- Home » Innovative Mattress Packaging Solutions for Efficient Manufacturing

The mattress industry has seen significant advancements in recent years, especially in how mattresses are packaged and delivered to consumers. Efficient packaging is crucial for reducing logistics costs, minimizing storage space, and ensuring products reach customers in pristine condition.

For manufacturers, choosing the right packaging solution can also streamline operations and improve sustainability. This guide will explore innovative mattress packaging solutions, including different types, their benefits, and considerations for manufacturers looking to improve their packaging processes.

The Importance of Efficient Mattress Packaging

This makes packaging a core concern in both manufacturing and the supply chain, from issues related to warehouse space to customer satisfaction. Efficient packaging also greatly reduces environmental impact, given that most manufacturers now want to minimize waste and carbon emissions caused during the transportation of products.

Key Benefits of Efficient Mattress Packaging

- Reduced Shipping Costs: Compact packaging fits more units on one truck or container, lowering per-unit shipping costs.

- Space-Saving Storage: Smaller and well-packed mattresses require less storage space, thereby saving warehouse costs on behalf of the manufacturer.

- Improved Product Protection: Well-packaged mattresses avoid the possibility of damage while in transit. This improves the overall satisfaction the customer will experience with the product.

- Sustainability Goals: Eco-friendly material usage along with a reduction of packaging footprint adheres to modern sustainability goals and vocalizes environmental concern for the modern consumer.

Types of Mattress Packaging Solutions

These vary from efficient to well-protected options, all made possible by advances in materials and machinery.

Roll-Pack Machines

One of the popular machines used to compress and roll mattresses into compact, cylindrical shapes is the roll-pack machine. This consists of vacuum-sealing the mattress, compressing it, and then rolling it into a tight bundle.

- Advantages: The roll-packed mattresses are smaller and thus easier to transport, saving both the extra cost of shipping and storage. These are also easier for the customer to handle.

- Applications: Suitable for foam and hybrid mattresses and some pocket spring mattresses. Ideal for a manufacturer with high-volume distribution channels

- Considerations: In addition, not all mattresses support such packing, and machinery represents a serious investment initially.

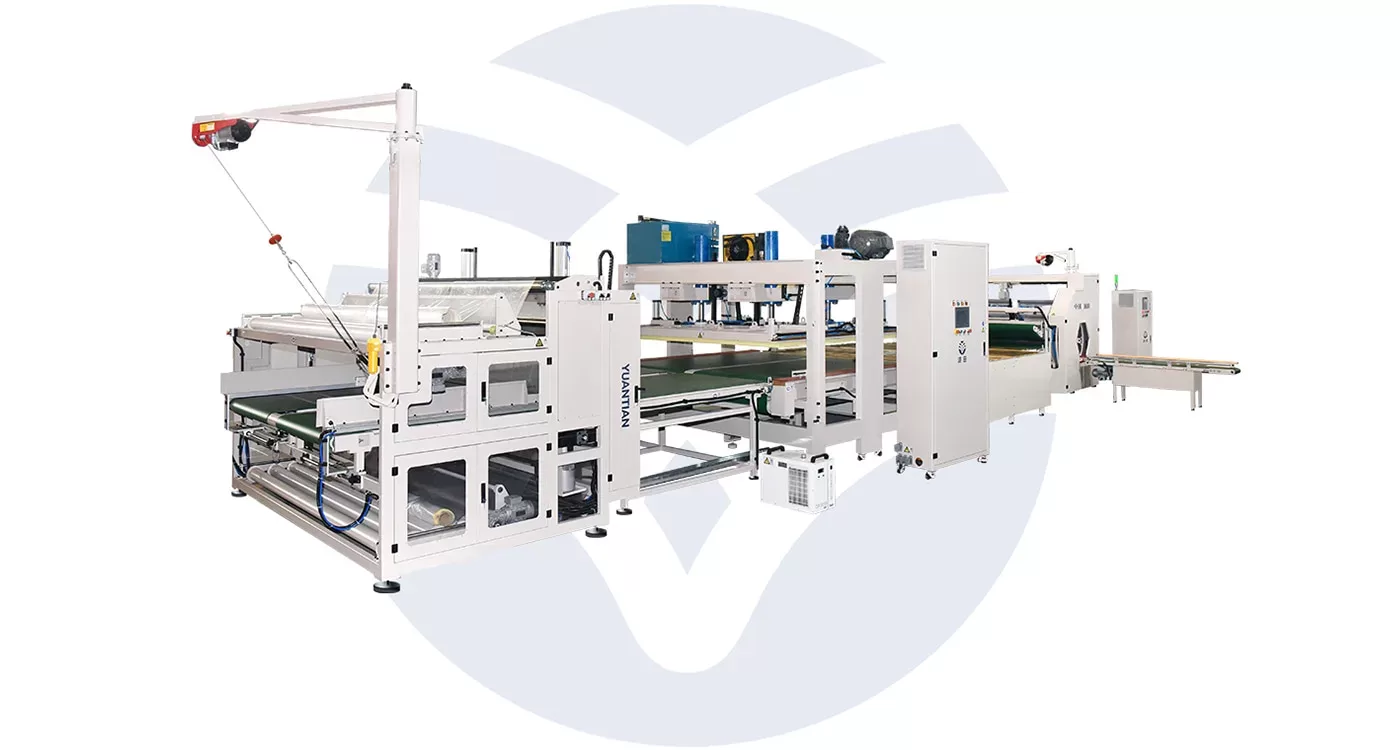

Vacuum Packed Flat Compression Machine

Flat compression machines are vacuum-padded, compressing the mattress into a thinner profile but maintaining it flat. This is done by vacuum-sealing and pressing the mattress down into a compact, flat package.

- Advantages: It doesn’t change the original shape of the mattress-flattened instead of rolled. Suitable for high-volume shipping and e-commerce distribution.

- Applications: Used mostly on high-density foam mattresses and a few spring mattresses.

- Considerations: Although the machinery is thought to be inexpensive on flat-packed mattresses, the compressed shape might still occupy a lot of space compared to roll-packing options.

Box-Packing Systems

Box-packing systems pack mattresses inside a box after they have been compressed and, in some cases, rolled. The mattress is placed inside a protective carton, which provides additional protection during shipping.

- Advantages: Boxed mattresses are easy for consumers to handle and provide an easy unboxing experience. Additionally, boxes also offer a higher branding option with logos and information.

- Applications: Online mattress brands and direct-to-consumer sales can use it. It accommodates roll-packed or flat-compressed mattresses.

- Considerations: Optimization of the box dimensions and materials, which would offer protection with branding and also be economical.

Key Features to Look for in Mattress Packaging Machinery

Therefore, the right packaging machinery should be selected in view to maximize efficiency, quality, and cost-effectiveness in mattress manufacturing. Presented below are the features to be considered when comparing various types of mattress packaging machines:

Compression Force and Compatibility

The machine should have enough compression force to meet the packaging format intended. For example, foam mattresses will have lesser compression compared to innerspring or hybrid mattresses. Therefore, the manufacturers must determine the compatibility of the machine with different types of mattress materials to achieve the desired output.

Automation Capabilities

It increases the rate of packaging and saves labor costs. Most of the compression, sealing, and packing into a box of automated machines have programmable settings that can make the different batches as consistent as possible. Its best application is in the high-output daily operations of big manufacturing plants.

Speed and Throughput

Packaging speed is one of the critical factors for effective production lines. Some high-end packaging machines can process up to 180 mattresses per hour, which significantly increases productivity for high-demand manufacturers. Manufacturers must assess their expected production volume and choose machinery that meets their throughput goals.

Eco-Friendly Features

Some of the packaging machines currently designed are made to support recyclable or biodegradable materials due to the increasing demand for sustainability. Also, energy-efficient motors and settings on the machine help reduce overall energy usage in line with eco-friendly manufacturing goals.

Innovations in Sustainable Mattress Packaging

Mattress manufacturers are finding new ways to make mattress packaging eco-friendly due to the increasing concerns over environmental impact. Here are a few new concepts that incorporate sustainable mattress packaging:

Biodegradable and Recyclable Packaging Materials

However, replacing traditional plastic in packaging with biodegradable or recyclable materials can definitely reduce waste. Cardboard boxes made out of recycled materials are an option that some manufacturers use, or they use biodegradable wraps in place of plastic films. Such sustainable materials may help attract eco-conscious customers and also help reduce landfill waste.

Reusable Packaging for High-End Mattresses

Reusable packaging for luxury mattresses is starting to get some traction. These packages are designed to be returned and reused, with many being made from solid materials such as cloth or even hard/strong cardboard. In this way, reusable packaging complements the premium nature of the product and reinforces the concept of a circular economy.

Reduced Packaging Volume Through Efficient Design

Packaging machinery that compresses mattresses into smaller, optimized volumes reduces the overall amount of material to be used. Some more innovative machines are designed to store mattresses in space-saving volumes by compressing them into unconventionally shaped spaces where maximum space efficiency can be achieved without compromising product integrity.

Selecting the Right Packaging Solution for Your Manufacturing Needs

The packaging solution chosen depends on things like the type of product, the volume of the production, and the type of distribution model. Based on their specific needs, the manufacturers should see the packaging solution providers for an optimal match for the operation.

- Product Type: Various types of mattresses, like foam, hybrid, or spring, might require different kinds of packaging solutions. While roll-packing suits foam mattresses, traditional spring mattresses may require flat compression.

- Production Volume: High output volume manufacturers benefit from the automation and high speed of packaging. The low-output companies find that manual and semi-automatic machines are cheaper to be bought.

- Distribution Model: If the company depends much on the e-commerce and direct-to-consumer models, roll-pack and box-pack will be convenient in this respect since shipping is made less expensive and deliveries will not be a complex affair.

Conclusion

Innovative mattress packaging solutions can offer significant benefits to manufacturers, from reducing logistics costs to enhancing sustainability. By selecting the right packaging machinery and adopting eco-friendly materials, manufacturers can optimize their operations, align with modern sustainability goals, and improve the overall customer experience. Investing in efficient and innovative packaging solutions is not only a strategic choice for today’s competitive market but also an opportunity to support a more sustainable and customer-centric approach to mattress manufacturing.

Связанные с ними товары