- Home » Maintenance Tips for Keeping Your Mattress Flanging Machine in Top Condition

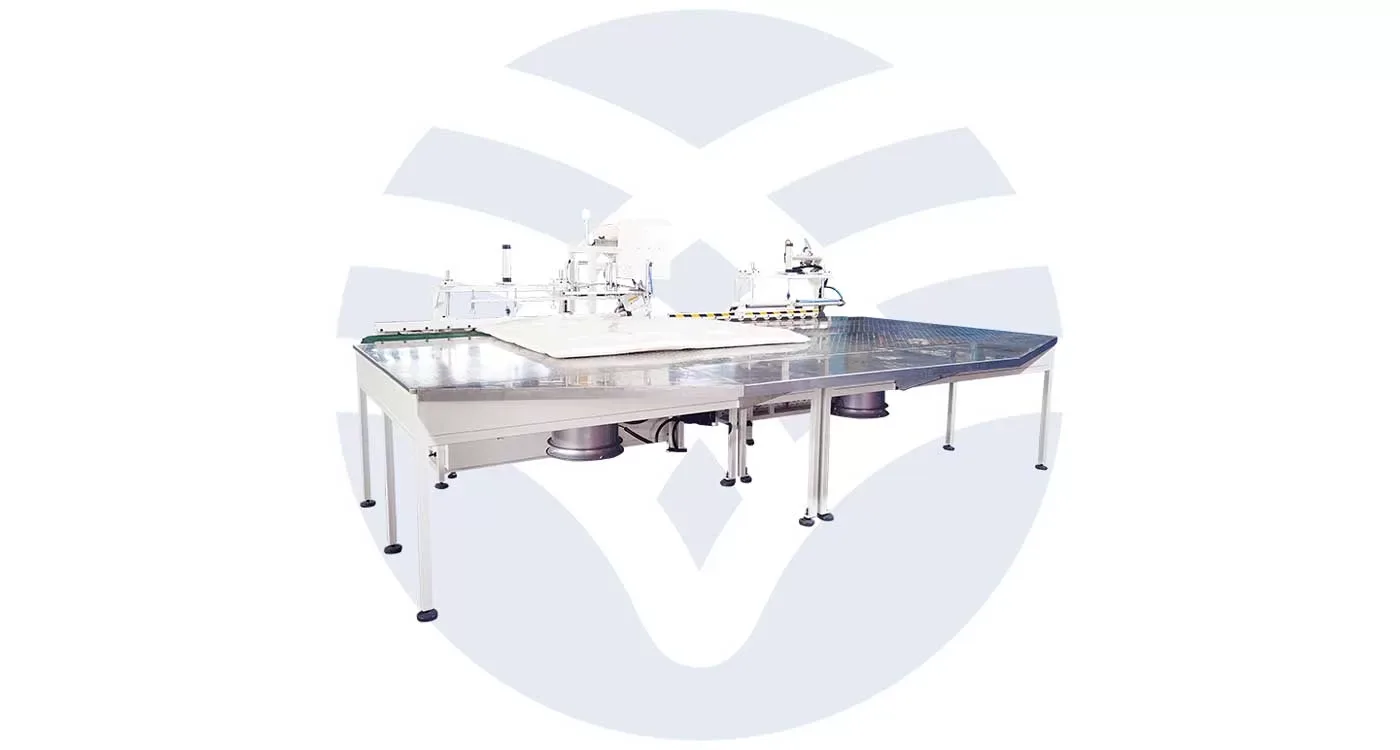

Mattress flanging machines are critical in mattress manufacturing companies, offering a continuous process for border attachment to mattress panels. Regular maintenance is required to ensure constant performance in production and to extend the life of your machinery.

In this article, we outline important maintenance tips you can follow to keep your mattress flanging machine running smooth and at peak performance, saving you from unwarranted line downtime and assuring quality in your products.

Understanding the Importance of Regular Maintenance

Why Maintenance Matters

Proper maintenance of your mattress flanging machine will ensure the efficiency and reliability of its function. Regular maintenance will keep unexpected downtime at bay, extend the life of the equipment, and maintain your product quality. The failure to plan maintenance may lead to major problems, including equipment breakdown, loss of production time, and inflated repair costs.

The Cost of Neglecting Maintenance

Small problems can be big if it is not maintained regularly. In case the needle is somewhat out of line, it will start missing stitches, and this ruins the quality of your finished product. This can wear down the interior of your machine in the long term and thereby raise the cost needed to repair it. Much more importantly, this may bring the production line to a grinding halt, thus delaying the completion of tasks at hand and disappointing customers.

Daily Maintenance Checks

Inspecting the Needle and Threading System

The needle and threading system are the two most important components of a mattress flanging machine. These elements should be checked daily for smooth working. Inspect the needle for any indication of wear or damage, such as burrs or bends. All these conditions can result in the skipping of stitches and the breaking of threads. The needle should be replaced immediately if any defect is found.

Cleaning the Machine

Dust, fluff, and other material particles that are a result of the machine’s usage will start to settle in your mattress flanging machine, thereby reducing its operational efficiency. Make it a point to clean the machine at the end of each day.

Use a soft brush or compressed air to sweep off any accumulation from the threading system, feed dogs, and the bobbin area. Keeping the machine clean prevents obstructions from befalling the machine’s parts in operation and also helps to hold on to the stitch quality.

Lubricating Moving Parts

Proper lubrication is essential for smooth machine operation, and your mattress flanging machine is no exception. Refer to the manufacturer’s guidelines on the points that need lubrication and the recommended type of lubricant. Lubricate these points either daily or as recommended in order to minimize friction, prevent wear, and ensure smooth movement of all components.

Weekly Maintenance Tasks

Checking Tension and Alignment

Tension and alignment are the two major influences on the quality of stitches. Set aside some time once a week to check the tension settings of your needle and bobbin threads, correcting them when necessary to ensure that the stitches are not too loose or too tight. Take a moment to set your needle and presser foot properly so that the fabric won’t slip from its hold, making your stitches irregular.

Inspecting the Drive Belt

The drive belt is responsible for transferring power from the motor to the machine’s moving parts. Over time, the belt may become loose or wear out, hence affecting how the machine performs. Check the drive belt for any signs of wearing, such as fraying or cracking. When it is loose, tighten it as instructed by the manufacturer or replace it when there are large wears on the belt.

Tightening Screws and Bolts

Constant vibration from frequent use may loosen the screws and bolts in a period. Visible screws and bolts should be checked weekly and those that have loosed should be tightened. These small details should be noted to prevent parts from shifting or coming apart which can cause malfunction of machines.

Monthly Maintenance Routines

Deep Cleaning the Machine

While daily cleaning might keep the machine in good shape, elaborate cleaning procedures should be carried out at least once every month. This would mean that the exterior panels of the machine should be dismantled to clean its interior components.

Using a vacuum or compressed air will drive out dust and dirt accumulations on the motor and gears, among other places that cleaning cannot easily reach. Deep cleaning ensures that all parts are free from contaminants that grossly impede performance.

Inspecting Electrical Components

Electrical components must also be evaluated monthly for damaged wiring and connectors. Check for wear, corrosion, and loose connections. Defective electrical components may cause malfunction or become a safety hazard. Consult a qualified technician for the necessary repairs if you find problems.

Evaluating the Feed Mechanism

The feed mechanism is responsible for moving the fabric through the machine. The feed dogs and other parts of this feed mechanism will eventually wear, thus reducing their grip on and smooth movement of the fabric. Inspect the feed mechanism monthly and replace worn parts to ensure trouble-free feeding of fabric and maintenance of stitching quality.

Quarterly Maintenance Procedures

Checking Motor Performance

The motor is the heart of your mattress flanging machine, thus, its performance should be checked quarterly. Watch out for any suspicious noise, grinding or squealing, which would indicate a problem with bearings or other internal parts of the motor. Monitor the temperature during operations to make sure it does not overheat. If problems are found, have it repaired by an expert to prevent further damage.

Assessing the Timing Mechanism

The timing mechanism controls the rise and fall between the needle and fabric and guides the correct sewing. Of course, it can go out of time due to constant use or wear. Check your timing mechanism quarterly to make sure everything is working properly. If the timing is wrong, set it according to the instructions provided by the manufacturer or seek help from a professional.

Testing Safety Features

Safety features, such as emergency stop buttons and guards, are designed to protect operators from injury. Test these features quarterly to ensure they are functioning correctly. If any safety components are not working properly, repair or replace them right away to maintain a safe working environment.

Annual Maintenance and Professional Servicing

Comprehensive Machine Inspection

It is recommended to perform at least an annual inspection by a qualified technician so your mattress flanging machine is always in top condition. The technician will check over the entire machinery, from the motor and timing mechanism to the feed system and electrical parts. They would detect any potential problems and carry out necessary repairs or adjustments that might be required to forestall problems.

Updating Software and Firmware

If your mattress flanging machine features computerized control, do not forget to update its software and firmware from time to time. Many manufacturers release updates aimed at enhancing performance, eliminating bugs, or simply implementing new features. Do this annually or as may be required to make sure that your machine can run with the latest enhancements.

Replacing Worn Components

Even with proper maintenance, some parts will be worn out with use and must be substituted. Replace worn parts during the yearly examination: the needle bar, presser foot, or motor brushes. This will ensure that fitting new high-quality parts keeps your machine running smoothly and reduces breakdowns.

Conclusion

Regular maintenance is required to ensure that your mattress flanging machine can provide long service in a very efficient way. This guide has given daily, weekly, monthly, and annual tips for implementation in order to ensure minimum breakdown chances while maintaining the quality of products and increasing the life span of machinery. Implementing a proactive maintenance program will not only protect your investment, but will also keep your production line running smoothly, ensuring your business remains competitive in the mattress manufacturing industry.

Связанные с ними товары