- Home » Maintenance Tips for Long-Lasting Mattress Tape Edge Machines

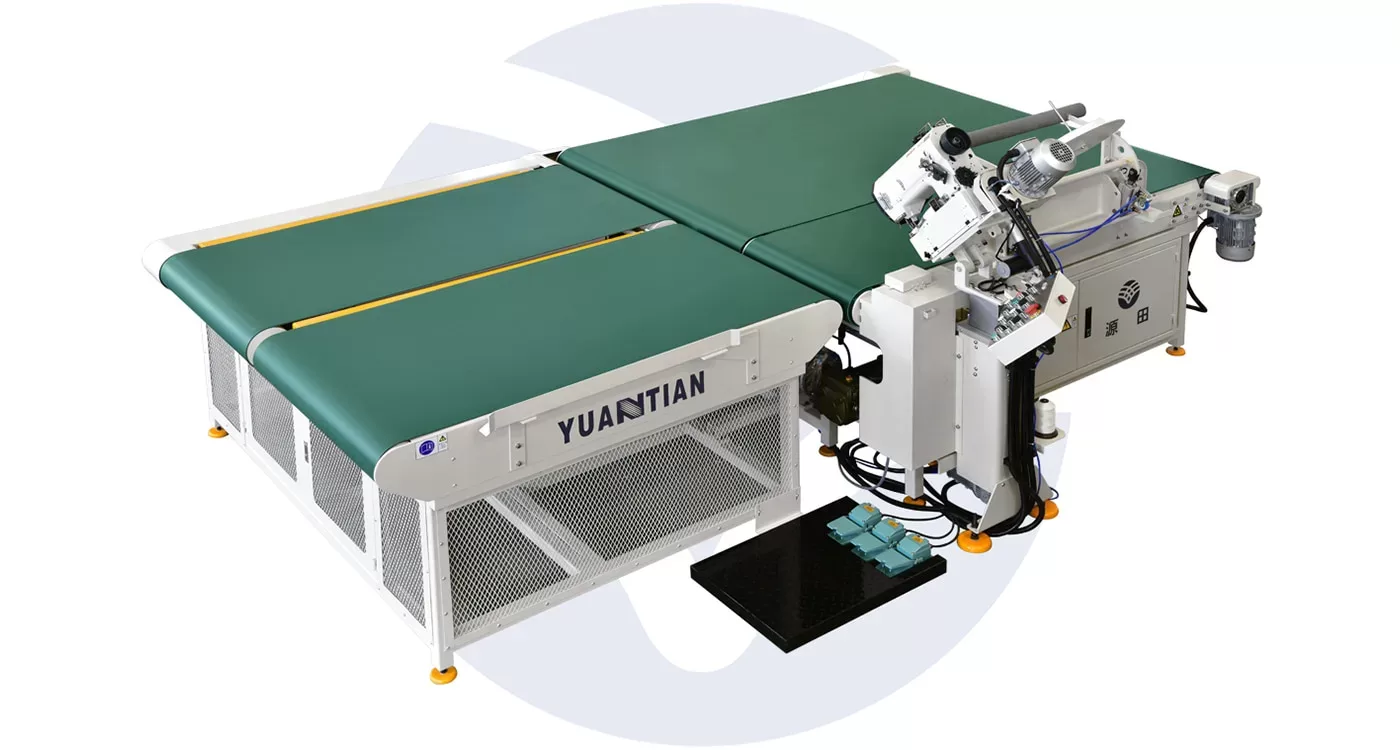

Mattress tape edge machines are important for producing quality mattresses. These machines seal the fabric with the finishing edge tape, giving the mattress a professional look and finish. Since this is one of the most important final touches in manufacturing, maintaining the good condition of these tape edge machines should be ensured against production delays, quality of the product, and extending the life of the equipment.

This guide will outline the best practices in maintaining mattress tape edge machines, categorized as preventive maintenance, operational considerations, and troubleshooting.

Importance of Regular Maintenance

Mattress tape edge machines must be serviced regularly to ensure that they function efficiently and without any breakdowns. As they are involved in a critical part of mattress manufacturing, small problems may as well translate to operational delays and increased downtime. Due to the heavy usage they normally receive, taking a proactive maintenance approach will avoid major problems and reduce repair costs with extended machine life.

Preventive Maintenance: A Must

Preventive maintenance is a regular inspection and servicing of the machine in order to avoid mechanical failure. Possible problems are prevented before they would be huge by adhering to the routine schedule of usually checking up and repairing.

Preventive maintenance includes:

Lubrication: Proper lubrication of all moving parts prevents wear and tear because friction is greatly reduced, hence decreasing the likelihood of part failure.

Cleaning: Where dust, lint, and debris are cleaned from the machine daily to prevent such contaminants from entering the mechanisms of the machine to cause malfunction.

Belt and Chain Inspection: The belts and chains should be inspected for their wear and tension. Over a period of time, these factory-fresh components may be stretched or frayed, misaligning or malfunctioning the machine.

Needle Checking: It is necessary to periodically check the needle since mattress tape edge machines use so many thick and heavy fabrics. A bad needle could cause incorrect stitching or further damage to the machine.

Regular preventive maintenance helps prevent costly breakdowns and allows the equipment to continue running smoothly and produce high-quality mattresses time after time.

Operational Best Practices

In addition to preventive maintenance, how the machine is operated on a daily basis can significantly affect its longevity. Operators play a vital role in the overall health of the equipment by following best practices that reduce unnecessary strain on the machine.

Proper Machine Setup and Alignment

Another one of the most critical things that will extend the life of your mattress tape edge machine is how well it is set up. Machines that aren’t aligned and calibrated properly will create a host of issues such as poor stitching quality, increased wear on the machine parts, and even breakdowns.

Key areas to check for proper setup:

Machine Head Alignment: The machine head must be aligned properly in relation to the mattress. Poor alignment also tends to lead to inefficient stitching and, over time, perhaps even damage.

Needle and Presser Foot Positioning: Set the needle and presser foot properly according to instructions from the manufacturer. This can also help prevent skipped stitches, thread breakage, or improper taping.

Tension Settings: Thread tension should be set accordingly to avoid extremely tight or loose stitches. If the tension is not good, there would be continued thread breakage or irregular stitching, which, over a period of time, would affect the machine’s overall performance.

A well-set machine can only become truly productive with good quality goods and less maintenance.

Proper Use of Machine Features

These tape edge machines are fitted with different capabilities, from full automation controls to variable stitching speeds, which make the work easier on the operators. All these capabilities, if used correctly, will reduce the wear and tear on the machine and extend its life.

Features to optimize:

Speed Control: There is a need for the application of proper speeds to handle particular materials. Accessing this machine at high speed constantly will result in excessive heat building up that over time will lead to wearing parts out faster.

Thread Type: Thread type should be of the proper type for each specific mattress type. Inexpensive or improper thread causes strains on the machine resulting in thread breakage and wear on the machine.

Material Handling: While guiding the mattress through the machine, operators must not pull or force the fabric so it does not cause misalignment or break the needle.

By understanding and properly using the features of the machine, operators are able to optimize the machine’s performance while minimizing unnecessary damage or stress.

Troubleshooting Common Issues

Even with routine maintenance and proper operation, mattress tape edge machines may develop certain problems. Most of the problems can be resolved through troubleshooting before graduating to major repairs. Here are some of the most common issues and their solutions.

Needle Breakage

The most frequent problem found with mattress tape edge machines is the breaking of the needles. This may happen for several reasons: incorrect machine setup, wrong type of needle, and high tension.

Solutions:

Check Needle Size: Use appropriate needle size according to the thickness and type of material being used. Too small or too big a needle can easily break.

Check Needle Alignment: When the needle is set wrong, it may strike the throat plate or some other part of the machine and snap.

Thread Tension Adjustment: If the tension of the thread is too high then it may exert undue stress on the needle and result in the breaking of the needle.

By addressing these potential causes, needle breakage can be minimized.

Skipped Stitches

Skipped stitches may result in poor-quality finished products and can be indicative of a problem with the setup or condition of the machine.

Solutions:

Recheck Machine Alignment: Generally, if the needle is not in line with the hook, there is much chance for skipped stitches. Recalibrate the machine as informed by the manufacturer.

Replace Worn Parts: A worn or damaged needle or hook can be a common cause of skipped stitches. Regularly check these parts and replace them at the right time.

Tension Setting: If the tension is set too loose, the thread may not be able to catch, causing skipped stitches.

Taking the time to regularly check for and address the causes of skipped stitches will improve product quality and machine reliability.

Inconsistent Stitching

Irregular stitching can be due to ill-set tension or to defective feeding mechanisms.

Solutions:

Recalibrate Tension: The tension should be preset according to the type of material and thread in use.

Inspect Feed Dogs: Worn feed dogs cannot support the material down but above the feed dogs for proper feeding. Replace or service the feed dogs, depending on the circumstance.

Check Presser Foot Pressure: If presser foot tension is too low or too high, depending on the material’s thickness and texture, it will shift or bunch the material during sewing and thus create irregular stitches.

Regularly monitoring these aspects of the machine will help maintain a consistent stitch quality.

Conclusion

The longevity of mattress tape edge machines is directly related to how well they are maintained and operated. Implementing a routine maintenance schedule, following operational best practices, and troubleshooting minor issues before they become major problems are all critical steps in keeping the machine running smoothly.

By dedicating time and resources to proper care, manufacturers can not only improve the efficiency of their production lines but also ensure the consistent quality of their mattresses. In the long run, a well-maintained mattress tape edge machine will minimize repair costs, reduce downtime, and maximize productivity, making it an invaluable investment for any mattress manufacturing operation.

Связанные с ними товары