- Home » How to Operate a Mattress Flanging Machine

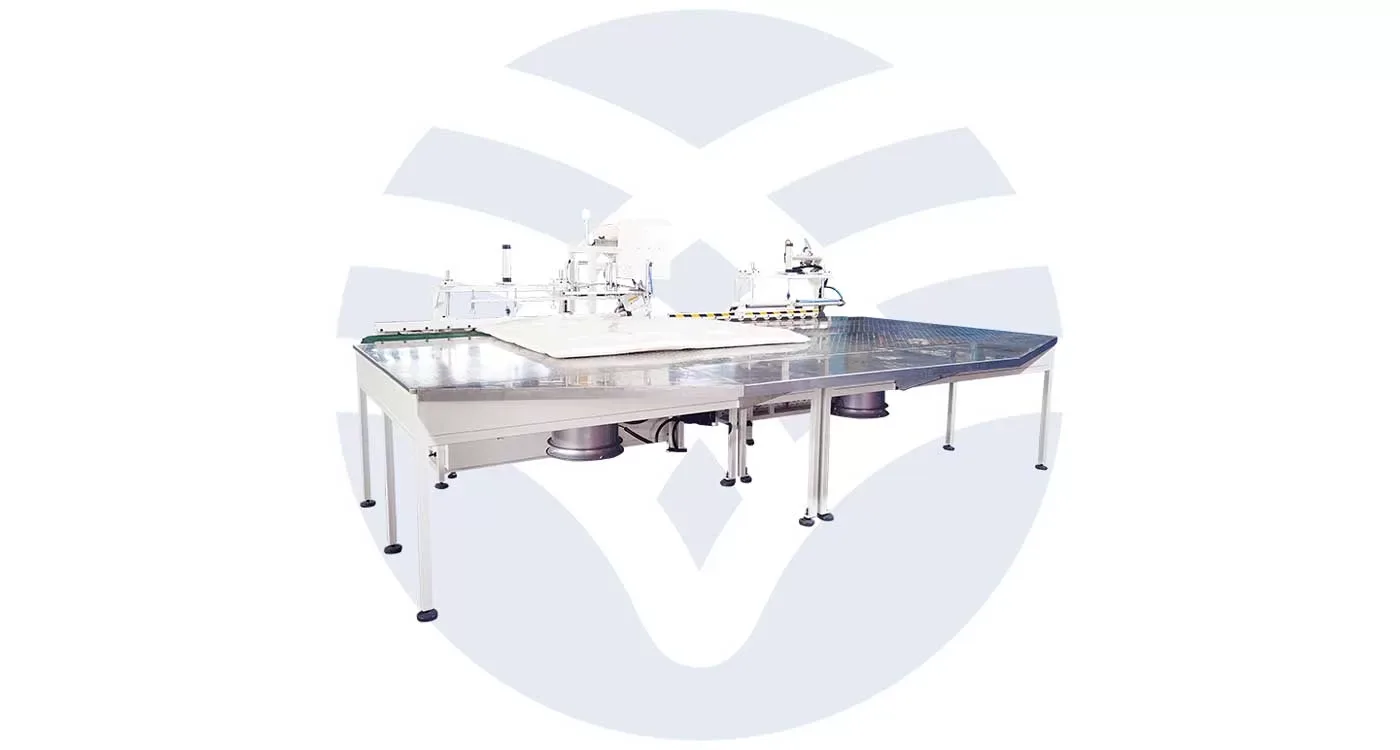

Operating a mattress flanging machine is a crucial skill in the mattress manufacturing process. This machine is used to sew the border material to the top and bottom panels of a mattress, creating a smooth and reinforced edge. Proper operation ensures the durability and aesthetic quality of the mattress.

This passage shows a step-by-step guide on how to set up, operate, and maintain a mattress flanging machine. Also, common problems and relevant solutions are talked about.

Understanding the Mattress Flanging Machine

Before the machine is operated, you need to learn about the basic components and their functions:

Sewing Head: It is basically the heart of the machine, comprising a needle and thread-formation mechanism.

Needle Assembly: It comprises a needle, presser foot, and feed dogs that function in coordination to provide stitches.

Thread Tension Mechanism: Regulates thread tension, so the formation of the stitch is the same.

Fabric Feeding System: Transports the mattress panels through the machine.

Control Panel: This enables the operator to regulate the various parameters of the operation, such as stitch length and speed.

Frame and Table: These parts of the sewing machine support it and provide a flat surface for the material as the stitch is applied to it.

Setting Up the Machine

Threading the Machine

– Proper threading of the sewing machine according to a given machine manufacturer’s instruction is the first stage of settings. The process generally involves the thread passing via several guides, a number of tension discs, and finally reaching the needle.

– Ensure the bobbin is correctly wound and inserted. The thread should be free of knots and tangles.

Needle and Thread Selection

– Needles should match the type of materials and at the right size for sewing. A recommendation of the appropriate size may be found in the manual given in the sewing machine.

– Always go for a quality type of thread that matches the fabrics you will use to avoid breakage of threads and at the same time to produce sound seams.

Adjusting Tension

– The tension control knob can be used to adjust the thread tension. Tension needs to be sufficient to prevent loose stitches but loose enough not to break the thread.

– Test the tension on a remnant piece of fabric before sewing.

Setting Stitch Length and Speed

– The stitch length should be set in proportion to the type of material used and the seam strength required. For thicker material, longer stitches are generally used.

– Adjust the machine to move at a speed that you are comfortable with and depending on how hard it is to sew.

Operating the Machine

1. Preparing the Fabric

– Smooth the mattress panels over the table, making them wrinkle-free.

– Line the edges of materials that are supposed to be stitched up, and put fabric clips or straight pins in, if necessary.

2. Feeding the Fabric

– Position the fabric under the presser foot. The feed dogs will grip the fabric and move it through the machine.

– Lower the presser foot to hold the fabric in place.

3. Starting the Machine

– Switch the machine on and start sewing at a medium pace. Gradually guide the fabric without any rushing to feed it in.

– Keep your hands a safe distance from the needle to avoid injury.

4. Monitoring the Stitching

– Continuously monitor the stitching to ensure even and secure seams. Make adjustments to the tension or stitch length as needed.

– If you notice any issues such as skipped stitches or fabric bunching, stop the machine and troubleshoot the problem.

5. Completing the Seam

– As you approach the end of the seam, slow down the machine to maintain control.

– Backstitch a few stitches to secure the end of the seam, then lift the presser foot and remove the fabric.

6. Inspecting the Work

– Check for loose threads, or maybe spots where the stitching didn’t catch in a few spots. Cut the extra thread off.

– Make any necessary adjustments to the machine settings before continuing.

Maintenance and Troubleshooting

Keep your mattress flanging machine always up to mark using the following maintenance tips and common troubleshooting steps:

Cleaning the Machine

After every operation, ensure to wipe the machine dry to remove dust, lint, and fabric chaff from work so far. Take note of the sewing head and feed dogs. Clean tight spaces using a soft brush or compressed air.

Lubrication

As recommended by the manufacturer, lubricate machines. Due to sound lubrication, friction and wear between the moving parts are minimized. Apply a little recommended oil, excess oil attracts dust.

Checking for Wear and Tear

Check for wear on the needle, thread tension discs, and feed dogs. Replace any worn part to complement flawless stitching performance. Observe the belts and gears of the machine to ensure that they are not damaged and replace if necessary.

Common Issues and Solutions

Thread Breakage: Apply proper tension in the thread and good quality of thread. Check if there are any obstructions at any point around the path of the thread.

Skipped Stitches: Quite often, there is a discarded use of the wrong size or type of needle. Check the timing between the needle with the hook and readjust, if necessary.

Fabric Jamming: Readjust the presser foot pressure and clean and place the feed dogs correctly.

Inconsistent Stitch Length: Probably at the worn stage, the feed dogs, or the tension of the thread is not equal. Ensure free feeding material.

Advanced Tips for Efficient Operation

Use Quality Materials

Of course, quality needles, threads, and fabrics are very instrumental for reducing hassle of sewing and making a good quality mattress in most general terms.

Operator Training

Proper training of operators. All operators must know all the functions, settings, and maintenance operations of a machine.

Documentation

Keep detailed records of maintenance activities, repairs, and part replacements. This documentation helps track the machine’s condition and anticipate future needs.

Regular Inspections

There should be regular checks to identify problems before they cause downtime. This is a form of proactive measure and will help save money and time while ensuring the quality of production is maintained at all times.

Software Updates

If the machine uses computerizing controls, then one has to update the software. Most manufacturers may update such software due to the introduction of new features to fix noted defects in their software.

Conclusion

Conclusion

Operating a mattress flanging machine involves understanding its components, setting it up correctly, and following best practices for sewing and maintenance. By selecting the right materials, adjusting settings appropriately, and performing regular maintenance, you can ensure efficient operation and high-quality output.

Proper training and adherence to troubleshooting guidelines will help you address common issues swiftly, minimizing downtime and enhancing productivity. With these skills, you can maintain the longevity and performance of your mattress flanging machine, contributing to the overall success of your mattress manufacturing process.

Связанные с ними товары