- Home » How to Choose the Right Tape Edge Machine for Your Mattress Business

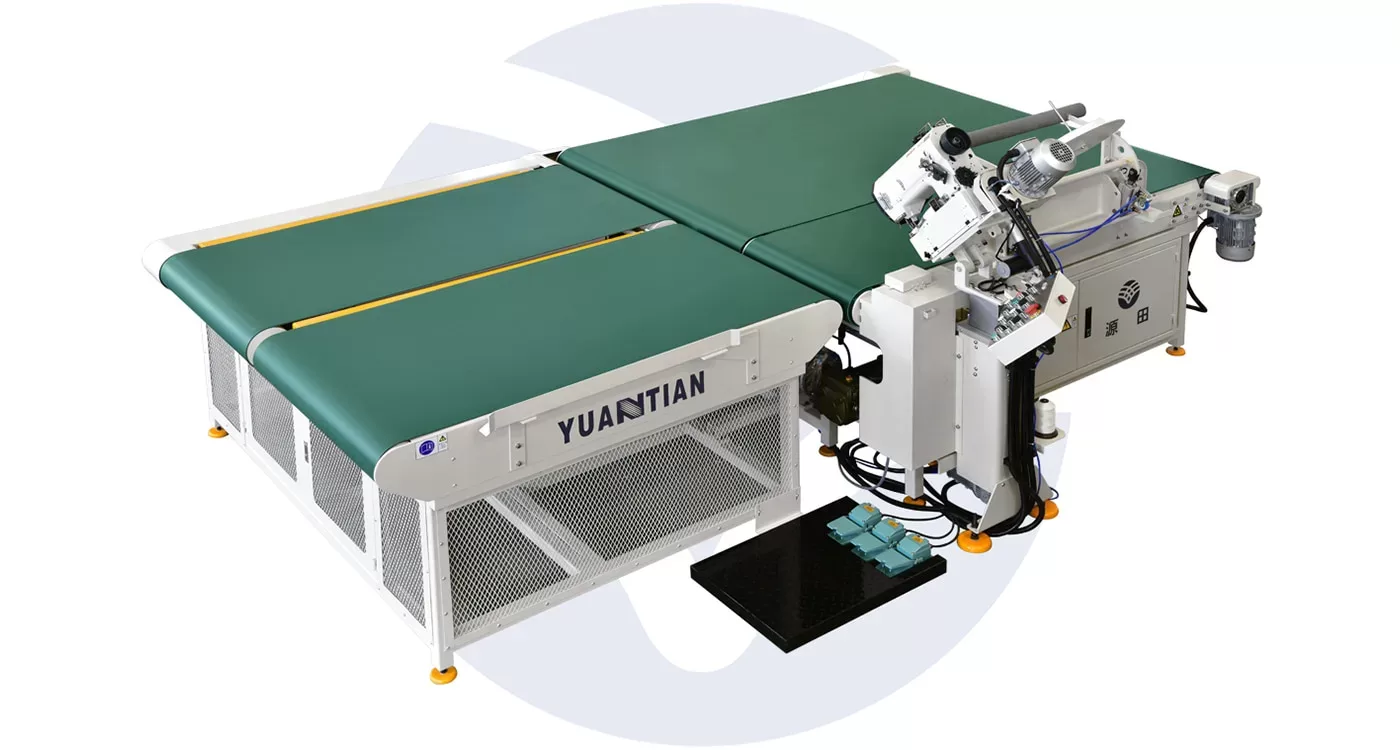

In the mattress manufacturing industry, the tape edge machine is a critical piece of equipment that plays a key role in finishing mattresses. By sewing the top and bottom layers of the mattress, it ensures a tight, durable seal that enhances product quality and longevity. Selecting the right tape edge machine for your mattress business can significantly impact production efficiency, product consistency, and overall profitability.

With various models available, each offering different features and benefits, understanding how to choose the best one for your operation is essential. This article will guide you through the factors to consider when selecting a tape edge machine for your mattress manufacturing needs.

Understanding the Role of a Tape Edge Machine in Mattress Production

What is a Tape Edge Machine?

The tape edge machine is a specialized piece of equipment designed for stitching borders on mattresses. This sews the top panel/ bottom panel with the quilted sides of the mattress together by using binding tape to secure layers and give a finished appearance to the mattress.

The process constitutes one of the last stages in mattress manufacture and is of prime importance from both aesthetic and structural standpoints. A well-sealed mattress edge ensures durability, reduces the risk of fraying, and helps maintain the shape and comfort of the mattress over time.

The Importance of Choosing the Right Machine

The choice of a tape edge machine can greatly affect the quality of the finished product, production speed, and overall operational efficiency. A high-quality machine will ensure a strong, even stitch and can handle various mattress sizes with ease.

On the other hand, a faulty or inferior machine can lead to various problems, such as production delay, increased maintenance, or variations in stitching that can affect customers’ satisfaction and create expensive returns or repairs.

Key Factors to Consider When Choosing a Tape Edge Machine

Type of Machine

In general, there are three types of tape edge machines: manual, semi-automatic, and automatic. Which is suitable for your business is dependent on the scale of operation, budget, and the required level of automation.

Manual tape edge machines require the operator to manually guide the mattress as it is sewn. While these kinds of machines are generally cheaper, and may also produce results of higher quality, they demand skilled manpower and are more time-consuming. The case may be that, for smaller manufacturers or businesses with limited production volume, a manual machine could be cost-effective.

Semi-automatic tape edge machines bridge the gap between manual and automatic systems. These machines typically require some operator intervention but come equipped with features that enhance efficiency and ease of use. Semi-automatic machines can provide improved consistency and speed over manual machines while being easier to operate and maintain.

Automatic tape edge machines are less demanding of their operator. Their automation capabilities allow for the continuous movement of the mattress, through stitching, which generally increases speed, accuracy, and consistency. Automatic machines are very ideal for those high-volume production facilities where efficiency and reduction of labor costs become primary concerns. However, they are burdened with higher upfront costs and may necessitate specialized training among operators.

Speed and Efficiency

Another important consideration is the operating speed of the tape edge machine. This applies to companies with large volumes of production. Machines are rated according to the amount of mattresses they can stitch within an hour. High-range automatic machines stitch up to 100 mattresses within an hour and will be a good choice for large manufacturers who are determined to catch up with high demand.

For smaller businesses or those with a specialty in custom or luxury mattresses, speed may not be as important. Precision and flexibility perhaps outweigh the question of output.

Mattress Size and Material Compatibility

Different tape edge machines are meant to handle various sizes of mattresses and different materials. With a company producing such a wide range of mattress types from standard foam to hybrid to pillow top design, these machines must have the ability to handle such diversities.

It’s important to make sure that the machine itself can work with your materials. For example, thicker mattresses may require higher clearance while tougher fabrics-more common with high-end mattresses-would need more heavy-duty stitching parts to be able to push through the added resistance.

Adjustability and Flexibility

A good tape edge machine must provide a degree of adjustability that will enable your operators to vary some settings: sewing speed, stitch length, and tension. This becomes helpful in case your business handles a variety of mattress types or even orders for custom mattresses that require different techniques of finish.

Having machines with easy adjustment can maximize workflow and avoid downtime in switching to other machines for different sizes of production runs. Other machines also have work tables or heads that tilt, so handling mattresses of all shapes and sizes is easier to handle by operators.

Durability and Maintenance Requirements

Every mattress manufacturer should invest in a long-lasting machine. Since the tape edge machine is a long-term investment, its reliability is important in influencing your uptime operation. Machines with high-quality components, such as industrial-grade motors and parts, will have longer life spans and fewer repairs throughout their lifetimes.

Also, consider what maintenance the machine requires. Although some machines require frequent greasing or replacement of parts, this has the potential to cause breakdowns quite often, which will decrease productivity and enhance the operating cost. Opt for a machine that has a history of low maintenance, or one that provides a very solid warranty and technical support that is easily available. This will reduce the likelihood of an unexpected breakdown.

Training and Support

The best machine available cannot function any better than the person operating it. Any time a tape edge machine is being considered, training and follow-up technical support are concerns to be taken into consideration. Particular automatic machines may need experience with their operation and maintenance. In this respect, most manufacturers provide programs for training or at least provide a well-detailed user manual so the operator can effectively learn to operate the machine safely.

Besides that, dependability for after-sales support. Make sure the supplier provides very good technical support, easy availability of spare parts, and timely maintenance service. This will ensure minimum chances of downtime and hassle-free, continuous production.

Budget and Long-Term ROI

While it is very tempting to look at only the initial cost, considering long-term return on investment is a vital factor in choosing a tape edge machine. Those machines which come in the cheaper category may save money for an individual initially, however, they are higher when it comes to maintenance cost, productivity is reduced, and their life is very short.

Conversely, investing in a good quality and highly efficient machine results in savings in the long run due to improved durability, low operating costs, and enhanced productivity.

Assess your budget carefully, and weigh that against the potential of the machine to enhance your general production efficiency and to cut down on labor costs. Consider how quickly the machine will pay for itself in terms of increased output, reduced labor, and minimized downtown.

Conclusion

Choosing the right tape edge machine for your mattress business is a critical decision that can influence your production speed, product quality, and operational costs. By considering factors such as the type of machine, speed, compatibility with mattress sizes and materials, adjustability, durability, and budget, you can make an informed decision that aligns with your business needs.

Whether yours is a small custom mattress shop or a large-scale manufacturing operation, the right tape-edge machine can help not only improve your production process but also ensure product quality consistency crucial to business success.

Связанные с ними товары