- Home » Key Considerations When Investing in a Mattress Flanging Machine

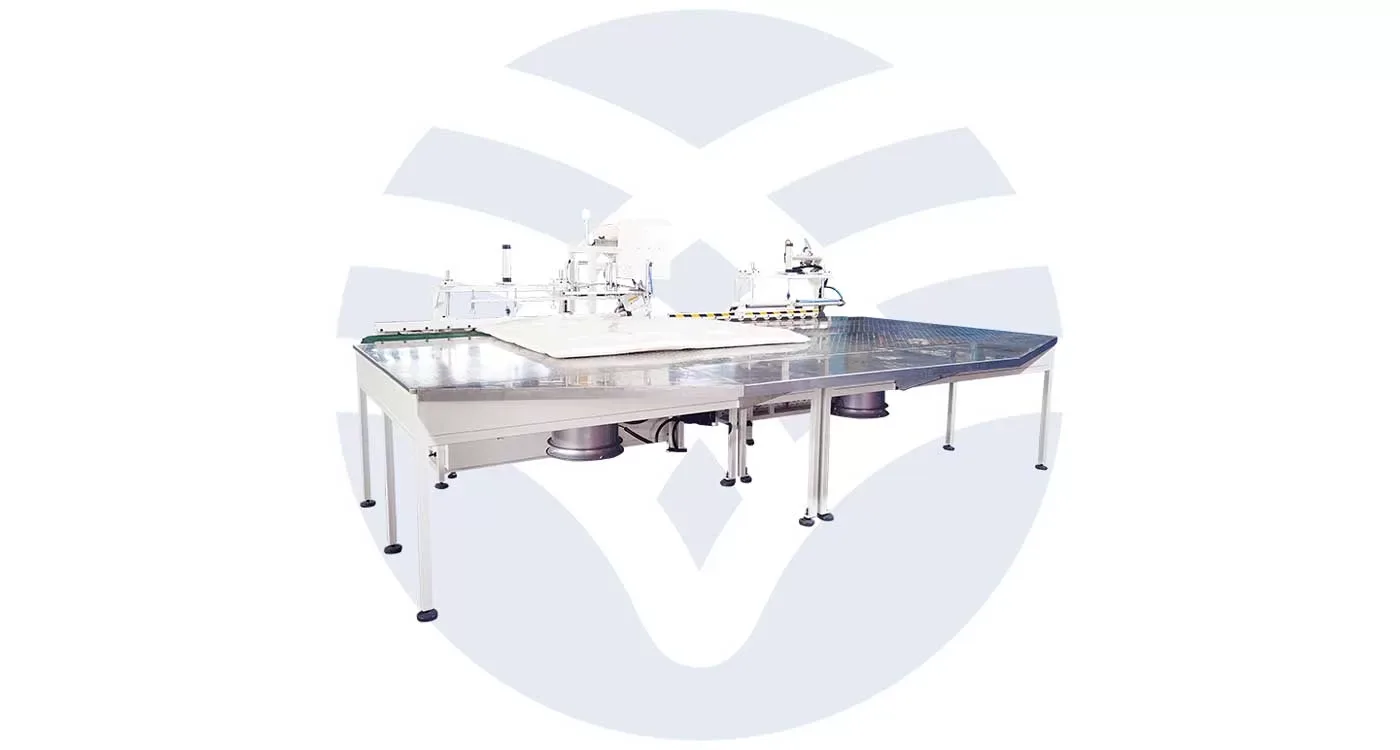

Investing in a mattress flanging machine is one of the most important decisions for any manufacturer in the bedding industry. This is special equipment that streamlines the mattress making process by stitching the mattress panels and borders together for durability, quality, and aesthetic appeal.

However, selecting the right machine requires a thorough understanding of your production needs, market demands, and operational goals. Here are some key considerations to guide your investment in a mattress flanging machine.

1. Understanding Your Production Requirements

Before entering the market, understand your needs related to production volume.

Production Volume: Determine the quantity of mattresses your factory produces daily or monthly. If you are a high-volume manufacturer, you require a flanging machine with high speeds since it will be in continuous operation without loss of quality. Conversely, small-scale operations may do well with smaller and more affordable machines to meet lower production levels.

Mattress Types and Sizes: Specify the type and size of mattresses that your company makes. Note that the machine is designed to handle different types of jobs, such as handling mattress thickness and materials as well as designs.

Material Compatibility: Ensure that the machine caters to the materials applied in your production line, such as foam, innerspring, or hybrid constructions. Some machines also specialize in stitching different fabric types, including knitted, quilted, or woven textiles.

2. Assessing Machine Features and Specifications

Modern flanging machines come equipped with various features designed to enhance productivity, precision, and ease of use. Some critical aspects to consider include:

Stitching Quality: High-quality stitching is essential to ensure a durable and professional finish. Look for machines known for consistent, clean, and secure seams, even during prolonged operation.

Speed and Efficiency: The machine’s speed affects production timelines. Some machinery allows for variable speeds that could potentially provide some leeway when you need to make adjustments on specific projects.

Automation Level: Planned automation of the machine will affect this decision. For example, a fully automated system can greatly reduce labor costs while simultaneously improving consistency, whereas a semi-automated machine would provide much more manual control of specialized tasks.

Durability and Build: A strong machine manufactured from high-quality materials will hold up to the demands put on it. Look for features such as corrosion-resistant materials and durable moving parts that will last far into the future.

Ease of Use: Easy-to-use interfaces, ergonomic design, and clear instruction manuals facilitate efficiency in operators and minimize the margin of error.

3. Evaluating Brand Reputation and Customer Support

The brand or manufacturer of the machine plays a vital role in your selection process.

Brand Credibility: It is always advisable to select reputed brands with an excellent reputation in the mattress manufacturing sector, such as Yuantian Machinery. Reviews, testimonials, and case studies give insight into their machines’ reliability and performance.

Warranty and Support: A strong warranty shows pride in the product. Additionally, determine if customer support is available after purchase along with maintenance services and available replacement parts.

Training and Installation: Some manufacturers provide training and installation, which ensures that your people know exactly how to operate the machine effectively.

4. Considering Total Cost of Ownership

The cost of a mattress flanging machine extends beyond its initial purchase price. Assess the total cost of ownership by factoring in:

Initial Investment: Compare prices across various brands and models, ensuring the features justify the cost.

Maintenance and Repairs: Routine maintenance and occasional repairs are inevitable. Opt for machines with easily accessible parts and straightforward repair processes to minimize downtime.

Energy Efficiency: Energy-efficient machines can reduce operating costs over time, particularly for high-volume operations.

Operator Costs: Automated machines may have a higher upfront cost but can result in savings due to reduced skilled labor requirements.

5. Adapting to Market Trends and Future Needs

The bedding industry is in constant evolution with the changing needs and preferences of consumers and new technological developments. Future-proof your investment by:

Ensuring Scalability: A machine you invest in should have the potential to scale up production as your business expands.

Adapting to New Designs: Machines with varied settings and multi-functional capabilities can also process a broader range of designs and materials, enabling you to meet an increasingly competitive market.

Technology Integration: Modern machines can have digital controls, IoT connectivity, or AI-powered functions that will enable better monitoring, diagnostics, and insights into production for informed decision-making.

6. Conducting a Cost-Benefit Analysis

A proper cost-to-benefit analysis helps or justifies the investment in such a machine.

Return on Investment (ROI): Calculate how the machine will improve productivity, reduce labor costs, and enhance product quality over time.

Break-Even Point: Determine how long it will take to recover the initial investment through operational savings or increased revenue.

Competitive Advantage: Check whether the feature in this machine will give an added advantage in quality, efficiency, or product differentiation from competitors.

Conclusion

Investing in a mattress flanging machine is a significant decision that can transform your production processes and enhance the quality of your products. By carefully evaluating factors like production needs, machine features, brand reputation, and long-term costs, you can choose a machine that aligns with your business goals. With the right machine, your mattress manufacturing operation will be well-positioned for growth and success.

Связанные с ними товары