- Home » How to Operate a Mattress Tape Edge Machine: A Step-by-Step Guide

The operation of the mattress tape edge machine is quite a critical job to undertake in mattress manufacture. It sews the edges of the mattress together, usually with strong and durable tape, creating the finished seam that gives the mattress its professional, clean appeal. Although operating a mattress tape edge machine may seem daunting to a newcomer, once the proper knowledge and understanding of the machine’s components, its various processes, and their safety features are learned, then the operation of such a machine becomes quite easy and seamless. This process will explain how to operate a mattress tape edge machine with the help of necessary safety tips and best practice recommendations.

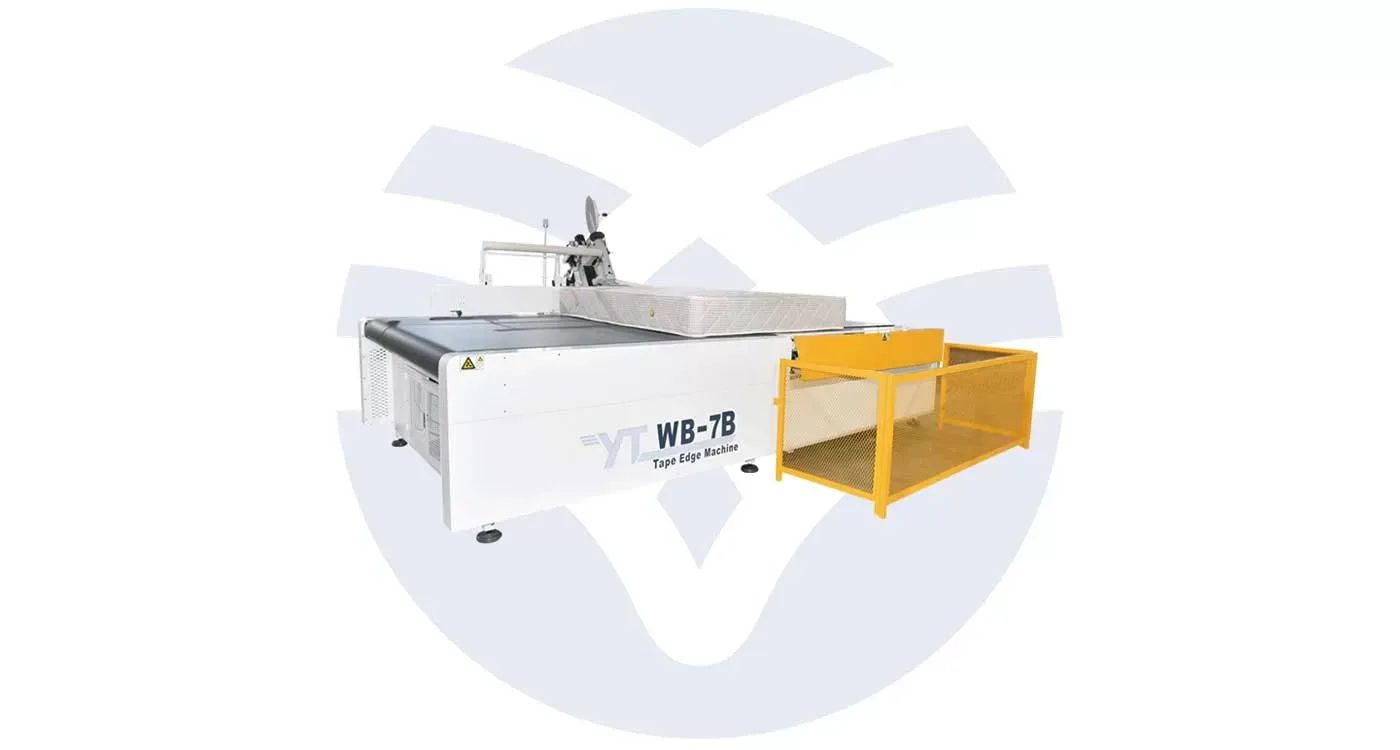

Understanding the Mattress Tape Edge Machine

Before making use of the mattress tape edge machine, it is significant to understand what its main function is, what components build it, and what type of mattress it can deal with.

What is a Mattress Tape Edge Machine?

A mattress tape edge machine is used for binding the edges of the mattress together with fabric tape so that the layers are kept in place for a finished look of the mattress. The machine stitches along the mattress perimeter to create a robust seam that secures the layers intact during the operation of the mattress. It’s not just the structural integrity of the mattress that is provided by the tape edge but also the aesthetic beauty.

Key Components of a Tape Edge Machine

The basic elements of the mattress tape edge machine will facilitate its operation to be smooth and efficient:

- Sewing Head: This is the major stitching mechanism that moves the needle to attach the tape onto the mattress.

- Tape Guide: This holds the tape in place and ensures it is fed through the sewing head evenly.

- Walking Foot or Conveyor: Conveys the mattress through the machine when the stitching is applied.

- Adjustable Work Table: The mattress can be turned or moved in various directions during stitching.

- Operator Controls: Handles that allow the operator to control the speed, tension, and movement of the machine.

Different models of tape edge machines may have additional features such as variable height adjustments for mattresses that are considerably thicker or computerized controls that automatically set the required values.

Preparing to Operate the Tape Edge Machine

Before the machine is switched on and production embarked on, there are a few preparatory steps to be taken so that everything is set and the machine is ready to work.

Safety Precautions

Safety is always paramount as far as industrial machinery is concerned. It is important, before attempting to operate the tape edge machine, to:

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and closed-toe shoes.

- Clean up: Clear the area around the machine of everything that is not necessary, to avoid tripping or accidentally touching the machine in mid-operating.

- Machine guard check: Check that protective guards are in place, especially over the needle and at moving parts.

- Be acquainted with the stop button: Know where the stop button is to immediately stop the machine when an accident is about to happen.

Inspecting the Machine

Before commencing work on the machine, keenly check that the machine is in good working condition. Amongst other things, check the following:

- Threading: Thread the machine correctly with the required type of thread and color.

- Tape supply: Load the tape into the tape guide and position it ready for stitching.

- Needles and Tension Settings: Verify the needle does not exhibit wear or damage and that tension settings are at the correct setting for the fabric and tape utilized in the operation.

- Motor and Belts: Verify the motor and belts operate properly and do not indicate any clear wear or deterioration. Mattress Setup

Setting Up the Mattress

Preparation of the mattress before stitching is everything to the final outcome. Place the mattress on the work table and ensure a proper hold thereof. Raise or lower the work table, as the different machine types may require, depending on the thickness of the mattress. In that same connection, ensure proper alignment of the mattress to avoid uneven seams when stitching.

Operating the Mattress Tape Edge Machine: Step-by-Step

Once you have taken a good look at the machine and prepared your mattress, you are now all ready to commence the taping process.

Starting the Machine

- Switch the power on: This can be accomplished by pressing the power button or by means of pulling a lever.

- Position the Mattress: Take the mattress edge to the start position under the needle, positioning the tape in a way that it is in line with the edge.

- Align the tape: The tape should be correctly positioned in the tape guide and at the raw edge of the mattress, leaving space for stitching.

Sewing the Mattress Edges

- Engage slowly: With assistance from operator controls, the machine is engaged slowly to start stitching. The speed of operation can be slow at the beginning in order to secure the tape in its correct position and alignment.

- Mattress guiding: Guide the machine while operating. Guide the mattress through the sewing head, keeping it level and on target. Control the speed of mattress movement through the foot pedal or handle on the machine. Keep your hands away from the needle and moving parts.

- Stitch around corners: When coming to the corners, slow down and gently feed the mattress to make smooth, even stitches. Some machines have a pivot function, which will also help at corners.

Completing the Seam

- Overlapping: Once you reach the beginning of the seam, start again a few inches in to ensure the stitching is secure and long-lasting.

- Secure the thread: Once the seam is complete, use the thread-cutting feature available on the machine if it has one, or cut the thread and tie it off so that it doesn’t unravel.

Troubleshooting Common Issues

During the operation, you are likely to find a couple of common issues that occur. Knowing how to quickly address them will minimize any potential downtime and prevent damage to the mattress.

Uneven Stitching

Poor tension or misalignment might also cause the tape to stitch unevenly. To rectify this,

- Check thread tension: The tension setting should be changed in such a way that it feeds properly and evenly through the needle.

- Reposition the tape: The tape will be perfectly aligned in the tape guide, ensuring that it fully covers the mattress edge.

Skipped Stitches

Skipped stitches are often caused by a worn-out needle or incorrect machine timing. To resolve this:

- Replace the needle: If the needle is damaged or worn, replace it with a new one.

- Check machine timing: Ensure the needle and bobbin are synchronized for proper stitch formation. Consult the machine manual for guidance on adjusting timing if needed.

Thread Breakage

Thread breakage generally happens due to incorrect threading, tension problems, or using the wrong kind of thread. If the thread breaks, follow these steps:

- Re-threading the machine: Correctly re-thread the machine to ensure that the thread passes through all the tension points.

- Adjust the tension settings: Reduce the tension a bit and test it on a scrap piece of cloth before you resume working on the mattress.

- Use appropriate thread: Use proper thread type and size regarding the type of fabric and the type of tape to be sewn.

Shutting Down and Maintenance

Proper shutdown and periodic maintenance are important for long life and continuous function with the reliability of the machine.

Shut Down of the Machine

After completing the stitching properly, the machine should be shut down with safety as follows.

- Turn off the machine: The machine should be switched off and disconnected from the power supply system.

- Clean the machine: This would entail removing any lint, dust, and other fabric debris, which could build up on the machine during operation.

- Inspect and maintain: Check for wear such as worn needles or loose belts and replace them when appropriate.

Routine Maintenance

Regular maintenance will keep the tape edge machine running at its best. This would include the following

- Oil Application: Apply oil on the moving parts of the machine, such as the head and the conveyor, to reduce friction and wear.

- Check for wear on the belts and pulleys. Replace when necessary.

- Cleaning the sewing head: If necessary, clean fabric lint and/or dust from the sewing head.

Conclusion

A mattress tape edge requires practice and attention to detail in order to become perfect for the person using it. Knowledge of the parts, proper machine setup, and considerations regarding safety concerns will enable you to effectively build top-of-the-line mattresses with professional finishes in an efficient manner. Routine maintenance and troubleshooting will keep your machine performing well and ensure that the performance lasts for a long time.

Связанные с ними товары