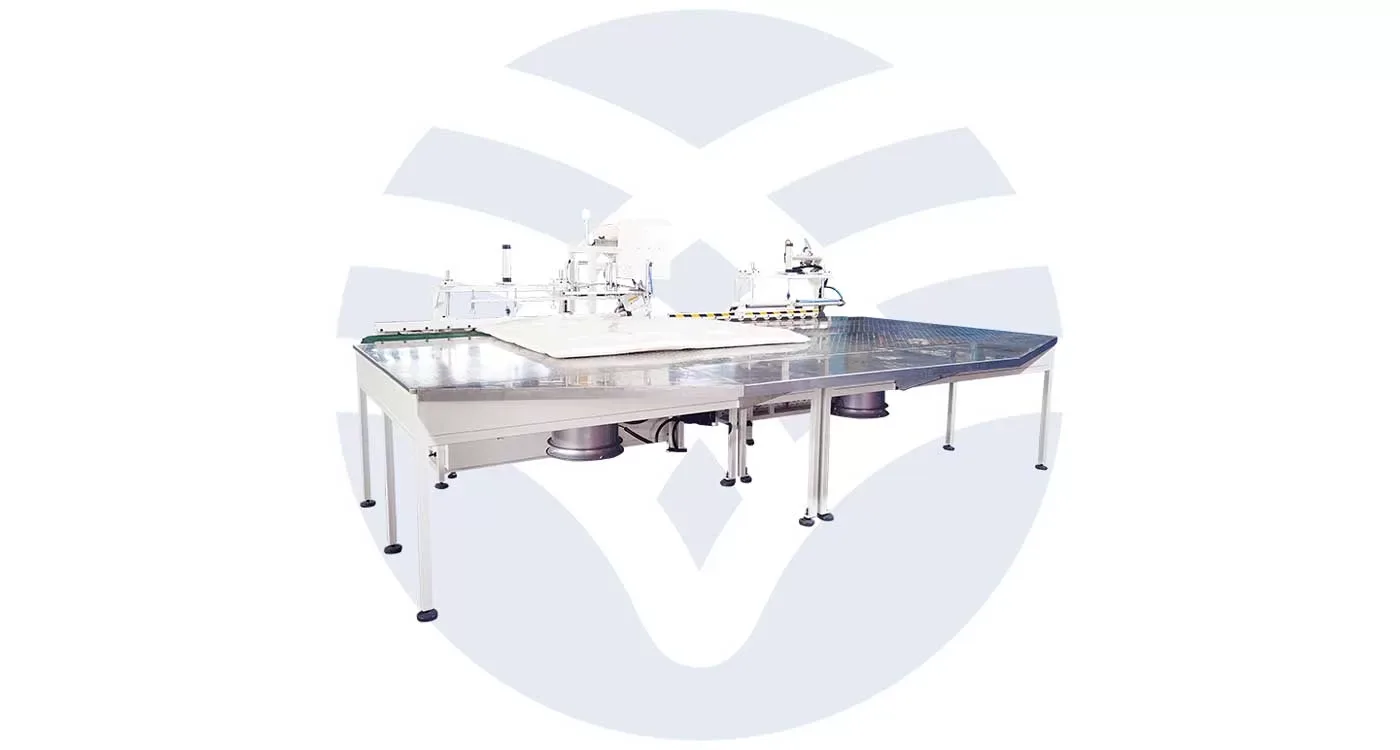

These machines automate the process of attaching the quilted top and bottom panels to the mattress border, a step that is crucial in mattress assembly. This article delves into the workings of mattress flanging machines, their benefits, and how they can help manufacturers achieve a competitive edge.

Understanding Mattress Flanging Machines

What is a Mattress Flanging Machine?

A mattress flanging machine falls under a special category of sewing machine employed in the process of mattress production, where mattress panels are attached to its border, thus, this attachment is seamless for these components. The reason why this flanging process is so crucial with regard to this mattress production is that it ensures mattresses will last and their layers do not shift over time.

Flanging is a delicate task, as the stitching needs to be both strong and flexible enough to handle weight and movement without tearing or coming undone. Unlike manual methods, flanging machines deliver precision, consistency, and speed, which are critical for high-quality mattress production.

Key Features of Mattress Flanging Machines

Mattress flanging machines possess quite a number of features that make them vital in a production setting:

- Automated Stitching System: These machines stitch the panels to borders automatically without human intervention to avoid any chance of human error.

- High-Speed Operation: The flanging machines are designed to work at high speed, reducing the production time by stitching hundreds of stitches per minute.

- Adjustable Settings: The manufacturer can adjust stitch length, tension, and speed in the flanging machines, which helps the manufacturer work with different mattress designs and thicknesses.

- Edge Control and Guide Mechanisms: Most of the time, flanging machines are designed with guide mechanisms that keep the fabric in its place to have even and clean edges for consistent stitching.

Benefits of Using a Mattress Flanging Machine

Enhanced Production Efficiency

Among all the advantages that a mattress flanging machine offers, the most major one is the increase in the production at hand. Conventionally, flanging relies on skilled labor for manually attaching the panels and borders in a very time-consuming and laborious manner.

Flanging machines make this process automated, thus allowing manufacturers to carry out the same work in only a fraction of the time required. To manufacturers with high volumes, such a cut in production time directly translates into cost savings and increased output to meet the rising consumer demands.

Improved Consistency and Quality

This indeed is consistency, both in durability and aesthetic appeal, which is very important when it comes to manufacturing mattresses. Consistency can be a hard factor to achieve with hand-stitching, since it is different with every operator, thus, every mattress can be somewhat different.

However, with one flanging machine, all mattresses can be stitched similarly and fall under the same category of quality for manufacturers. This not only ensures consistency in adding to the structural integrity of the mattress but also enhances aesthetic quality, a vital component in a competitive market where the consumer looks for beauty even on a product meant for sleeping.

Reduced Labor Costs

Since flanging machines automate an important part of assembling a mattress, they reduce the demand for human labor in this particular area. This enables the manufacturing company to free labor and allocate it to other productive parts, where skills are utilized better, such as quality inspections or finishes.

Additionally, lower labor pushes the advantage bar even higher with reduced overall production costs, one very important benefit to tight-budget manufacturers. Over time, cost savings from reduced labor expenditures can balance out the initial investment in flanging machinery.

Technological Advancements in Mattress Flanging Machines

Integration with Computer-Controlled Systems

Modern mattress flanging machines may also be combined with computer-controlled systems, which permit refined control of stitching patterns and speeds, together with thread tension.

Not only does automation of this nature bring remarkable improvements in efficiency, but it also gives the manufacturer increased flexibility in easily adjusting setting changes as the mattress specifications call for it. Mattresses, for example, that are thicker or with added layers, may need modifications in stitch length and tension that computer-controlled systems can manage with only a very small loss of time.

Enhanced Safety Features

As with all heavy machinery, safety is a top concern. In modern times, improvements in flanging machines integrate automatic shut-off systems, an emergency stop button, and a needle guard to make the operation much safer around the machines, limiting accidents and serious injuries. This would mean that manufacturers have a much safer workplace, and they would have a reduced liability.

IoT and Real-Time Monitoring Capabilities

With IoT integration in flanging machines, real-time monitoring has enabled manufacturers to trace the performance and defects of their machines before any occurrence of downtime. In addition, sensors may monitor speed, needle tension, and stitch quality for further analysis.

Therefore, this will help manufacturers in finding an area where preventive maintenance might be required. This is predictive maintenance, therefore reducing the chances of occasional breakdowns and assuring further flow smoothing at production.

Maximizing the Potential of Mattress Flanging Machines

Operator Training and Skill Development

Even though the flanging machine automates much of the processes, skilled operators are yet needed to realize maximum performance. Proper training enables operators to effectively handle minor adjustments, troubleshoot problems, and maintain the machine. Moreover, operators who are acquainted with the machine’s features will alter settings to fit various mattress designs, hence flexibility and adaptability on production.

Regular Maintenance and Upkeep

The manufacturers can care by extending the life and efficiency of the flanging machines by offering routine maintenance that involves routine cleaning, lubrication, and inspections so as to ensure that all parts are performing to their fullest extent.

Most manufacturers also invest in a preventive maintenance program wherein trained technicians regularly inspect the machine and replace worn parts before they start causing problems. These various maintenance practices tend to extend the lifespan of the machine with an increased return on investment over a long period of time.

Conclusion

In today’s competitive environment for mattress manufacturing, investment in a mattress flanging machine is no longer an option but an indispensable tool. It improves efficiency, consistency, and cost impetus that benefits a manufacturer in order to satisfy consumer demand at all times and with quality assurance. With supplements of advanced technologies like computer-controlled systems and IoT capabilities, modern flanging machines are now much more versatile, more reliable, and easier to integrate into production lines than ever before.

By investing in mattress flanging machines and implementing best practices in maintenance and operator training, manufacturers can improve their production processes, reduce costs, and ensure they stay ahead in a rapidly evolving market.

Связанные с ними товары