- Home » Manual vs. Automatic Mattress Packaging Machines: Pros and Cons

Packaging is a crucial step in the mattress manufacturing process. The right packaging ensures that the product is protected during transport and storage while maintaining its aesthetic appeal for customers. The choice between manual and automatic mattress packaging machines plays a significant role in determining the efficiency, cost-effectiveness, and overall output of the packaging process.

Each type of machine has its advantages and disadvantages, depending on the scale of production, budget, and specific operational requirements. In this article, we will explore the pros and cons of both manual and automatic mattress packaging machines to help manufacturers make an informed decision.

Overview of Mattress Packaging Machines

The Purpose of Mattress Packaging Machines

Mattress packaging machines compress, wrap, and seal mattresses for easy handling, transportation, and storage. It ensures dust, moisture, and physical damage do not come into contact with the mattress when shipping. Packaging also plays a role in maintaining the integrity of a product to ensure it reaches a retailer or a customer’s location in good shape.

There are mainly two types of mattress packaging machines:

Manual Packaging Machines: These machines use intensive operator involvement in packaging. The placing and wrapping of the mattress have to be done manually by the operator, while compression or sealing is aided by the machine.

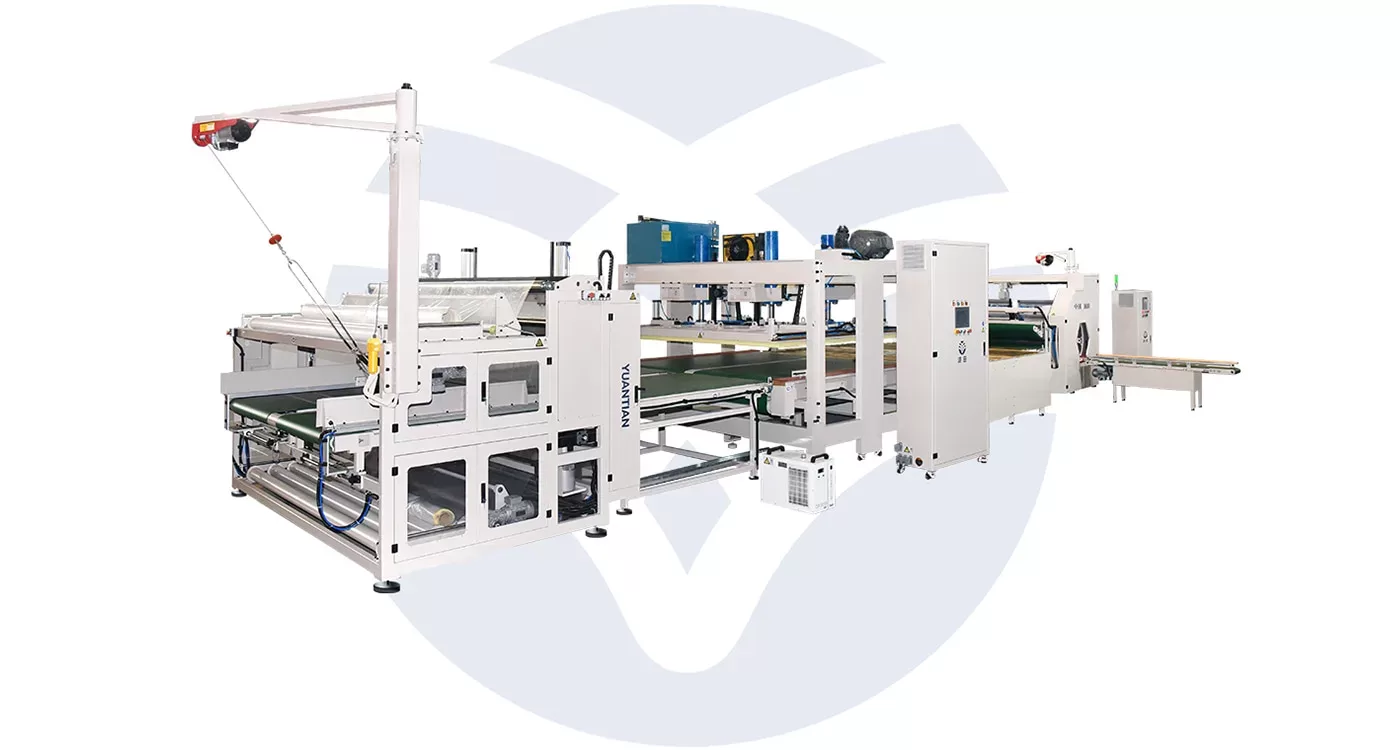

Automatic Packaging Machines: The machine does most of the work in packaging, with minimal operator interference. The mattresses are fed into the machine, which compresses, wraps, and seals them in a completely automated manner.

The choice between these two types depends on various factors such as production volume, workforce availability, and investment capacity.

Manual Mattress Packaging Machines

Pros of Manual Mattress Packaging Machines

One of the major advantages of manual mattress packaging machines is that entry barriers are somewhat low cost. They are much cheaper compared to their automatic counterparts. This makes them very attractive options for small and medium-sized businesses or a manufacturer just starting in business. For companies lacking capital to invest in expensive, automatic machinery, a manual option provides a reasonable alternative through which their packaging needs can be met.

Other benefits of manual machines are their flexibility in packaging sizes and types of mattresses. It is pretty easy for operators to adjust a machine for the accommodation of custom sizes or non-standard mattresses. This will be very helpful for those manufacturers who make a wide range of products or customized mattresses that require different ways of packaging.

With manual machines, operators have more direct control over the packaging process. This can be beneficial when packaging high-end mattresses that require extra care or precision to ensure the product is not damaged during compression or wrapping. Human oversight allows for adjustments to be made in real-time, minimizing errors.

The manual type of packaging machines are much smaller in their build and design compared to automatic machines and take up much less ground space, which is also a very key component for factories with space constraints. These machines are also easier to relocate or modify inside the production line if it’s required.

Cons of Manual Mattress Packaging Machines

However, the disadvantage of manual machines is that the operating speed is a bit slower in comparison to automatic machines. Since most of the processes rely on human labor, the production rates depend on how fast the operators can operate. If there is high demand or large-scale production, the manual machines will probably not be able to keep up with it, therefore, there could be potential bottlenecks in the packaging line.

While the actual purchase price of a manual machine may be less, the long-term labor costs are higher because you need more operators. When the volume of your production is high, the recruitment, training, and maintenance of your staff cost very high and hence make the end product not that cost-effective over time.

Human error in a manual packaging process is most likely to occur. Wrapping, sealing, or compressive inconsistencies are most likely to occur with operators who may be fatigued, distracted, or untrained. This could lead to poorly packaged mattresses that are sure to be highly vulnerable to damage during shipment and may result in customer dissatisfaction and even returns.

With manual machines, operators are more involved physically, increasing the rate of workplace injury considering that the working environment may be repetitive and physically aggressive. Companies operating manual machines have to invest more in safety training and ergonomic solutions to reduce the risk.

Automatic Mattress Packaging Machines

Pros of Automatic Mattress Packaging Machines

Fully automatic machines are made to be efficient, and they can speed up the process of packaging by huge margins. These machines, because of minimum operator interference, can package mattresses at a much higher rate compared to manual machines and are thus ideal for large-scale production. The high output will enable manufacturers to deliver on time, even when deadlines are too tight and demand is high.

Automatic machines deliver consistent results with every cycle, reducing the chances of human error and ensuring uniformity in packaging. This uniformity ensures overall quality in packaging to minimize damage during transport and improves the unboxing experience for the customer. Precision automated sealing seals mattresses properly to protect them from moisture, dust, and other outside elements.

While the initial investment of an automatic machine is higher, after a while it saves drastically on labor costs. In automated packaging lines, few operators are needed to supervise the packaging line. This decreases the amount spent on recruitment, training, and management of staff, hence, automatic machines are cost-effective for long-run companies with high volumes of production.

The application of automatic machines saves man-hours used in a packaging line through manual handling, thereby making the workplace safe. Since the interaction of the operator with the machine is reduced, injury occurrence is also reduced to a minimum. Most automatic machines have built-in safety features including emergency stop buttons, sensors, and protective barriers, making the workplace safer.

Cons of Automatic Mattress Packaging Machines

Of all the disadvantages that stem from the use of automatic machines, perhaps the most outstanding occurs with respect to the cost of such equipment. The machines represent a serious capital investment, not possible in all cases for small- or medium-sized manufacturers. Besides the purchase price, there may also be facility installation training, and modification costs, as machines are larger and technically more complicated.

They usually are targeted for high-volume and standard-sized mattresses. While speed and efficiency may be guaranteed through them, flexibility in packaging non-standard or custom mattresses might not be their strong suit. Changing a machine to run a variety of mattress sizes and shapes often can take more time.

Automatic machines are complicated and usually need constant maintenance in order to work right. If one automatic machine breaks down, the whole packaging process might be held up until repairs are effected. These machines, upon breakdown, may require specialized technicians, which increases the cost even more due to their operation rate or possible loss of production time.

Fully automatic packaging machines are generally much larger than manually operated ones and require a large amount of space. Companies with limited floor space have to do some modifications in the facility or adjust the production line to accommodate an automatic machine, and this could be an added expense.

Choosing the Right Packaging Machine

Factors to Consider

Production Volume: While high-volume manufacturers stand to benefit greatly from their investment in automatic machines due to their speed and efficiency, manual machines remain practical, cost-effective means for small companies or others whose volumes of production are quite lower.

Budget: While budgetary constraints are one of the reasons for choosing manual machines, where a company has the capital to invest in automation, long-term savings on labor and an increase in production capacity justify the buying of automatic machines.

Workforce Availability: With limited availability of staff or high labor costs, companies may have to resort to the use of an automatic machine as an ideal alternative. Those companies that can avail the workforce resources will necessarily go for manual machines in order to maintain cost-effectiveness.

Customization Needs: Depending on whether manufacturing involves a broad range of mattress sizes or custom products, a manufacturer might appreciate the flexibility offered by manual machines. In cases where standardized production runs are possible at large-scale levels, automatic machines prove to be worth investing in.

Conclusion

Both manual and automatic mattress packaging machines have their respective pros and cons, and the best choice depends on the manufacturer’s specific needs. Manual machines offer flexibility and lower initial investment, making them ideal for smaller businesses or those producing custom mattresses. However, they come with higher long-term labor costs and slower production speeds.

On the other hand, automatic machines provide speed, consistency, and reduced labor expenses but require a higher upfront cost and more space. Ultimately, the decision should be based on production requirements, budget constraints, and long-term operational goals.

Связанные с ними товары