- Home » How to Ensure Precision with Your Mattress Flanging Machine

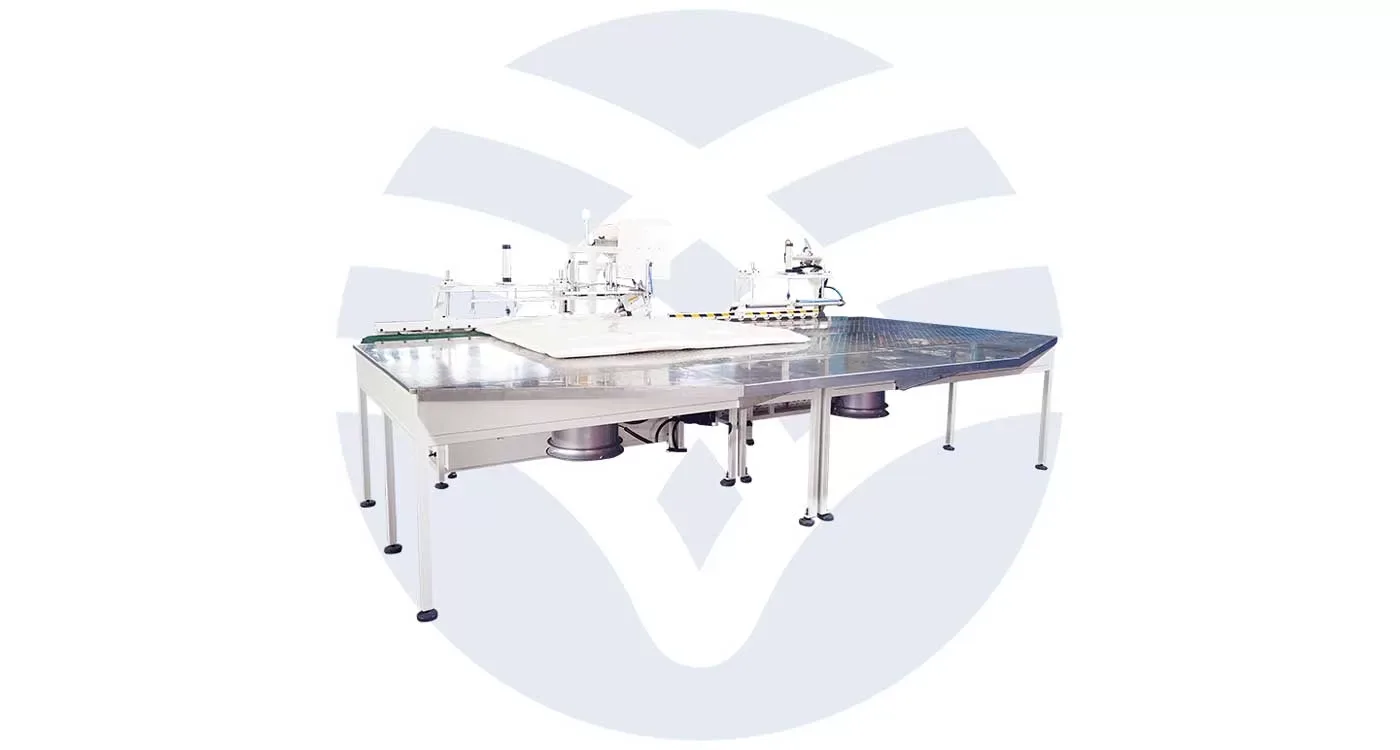

Mattress automatic flanging machines are an essential resource in the mattress manufacturing procedure for stitching to come up with good edges for each mattress. Precision in the flanging process affects both the durability and aesthetic of the mattress, making it critical for manufacturers to optimize their machines to produce clean, uniform seams.

This guide explores best practices for achieving precision with an automatic mattress flanging machine, including calibration, routine maintenance, operator training, and leveraging advanced technology.

Importance of Precision in Automatic Flanging Machines

Precision in automatic mattress flanging machines will relate to the quality, appearance, and endurance of each mattress. The advantages accruing from such automated machines are invaluable, especially for those productions that take high volumes, since they increase productivity while reducing the chances of errors from humans.

Ensuring that the machine is well calibrated, maintained, and used means that the producer of the mattress can present an excellent product that can satisfy customer expectations on both durability and appearance.

Benefits of Precision Flanging

Precision stitching means that every mattress manufactured has consistent seams to make the mattress more visually appealing and also to provide more stability. The accurate seams will diminish waste, reduce reworks, and not make things so frenzied, thus, it will improve the whole process of manufacturing. Further, strong, even stitching will reinforce the edges of mattresses to withstand regular use without fraying or splitting.

Calibrating Your Mattress Flanging Machine

All machines have different adjustment settings that allow the manufacturing company to configure a given machine for specific types of mattresses and fabric. Good calibration of such adjustments ensures accuracy and uniformity in stitches.

Calibration Steps for Accurate Stitching

Setting Stitch Length and Width: The thumb rule is to always vary stitch length and width according to thickness or type of fabric. Thicker and heavier fabrics may need longer stitches that will add strength to them, while lighter ones may need shorter stitches in order to give them a fine look.

Adjusting Thread Tension: Thread tension determines whether the stitches will pull evenly. If it is too tight, stitches can pull too hard on the fabric and cause puckering, if it is too loose, seams may be prone to coming apart. Many automatic models boast a digital display for the tension setting of the thread so that this may be fine-tuned with ease.

Aligning the Needle: To avoid seams that are crooked or misaligned, it is important that the needle aligns properly with the path of the stitch. Periodically checking the alignment of the needle will greatly enhance stitch accuracy, especially when changing fabrics or different stitch patterns.

Calibrating Pressure Foot Settings: The pressure foot holds the fabric in place as it feeds through the machine. It should be set so it applies only enough pressure on the fabric to guide it and not create a lot of creases or bunching. Very often, this setting can be set digitally for ease of repetition in consistency.

Conducting Test Runs for Precision

Immediately after the settings with calibration, practice test stitches using sample materials to confirm settings. Check tension, stitch length, and width to make sure they are similar in quality. Testing is crucial, particularly when you are changing materials. Different thicknesses of fabric will perform differently in the machines.

Regular Maintenance for Optimal Performance

The automatic mattress flanging machine requires routine maintenance to guarantee stitching precision over a period of time. A well-maintained machine ensures more consistency in quality, reduces downtime, and prolongs its service life.

Cleaning Thread Pathways and Tension Mechanisms: The threading system of the machine may get clogged up with dust and fabric particles, which can result in inconsistent tensions. Clean thread paths and tension parts regularly to avoid disruption in the thread flow.

Lubrication: Apply lubrication to the needle bar, motor, and pressure foot mechanisms to reduce friction and potential wear and tear of parts. Refer to the guide for recommended oils to be used and the frequency of application.

Belt and Drive System Checks: The drive belt should be checked for any sign of wear or looseness, these affect stitch timing and precision. Periodically, the drive motor should be checked to operate without any particular noise or vibration.

Needle Replacement: The needles that have either become dull or bent from use can affect the quality of the entire stitch. Frequent replacement will keep the needles sharp, preventing damage to the fabric, and it will stitch cleaner and put less stress on the machine.

Operator Training for Precision in Automated Flanging

Even though many functions are automated by the machines themselves, skilled operators are often needed to oversee machine functions, remove defects, and make changes in settings as required. Good training of operators increases overall productivity and stitch quality.

Understanding Machine Controls: Operators should be familiar with the control settings for things such as stitch length, tension adjustments, and automation features. This enables them to make the necessary changes quickly and also extends their versatility with a wide variety of materials.

Material Handling Skills: While most of the feeding of the fabric is done by automatic machines themselves, operators should be able to position and guide fabrics efficiently without wrinkles, creases, and misalignments. Training in handling different types of fabrics helps operators manage various textures and thicknesses.

Troubleshooting Common Issues: Coursework on how to troubleshoot some of the common issues one may face, such as missed stitches, thread breakage, and variation in thread tension. Skilled operators are able to handle these problems in a quick time for more productivity with less downtime.

Inspection and Quality Control: The operators must be provided with inspection training regarding how to check their work to ensure that stitches are of proper quality. Early detection of errors and improvement in the overall quality of the product could be achieved by checking for proper tension, alignment of stitches, and evenness of fabric.

Leveraging Technology for Enhanced Precision

Advanced technology incorporated into today’s automatic flanging machines has the potential to significantly improve stitching accuracy and consistency. Many of the more expensive machines are now fitted with digital monitoring systems, along with automated adjustments that enable the operators to achieve a far superior standard of quality with a lot less human intervention.

Digital Monitoring and Real-Time Adjustments

Digital monitoring systems allow operators to assess stitch quality in real-time, noticing and catching the problem at the instant it happens. For example, sensors may show skipped stitches, improper thread tension, or bunching fabrics to the operators, after which there is the ability to make instantaneous corrective adjustments.

The monitoring systems can also save machine settings for different fabrics so that whenever a similar production runs, the process of setup and calibration becomes easier and faster.

Automation for Precision Stitching

The stitch length and width on some high-end machines can be automatically adjusted depending on the type of fabric and its thickness. Automation minimizes most errors caused by manual stitch adjustment. This would be especially helpful if one had to work with several types of fabrics in a high-volume setting. These features save time and improve consistency, especially for large batches.

Conclusion

Achieving precision with an automatic mattress flanging machine is a multi-step process involving calibration, maintenance, training, and technology. By following these practices, manufacturers can produce mattresses with consistent, high-quality seams that enhance both durability and aesthetic appeal.

From initial setup to ongoing maintenance and operator expertise, every part of the process contributes to a product that meets or exceeds industry standards. Integrating advanced technology into your process further optimizes stitching quality and enables efficient, high-volume production with reduced error rates.

Связанные с ними товары