- Home » Introduction to Bonnell Spring Machines: The Backbone of Traditional Mattresses

Bonnell spring machines are an inseparable part of a mattress manufacturing plant in the creation of traditional innerspring mattresses. The Bonnell springs have become very popular due to their strength, durability, and low cost, thus making them a favorite among many consumers and manufacturers.

This passage provides a comprehensive overview of Bonnell spring machines, detailing their history, working principles, advantages, and role in modern mattress manufacturing.

History of Bonnell Spring Machines

The Bonnell spring system goes back to the 19th century, when it was introduced as a reliable and robust solution in the support of mattresses. It was named after its inventor, and within a short time, Bonnell springs became very popular because of its resilient nature and ability to provide firm support.

The technology of Bonnell spring machines has undergone several changes over the years. The early models used to be highly labor-intensive and comparatively slow. The more recent models, though, are much more automatic and perform production quickly with constant quality, which makes it an integral part of modern mattress manufacturing.

Working Principles of Bonnell Spring Machines

Spring Formation

Bonnell spring machines start with a high-tenancy steel wire coiled into what has often been the familiar shape of an hourglass. The relevance of such a shape lies in the fact that it makes the spring compress and expand efficiently, thus yielding support and comfort.

Tempering Process

The springs are tempered to give them strength and durability after forming. Heating the springs to a specified temperature, then cooling them quickly, is how this process happens. This step is important in making sure that the springs retain their shape and stay resilient over time.

Assembly into Units

These tempered individual springs are then assembled into a spring unit. The process of assembly involves helical wires interlinking the springs into a homogeneous, integrated network. The resultant spring unit forms the core support structure of the mattress.

Advantages of Bonnell Spring Systems

Durability and Longevity

One of the main advantages associated with Bonnell spring systems is their durability. The tempered steel springs can take a lot of wear and tear, thus one can always be guaranteed that the mattress will have its resiliency and functionality over the years.

Cost-Effectiveness

The Bonnell spring systems are relatively cheap to produce; this is compared to some other types of spring systems for example the pocket springs. This cost-effectiveness makes it popular for budget mattresses without necessarily compromising on quality.

Firm Support

Bonnell springs offer firm and consistent support, thus making them perfect for those who love a little bit firmer feel of their mattresses. The design with interconnected springs keeps any weight evenly distributed across it, thereby reducing pressure points and promoting comfort.

Role of Bonnell Spring Machines in Modern Mattress Manufacturing

Automation and Efficiency

Advanced automation in modern Bonnell spring machines greatly improves production efficiency. In operation, they are able to handle huge volumes of spring units with minimal human involvement, hence cutting down on labor costs and improving output.

Consistency and Quality Control

Automated Bonnell spring machines ensure a high level of consistency in spring production. This consistency is crucial for maintaining uniform quality across all mattresses produced.

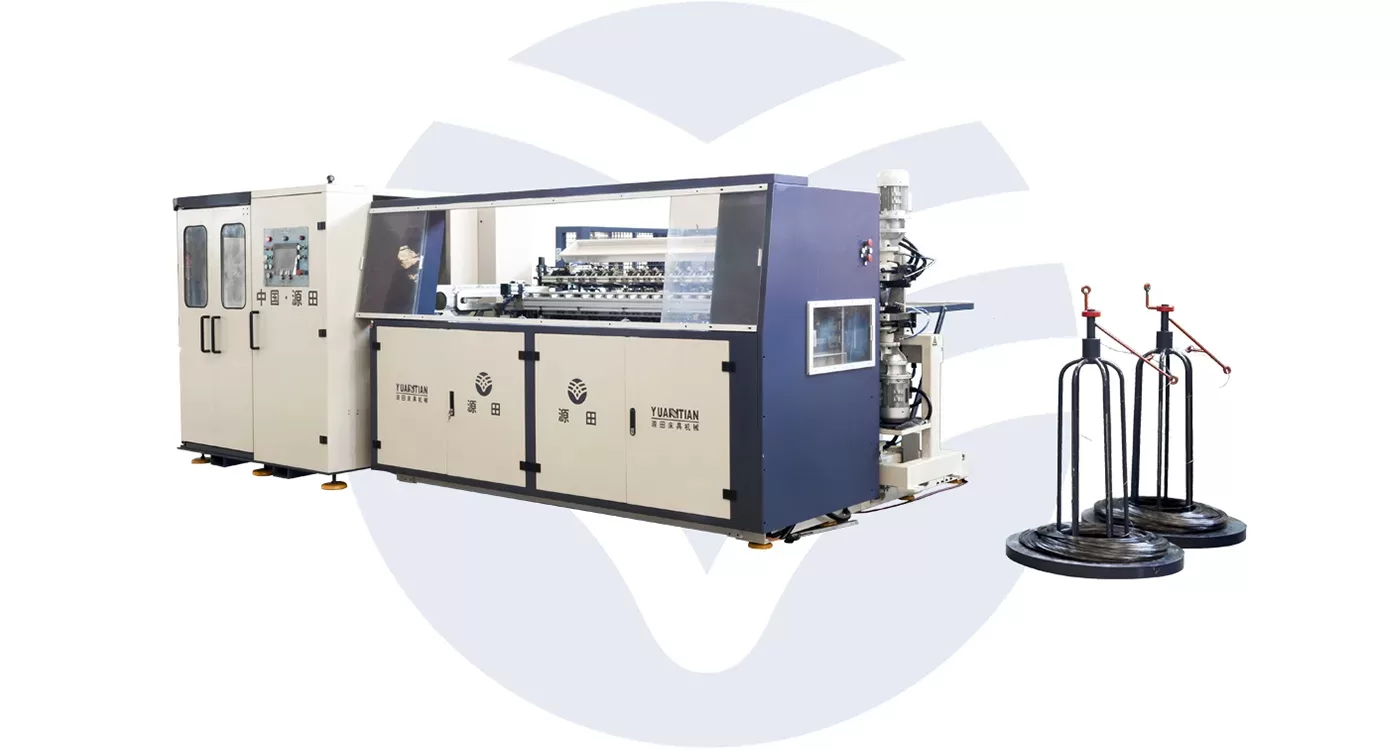

Additionally, modern Bonnell spring machines, such as Yuantian YT-JCH-3, are often equipped with quality control systems that detect and eliminate defective springs, further enhancing the overall quality of the final product.

Versatility in Mattress Design

Bonnell spring units can be easily fitted into traditional innerspring mattress designs or even hybrid models that combine springs with foam or other materials. This versatility accommodates a great diversity of consumers’ tastes and needs.

Key Features of Modern Bonnell Spring Machines

High-Speed Production

High-speed production for modern Bonnell spring machines significantly reduces time in the making of spring units. This increased speed therefore boosts productivity, allowing large-scale production capability.

Precision Engineering

The precision engineering attests that each spring formed and tempered to specifications conveys modern Bonnell spring machines. This is essential for retaining the structural integrity and performance of spring units.

User-Friendly Interface

Most of the Bonnell spring machines in the market today are fitted with interfaces that allow the operators to easily monitor and control the process of production. The interfaces come with touch screens and automated settings that allow easy operation and servicing of the machine.

Innovations in Bonnell Spring Technology

Advanced Materials

Recent developments in Bonnell spring technology include advanced material usage in order to enhance their performance and durability. This includes high-carbon steel and other alloys that provide enhanced strength and resilience.

Eco-Friendly Production

With growing concerns regarding sustainability, manufacturers are finding eco-friendly ways of producing Bonnell springs. This incorporates recyclable materials and energy-efficient ways of manufacturing that reduce the impact on the environment.

Integration with Smart Technologies

Another crucial aspect is the integration of smart technologies into Bonnell spring machines to monitor and adjust conditions in real-time, achieving optimum production with less maintenance downtime or correction of errors.

Challenges and Considerations

Maintaining Machinery

Though holding tremendous benefits, Bonnell spring machines require regular servicing to ensure they work at optimal standards. This includes scheduled inspections, cleaning, and changes of worn parts. Without regular maintenance, production may be delayed due to poor quality.

Balancing Cost and Quality

Even though Bonnell spring systems are somewhat inexpensive, it does not necessarily mean that manufacturers should totally sacrifice material and production quality for cost savings. The benefit lies in investing in high-quality steel and advanced machinery to create spring units more durable and efficient.

Meeting Consumer Preferences

Manufacturers need to adjust products accordingly as consumer tastes and preferences continue to shift. Bonnell spring systems offer firm support, but some consumers may prefer the feel of pocket springs or memory foam. A wide range within the product line makes it easier for companies to meet the demands of more customers.

Conclusion

Bonnell spring machines are the backbones of traditional mattress manufacturing, they provide a reliable and economical solution for turning out top-quality innerspring mattresses. From their historical roots to modern innovations, these machines were always under development to meet the demands of the industry.

Durability, efficiency, and versatility give Bonnell spring machines a lasting reason to remain a must for mattress manufacturers. They will continue to play their important role in continuing to provide comfortable and supportive mattresses to consumers all over the world with changing technology and consumer preference.

Связанные с ними товары