- Home » Innovations in Mattress Packaging Technology

In recent years, the mattress industry has seen significant advancements, not just in the materials and construction of mattresses but also in the technology used for packaging them. Innovations in mattress packaging technology have transformed the way mattresses are stored, transported, and sold, benefiting manufacturers, retailers, and consumers alike.

These advancements have improved efficiency, reduced costs, and enhanced customer satisfaction. This passage explores the various innovations in mattress packaging technology and their impact on the industry.

The Evolution of Mattress Packaging

In the past, mattresses were obtained in bulk form and, as a result, caused a lot of hassle in terms of storage and transportation. Normally, mattresses are transported in a flat form, so any transportation arranged for the flat is invariably costly. Sufficient transportation of such goods mandated extra logistic issues as well.

In addition, the old-fashioned approach entailed bringing immense inconvenience to the consumer while transporting the mattress from the store to his home. The invention of the roll-pack technology was quite a landmark in mattress packaging.

In general, it involves compressing and rolling mattresses into smaller bundles that can easily be handled and transported. Besides, roll-packing technology completely transformed the logistic side but also gave way to the ever-booming online mattress market with direct selling to consumers and convenient home delivery.

Key Innovations in Mattress Packaging Technology

Vacuum Sealing and Compression

Vacuum sealing and compression make up the foundation of new mattress packaging technology. The process involves deflating the mattress to a size considerably smaller than its original size. After deflation, the mattress is then vacuum sealed in plastic to retain the compressed state that it will be in until it reaches the consumer. The main advantages are:

Space Efficiency: Since the mattress is compressed, one can fit a larger number in a single container compared to the other types. As a result of this, the freight is much cheaper and also less harmful to the environment.

Ease of Handling: The smaller and partial weight packages are easy to handle and are mainly not likely to cause damage during shipment. This also enables the consumers to take the mattress very easily to their homes.

Roll-Packing

Roll-packing technology goes a step further and rolls the vacuum-sealed mattress into a cylindrical format. This further brings in more benefits:

Enhanced Portability: Rolled mattresses, especially massage rolled mattresses, can easily be moved upstairs, downstairs, and through really narrow corridors, which in turn eases delivery.

Retail Display: Compact rolled mattresses are easier to stockpile and display at retail stores. This enables the retailer to carry more products within a limited space.

Advanced Materials and Construction

The innovations in mattress materials and construction have also played a pivotal role in the augmentation of packaging technology. From the point of view of compressibility and roll-packing, mattresses of today are designed for flexibility and resiliency. The major developments that took place are:

High-Resilience Foams: Advanced foam formulations, including memory foam and latex, resist compression and snap back to form almost instantaneously to assure the comfort and support features that the mattress should offer.

Hybrid Designs: Hybrid mattresses are developed to incorporate innerspring coils with foam layers to be more compressible yet maintain durability and performance.

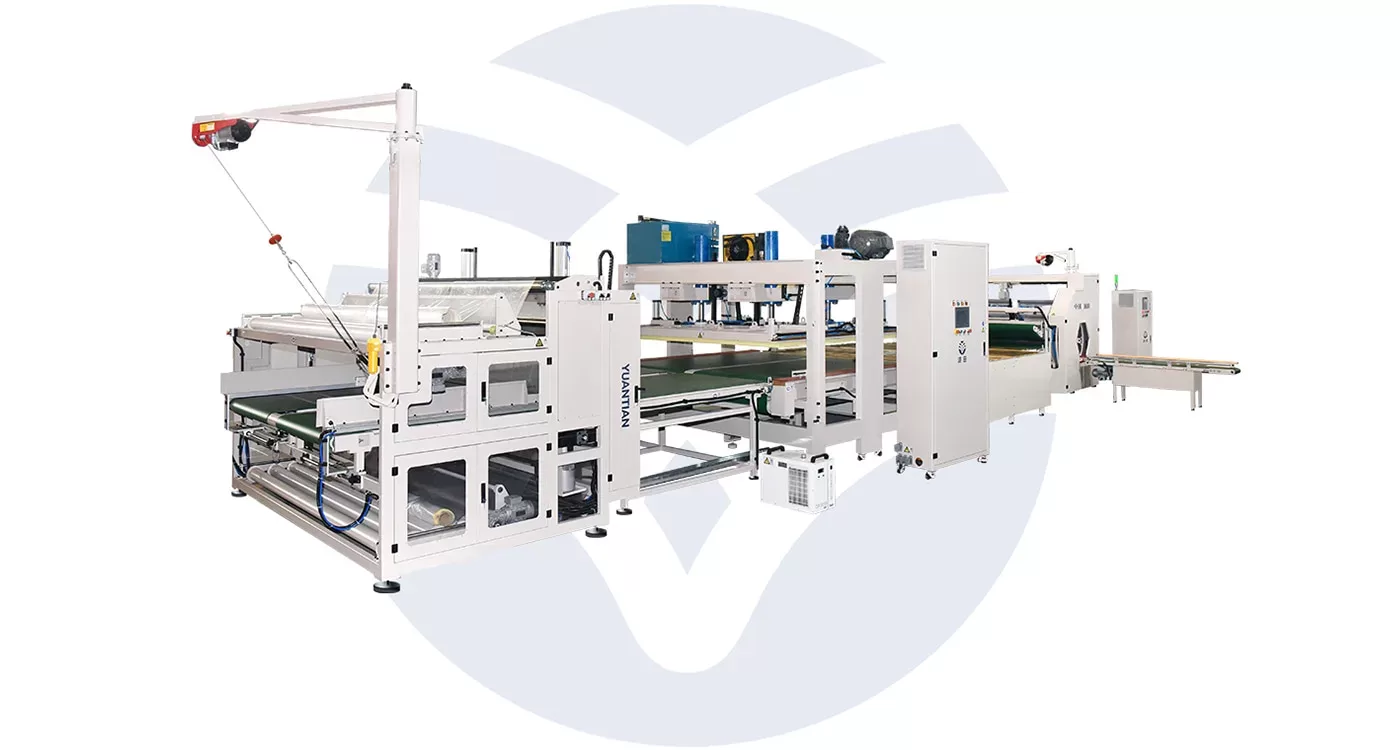

Automated Packaging Systems

Efficiency, accuracy, and consistency are changed in mattress packaging by the evolution of automation. Automated mattress packaging systems can perform the entire process, starting from compressing and rolling to sealing and labeling. The main benefits realized from automation are as follows:

Increased Throughput: Processing a substantial number of mattresses to meet the highest quality standards quickly technically boosts integrated production capacities and lowers lead times.

Consistency and Quality Control: In this way, the packing of mattresses is automated to ensure the quality control of mattresses in their package, thus reducing defects and offering a uniform consumer experience.

Sustainable Packaging Solutions

With increasing concern regarding the environment, the mattress industry is fast moving towards green and sustainable packaging solutions. These innovations strive to reduce waste, lower the impact on the environment, and appeal to the green sensibilities of consumers. Vital advances are:

Biodegradable Plastics: In vacuum sealing and wrapping, most firms are now using biodegradable plastic materials, which create minimal environmental impact.

Reduced Packaging Material: Such innovation in the design and development of materials leads to newly created thin and robust packaging that reduces the total use of plastic without any compromise on protection.

Reusable Packaging: Some companies are exploring reusable packaging solutions that can be returned, cleaned, and used again, further minimizing waste.

Smart Packaging and Tracking

The integration of smart technology into mattress packaging is an emerging trend that offers numerous benefits for logistics and customer experience. Smart packaging solutions include:

RFID and QR Codes: Embedding RFID tags or QR codes in packaging allows for real-time tracking and inventory management. Retailers and consumers can easily track the location and status of their mattresses throughout the supply chain.

Interactive Packaging: By scanning themselves scannable codes, intelligent packaging can reveal more information to consumers, such as unboxing instructions, product details, and ways of taking care of the product, by referring him/her to online content.

Impact on the Industry

The achievements in mattress packing technology have shifted the goalposts significantly for this particular mattress industry in several sectors related to business: logistics, retailing, and consumer behavior.

Logistics and Distribution

Enhanced packaging technology allowed for working out harder logistics and distribution processes while saving related costs drastically. The option of compression and rolling mattresses reduced shipment volume and further increased the number of units that could be shipped in a single shipment. Again, this translates to less transportation costs and fewer carbon emissions, all while adhering to sustainability goals.

Retail and E-Commerce

This has been propelled forward by the rise of roll-pack and vacuum-sealed mattresses, which have made it much easier to sell online. It is easy to have a variety of products on e-commerce platforms with the ease of direct-to-door delivery.

Storage and display space can be maximally utilized by the retailer, and more products can be displayed on the showroom floor area without huge showrooms. These have given opportunities for newer brands to easily enter the market and connect with consumers directly.

Consumer Experience

Modern packaging technology benefits customers in several ways, such as the following:

Convenience: Packages are more compact and lightweight; hence, easier to handle and ship. They bring less of a headache when being unpacked and need services for professional delivery less often.

Affordability: Lower shipment costs are generally passed through in the form of lower prices to the final customers in the case of high-quality mattresses.

Sustainability: Eco-friendly packaging solutions resonate with environmentally conscious consumers, enhancing brand loyalty and satisfaction.

Future Trends

Mattress packaging has a lot to look forward to with an advancement in technology that is ever on the increase. Some future trends may include:

Advanced Compression Techniques: New methods of compressing and rolling mattresses more efficiently, preserving quality as it further reduces size.

Smart Packaging Integration: Popularization of smart packaging solutions that will enhance tracking, customer interaction, and inventory management.

Sustainable Practices: Continuous focus on sustainability by developing new materials and new processes, which will minimize environmental impact.

Conclusion

Innovations in mattress packaging technology have revolutionized the mattress industry, offering significant benefits in terms of logistics, retail, and consumer experience. From vacuum sealing and roll-packing to automated systems and sustainable materials, these advancements have improved efficiency, reduced costs, and enhanced product quality.

As the industry continues to evolve, further innovations will likely drive even greater improvements, ensuring that both manufacturers and consumers reap the rewards of these technological advancements.

Связанные с ними товары