- Home » How to Select the Right Mattress Flanging Machine for Your Factory

Choosing the right mattress flanging machine is an important decision, especially for any mattress manufacturer. This attaches the border or the flange to the mattress and is responsible for the final quality and durability of the product. Since there are many options available, all of which offer a range of features and capabilities, this becomes a very complex process of selecting the right machine. The article will take you through the most vital factors to consider so that you can select the right mattress flanging machine for the particular needs of your factory.

Understanding Mattress Flanging Machines

Before diving into the selection process, it is important first to understand what a mattress flanging machine is and its role in the mattress manufacturing process.

What is a Mattress Flanging Machine?

A mattress flanging machine is a special machine that attaches a flange, which is a border that is added to the two sides of a mattress, namely the top and bottom panels. It is an important step in tying the mattress layers in place and giving it a professional finished look. Flanging also fortifies the mattress for durability.

Types of Mattress Flanging Machines

These machines come in several types: manual, semi-automatic, and fully automatic. Each has its relative advantages and is suited to different levels of production volume and complexity. It becomes quite instructive to understand these types in making informed decisions.

Manual Flanging Machines: A hand-operated machine, it befits operations that are quite smaller, or even the making of mattresses as customized items.

Semi-Automatic Flanging Machines: These are the ones that fall in between the fully manual and automatic flanging machines. These flanging mattress machines can be adopted in mid-size factory setups.

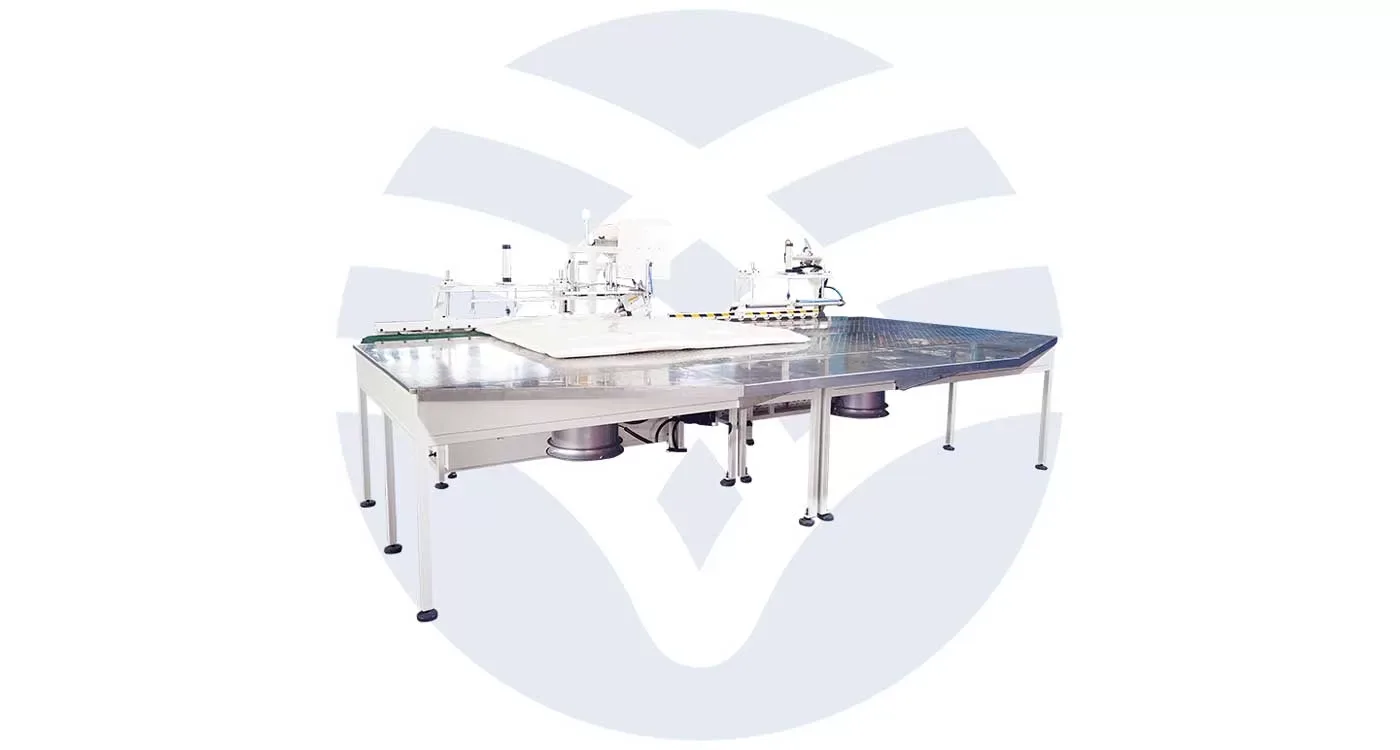

Fully Automatic Flanging Machines: These machines are fully automated to ensure high efficiency and consistent working procedures. These machines can be used in large factories, where massive mattress production is required.

Key Factors to Consider When Selecting a Flanging Machine

When selecting a mattress flanging machine, several factors should be taken into account to ensure that it meets the specific needs of your production line.

1. Production Volume

One of the very first considerations is the volume of production your factory has. This will, to a great extent, dictate or influence the type of flanging machine you will need.

Where the volume of mattresses being produced in your factory is small, then perhaps all you need is a manual or semi-automatic flanging machine. These are generally cheaper and provide the flexibility required in smaller batches or even for customer orders.

To sustain a high volume of production, a factory will require a fully automatic flanging machine. Fully automatic flanging machines are the best to handle large volumes with unparalleled quality and less downtime.

2. Machine Speed and Efficiency

The speed and efficiency of a flanging machine show your production capacity. You will need to assess the speed of the machine in terms of the volume of production that you intend or hope to achieve.

If you want to meet high and tight production schedules, then you would want a machine that is designed to allow good stitching speed. However, it will have to be high enough without compromising on stitching quality. Automation features such as the auto feeding and cutting of materials greatly contribute to increasing efficiency because of less time and labor use for each mattress.

3. Operational Flexibility and Customization

Besides, flexibility and personalization of operations bear significance for factories that produce a variety of mattress types and sizes.

The flanging machine shall be designed with variable settings to suit different mattress thicknesses, fabrics, and edge styles. For example, the capacity for adjusting to different mattress thicknesses allows it to comfortably produce other product lines without much need for reconfiguration.

Versatility within a flanging machine will enable more creativity and accomplish the diversified demands of customers. Machines offering more stitch patterns will allow greater flexibility in designing their respective products. This is quite important for those factories that offer customized or premium mattresses. Moreover, even if the machine has advanced features, the machine should not be too complicated to operate.

4. Durability and Build Quality

Long-term performance and reliability largely depend on the durability and build quality of the flanging machine.

The machine should be fabricated from high-quality materials that can withstand continuous use in an industrial setting. The needle plate, feed dog, and presser foot are some of the components that need to be of hard-wearing metals. Consider machines from reputed manufacturers known for reliable and durable machinery.

5. Maintenance and Support

Maintenance and after-sales support will, however, be the factors that determine whether your flanging machine is cost-effective even in the long run. It follows that you select a machine that is easy to service with parts easily accessible and whose maintenance instructions are clearly explained.

Good manufacturer support may make quite a big difference in your overall experience with the machine. Check the warranty offered by the manufacturer. Generally speaking, the longer the warranty period reflects confidence in the toughness or durability of the machine. Reliable technical support cannot be compromised, especially for automated machines whose troubleshooting and repair may require specialized knowledge.

6. Cost Considerations

While price cannot be the only determining factor, it indeed holds a crucial position when the total cost of ownership regarding initial purchase price, maintenance, and operating costs are in discussion.

The initial price of the flanging machine would depend on the kind of machine and its functionalities. Generally speaking, manual machines cost less but over time, with labor invested, they can have more options. Automated ones will have a higher initial capital cost, but will have lower costs in labor and will create more production efficiency.

Look at the machine’s long-term value, considering durability, efficiency, or the possible increase in the capacity of production in your factory. Then, calculate the expected return on investment by drawing comparisons between machinery prices and the projected rise in efficiency in production and reduction in labor costs.

Conclusion

Selecting the right mattress flanging machine for your factory is a decision that requires careful consideration of various factors, including production volume, machine speed, durability, flexibility, maintenance requirements, and cost. By thoroughly evaluating these aspects, you can choose a machine that not only meets your current production needs but also supports the future growth and success of your business.

A well-chosen flanging machine can significantly enhance your factory’s efficiency, product quality, and overall competitiveness in the market. Whether you opt for a manual, semi-automatic, or fully automated machine, ensuring that it aligns with your specific manufacturing requirements is key to maximizing its value and ensuring long-term operational success.

Связанные с ними товары