- Home » Mattress Flanging Machine vs. Mattress Tape Edge Machine: Key Differences

Mattress manufacturing requires several special machines for stitching, edging, and sewing, among other processes. Two of the more important machines in the mattress industry include the mattress flanging machine and the mattress tape edge machine. Much as they are used complementarily in mattress production, they have different functions, designs, and applications.

Understanding the differences between these machines is crucial for anyone involved in mattress production, as it affects the quality, efficiency, and cost-effectiveness of manufacturing.

What is a Mattress Flanging Machine?

A mattress flanging machine serves mainly to attach the flanges onto the mattress panels, and normally it is for preparing them for later processes such as tape edging or quilting. The strips of fabric sewn onto the edges of the mattress panel are called flanges, whose main job is to connect both the top and bottom panels to the borders of the mattress to give the mattress its structural integrity.

How the Mattress Flanging Machine Works

A mattress flanging machine is primarily used for attaching the flanges to the mattress panels, typically to prepare them for later processes, such as tape edging or quilting. Flanges are strips of fabric sewn onto the mattress panel edges, and their main role is to connect the top and bottom panels to the mattress borders, providing structural integrity to the mattress.

Key Features of Mattress Flanging Machines

Multiple Needles: Flanging machines typically have multiple needles to ensure the mattress’s edges are sewn evenly and with high precision.

Adjustable to Various Materials: These machines can be adjusted to make mattresses from different types of materials-cotton, foam, or memory foam. This is beneficial in that the same machine can work on a wide range of materials used in the production of mattresses.

Stitching Patterns: The stitching patterns can also be varied in flanging machines. This provides an avenue for producers to select which stitch pattern best suits the particular products being produced.

Automation: Most of the flanging machines today are highly automated with conveyor systems and automatic thread cutting, making the process a lot easier.

In essence, the flanging machine is the main machinery in the primary stages of mattress assembly. It ensures the strongest base or foundation that would then provide the needed support during the final stitching and edging processes.

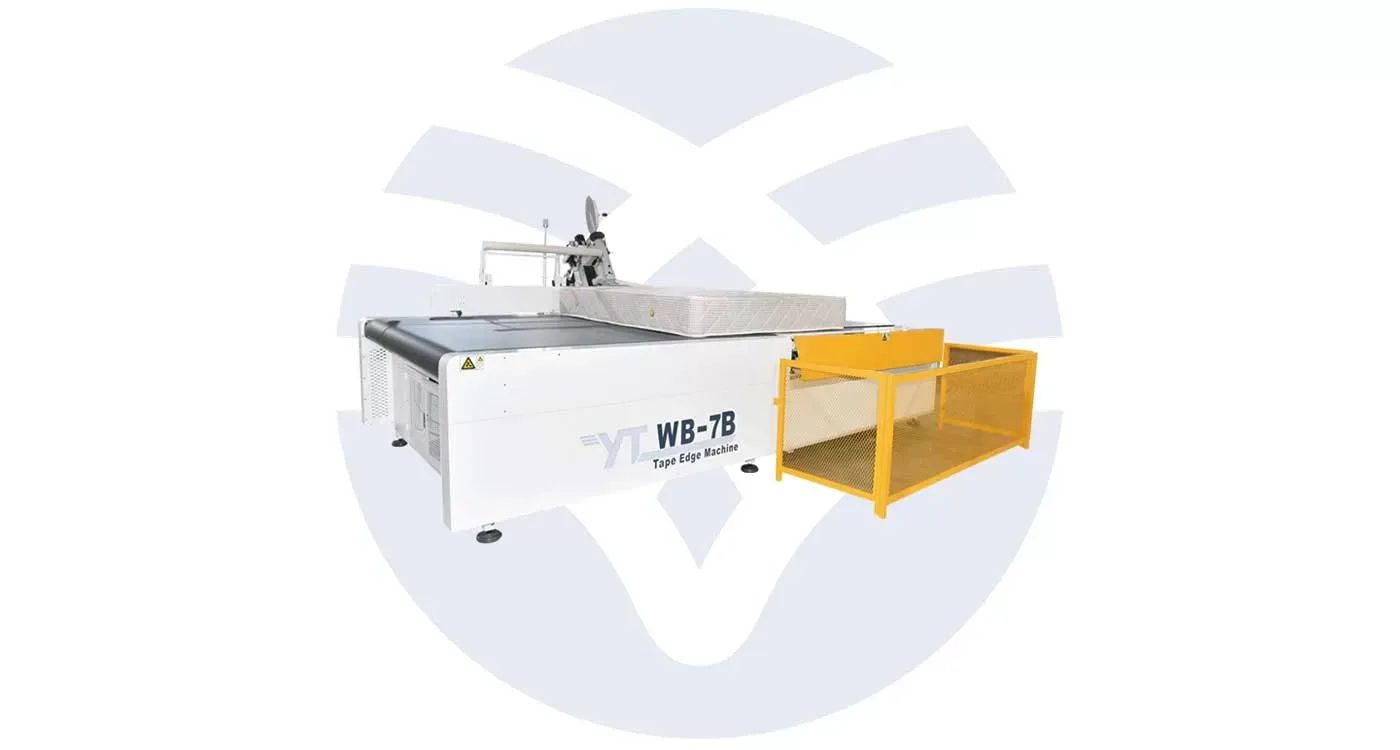

What is a Mattress Tape Edge Machine?

The mattress tape edge machine is used to stitch the tape along the edges of the mattress once the panels and borders are assembled. It finishes the view of the mattress by covering and sealing the outer edges. It usually consists of a hard-wearing strip of fabric applied on the tape that mostly binds the top and bottom panels to the side border, covering seams and giving the mattress a neat, professional finish.

How the Mattress Tape Edge Machine Works

The mattress tape edge machine sews binding tape around the total circumference of the mattress to ensure that all layers are securely fastened and sealed. It generally comprises one moving sewing head and a platform that rotates the mattress. The operator controls the mattress while the machine performs the stitching of the tape along the edge. The sewing mechanism is adjusted for various thicknesses to provide consistent tension and precision.

Key Features of Mattress Tape Edge Machines

Flexible Movement: These machines are often mounted on a movable table or platform, allowing the operator to rotate the mattress while stitching the edges.

Variable Speed Control: Most modern tape edge machines have variable speed control so that the operator can adjust the stitching speed according to the materials used and the thickness of various mattresses.

Adjustable Sewing Heads: These machines can be adjusted for various mattress sizes and thicknesses, thus allowing the stitching of mattresses of all types, ranging from very thin mattresses to ultra-thick models.

Versatility: Tape edge machines can place edges stitched on all types of mattresses, be they innerspring, foam, or even hybrid mattresses.

Automation and Semi-Automation Options: Similar to flanging machines, most tape edge machines boast automation features that further enhance production.

The tape edge machine is essentially the last step in the mattress production process, ensuring that the mattress has a clean, professional finish and that all seams are tightly secured.

Differences in Functionality

While both machines serve in the mattress production process, they have different functionalities:

Purpose

The flanging machine serves earlier in the production line, attaching the flange around the mattress panels, mainly to connect the top and bottom panels to the side borders.

The tape edge machine serves at the last stages of mattress production, sewing a binding tape along the edges, thereby sealing the top, bottom, and side borders of the mattress for a finished look.

Position in the Production Line

The flanging machine is one of the initial machines used in the assembly process, preparing the mattress for edging and quilting.

The tape edge machine is the final machine involved in the production of mattresses, giving it that finished look and completing the structural integrity of the mattress.

Materials Handled

Fabric strips and mattress panels are handled by flanging machines, mostly focusing on the edges of the mattress.

Tape edge machines deal with thicker, more durable binding tapes that enclose and seal the mattress by stitching through multiple layers of fabric, foam, and sometimes springs.

Operational Differences

There are also considerable differences in operation between a mattress flanging machine and a mattress tape edge machine:

Stitching Mechanisms

The stitching required to join the fabric and the flange together is so complex that the job requires the flanging machine to have more than one needle. In contrast, tape edge machines use one-needle mechanisms that stitch along the mattress edge with a great deal of accuracy and consistency.

Automation and Skill Levels

These two machines have options for automation, but the percentage of operator involvement is different. In the case of the flanging machine, most often it can be made more automated, requiring less human guidance once the settings are done. In the case of the tape edge machine, it requires more operator involvement, especially in guiding the mattress on the rotating platform while the correct stitching of the edges is done.

Production Speed and Efficiency

Flanging machines can generally be a bit faster, as they have the easier task of attaching fabric strips to the edges of the mattress. Tape edge machines can be slower since they operate at the final, most sensitive stage of this process, where every edge has to be well-placed and stitched.

Both machines are highly efficient in their respective roles, but the tape edge machine has more impact on the mattress’s visual and structural quality, meaning operators often need to prioritize precision over speed.

Conclusion

Both the mattress flanging machine and the mattress tape edge machine are vital in the production of mattresses, but they serve very different purposes within the line of manufacture. While the flanging machine provides concentration on the foundational stage, making sure the panels are ready for final assembly, the tape edge machine offers a professional look for the mattress.

Связанные с ними товары