- Home » Innovations in Mattress Flanging Machines: Automation and Efficiency

In the ever-evolving world of mattress manufacturing, the demand for increased production speed, precision, and cost-efficiency has led to a range of technological innovations.

Among the most critical advancements are those found in mattress flanging machines—vital pieces of equipment responsible for joining the fabric and other materials of the mattress cover at the edges. These machines are integral in creating a seamless, durable finish, and recent innovations in automation and efficiency are revolutionizing the industry.

The Traditional Mattress Flanging Process

Historically, mattress flanging was a somewhat labor-intensive process wherein workers manually attached the outer cover to the edges of the mattress by sewing using sewing machines.

Generally speaking, this does tend to be skilled labor, but it’s usually aesthetically pleasing and robust. The whole process was not easy to consistency, speed, and quality control. Through the years, manufacturers have tried to find ways to improve this operation to reduce human error and lower labor costs.

Rise of Automation in Mattress Flanging

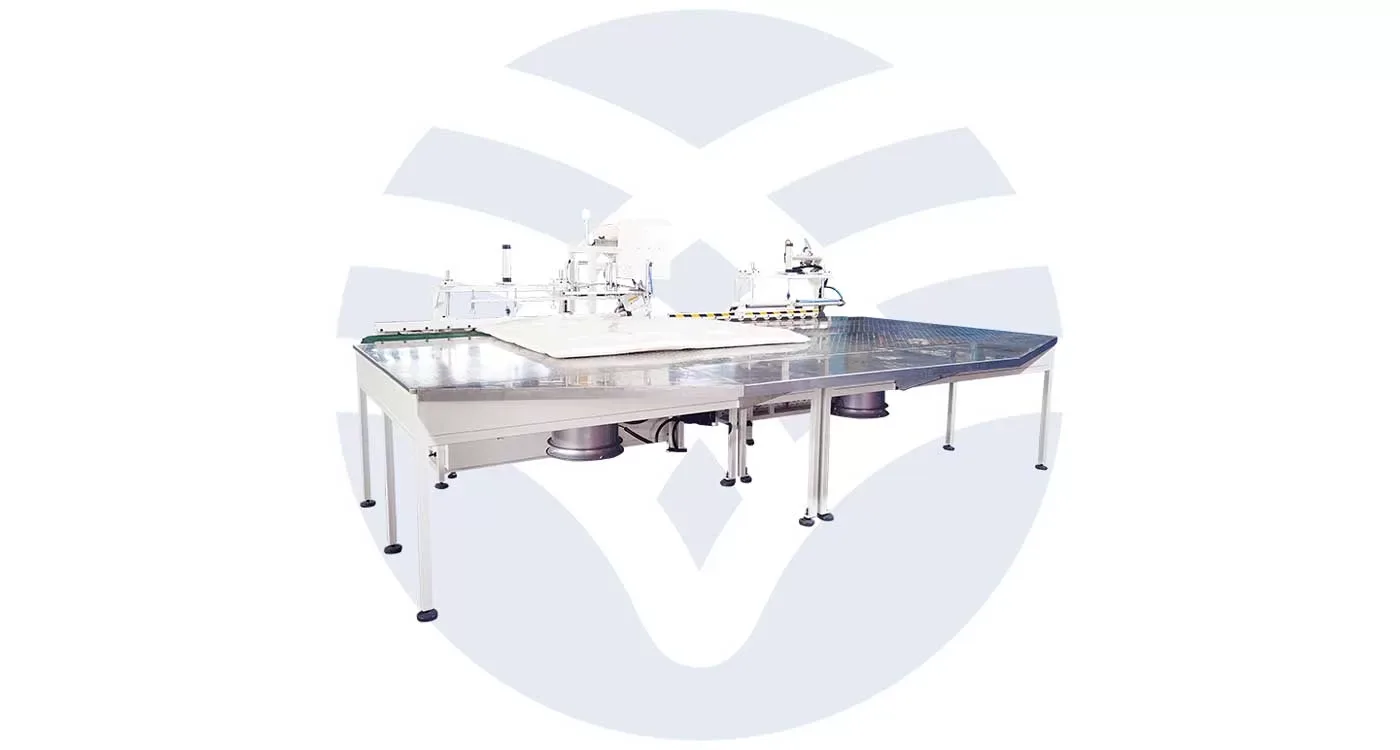

Automation has slowly been introduced to the flanging process in the mattress industry due to advances in technology. Using robotic arms, conveyor systems, and advanced software, automated machines now perform sewing, stitching, and even applying specific finishing touches. The machines have given a chance for the manufacturer to drastically reduce labor costs and increase production speed, while at the same time allowing high levels of precision and quality.

Probably the most important advantage of automated flanging machines is that they can process large volumes of mattresses with minimal human labor. Often, such machines can run almost continuously, day and night, stopping only for infrequent maintenance, a factor that affects productivity and profitability directly. Standardization is also meted out to the quality of the finished product since automation can eliminate human errors.

Key Innovations in Flanging Technology

Robotic Integration and Precision Sewing

The incorporation of robotic systems that can stitch and manipulate fabrics with high precision constitutes one of the most remarkable innovations in mattress flanging machines.

These robots are fitted with highly precise sensors that ensure perfect alignment of the fabric before sewing, hence reducing errors and enhancing the overall quality of the flange. The automation of the sewing process also speeds up production, allowing manufacturers to produce more mattresses in less time.

Programmable Logic Controllers (PLCs)

Programmable logic controllers or PLCs are one of the indispensable parts of any of the modern flanging machines. Operators can pre-program certain flanging patterns, stitch types, and sewing speeds into the machine through these controllers.

This customization allows for manifold variations in mattress sizes, different fabrics, and stitch patterns that could be handled on the same machine without manual setup for every run. This reduces the setup time and enhances machine adaptability, hence greatly improving overall operational efficiency.

In-Line Inspection Systems

One of the most valuable innovations in recent flanging machines is the integration of in-line inspection systems. The incorporation of these systems into stitch detection allows continued monitoring with cameras and sensors that continuously monitor the stitching quality, fabric tension, and alignment during the flanging process.

If a defect is detected-such as misalignment or a skipped stitch-it will alert the operator or automatically halt production until the issue has been resolved. Automated quality control minimizes the use of manual inspection, which is generally time-consuming and inconsistent, hence making sure only quality products leave the production line.

Laser Cutting and Welding

Some of the latest flanging machines incorporate laser cutting and welding technologies. These systems serve to cut the fabric accurately to prevent fraying and give clean edges prior to the beginning of the sewing process. The addition of laser welding allows for the fabric to be fused at the edges, which may eliminate the need for conventional sewing.

This technology accelerates the manufacturing process and decreases the wear and tear on sewing components, thereby prolonging the machines’ lifespan.

Energy-Efficient Motors

Other developments in mattress flanging machines are the application of energy-efficient motors and drives. By using top-of-the-range motor technology, energy use during production will be minimal. This reduces operational costs and contributes to sustainability within the sector. Reduced energy consumption creates less noise in the operation of machines to provide a better working environment for operators.

Smart Connectivity and Data Integration

Like most industries, mattress manufacturing has embraced IoT technologies in the form of smart machines for better monitoring and maintenance. Smart connectivity enables a flanging machine to transmit data in real-time about its condition regarding cycle time, production speed, or even maintenance. This is often integrated into a central management system that lets manufacturers keep track of several machines all at once.

It allows performance tracking and provides chances to identify upfront issues that may lead to downtime. Predictive maintenance tools can look back through historical data to predict when parts will need replacement and then help avoid unexpected machine failures and reduce costly maintenance.

Efficiency Gains and Cost Reduction

Various key gains in efficiency have been realized with the automation of the mattress flanging process. Perhaps the most obvious of these is the dramatic reduction in production times. Compared to manual labor, automated systems work at a much faster pace, meaning a manufacturer can make more mattresses in a shorter period, thereby increasing the general output or throughput.

The increased precision of automated machines reduces fabric waste during production. The flanging in a mattress cover is a critical operation, and it becomes a reason for flawed fitting due to an error during stitching. Automation removes this risk, leading to less waste, fewer rejections of products, and easier work processes.

Automation and the integration of smart technologies also cut labor costs. The initial investment in an automated system is high, but overall savings are considerable. Companies have less dependence on skilled labor for the flanging process. The greater speed of production can now allow manufacturers to offer more competitive pricing, which may prove to be the decisive factor in such a competitive mattress market.

Future Directions

The progress of technology is not going to stop in the future, mattress flanging machines are very likely to embrace even more advanced innovations. AI and machine learning will further enhance the flanging process, enabling the machines to adapt immediately to different fabric types, stitching patterns, or environmental conditions. AI could also have larger predictive maintenance roles, making the machines even more reliable and reducing human intervention to a minimum.

Moreover, the development of green materials and production methods might affect the shape of flanging machines. For example, machinery that could process organic or recycled fabrics with the same consistency in quality would be a point of high interest for manufacturers looking to adhere to the increasing demand for green products.

Conclusion

The innovations in mattress flanging machines, particularly in automation and efficiency, have transformed the mattress manufacturing process. These advancements not only lead to faster production times and reduced labor costs but also ensure a higher quality product with less waste.

As the industry continues to evolve, further technological advancements will likely continue to shape the way mattresses are made, offering both economic and environmental benefits. By embracing automation and intelligent manufacturing techniques, mattress producers can stay competitive and meet the ever-growing demands of the modern consumer.

Связанные с ними товары