- Home » How to Achieve Consistent Results with a Mattress Tape Edge Machine

Consistency and quality are the premises of any manufacturing process of mattresses, which meets customer expectations and provides a competitive edge. One of the most critical places in the process flow is held by the tape edge machine, stitching the top and bottom panels to the border fabric of the mattress with tapes of special design.

Consistent performance from this machine ensures that every mattress has a clean, professional appearance and a durable edge that withstands long-term use. Achieving consistent results with a mattress tape edge machine requires a combination of proper machine setup, operator training, regular maintenance, and quality control procedures. This article explores the steps and best practices for maintaining consistent results with a mattress tape edge machine.

Understanding the Tape Edge Machine and Its Function

The Role of a Tape Edge Machine in Mattress Production

The tape edge machine glues the outer edges of the mattress, fastening the top and bottom layers to the side panel with fabric tape. This is usually the final stage in mattress assembly, hence a very crucial part regarding the overall durability and appearance of the final product. Here, several layers of fabric and padding are stitched by this machine to provide a strong bond inhibiting the layers from shifting or separating during use.

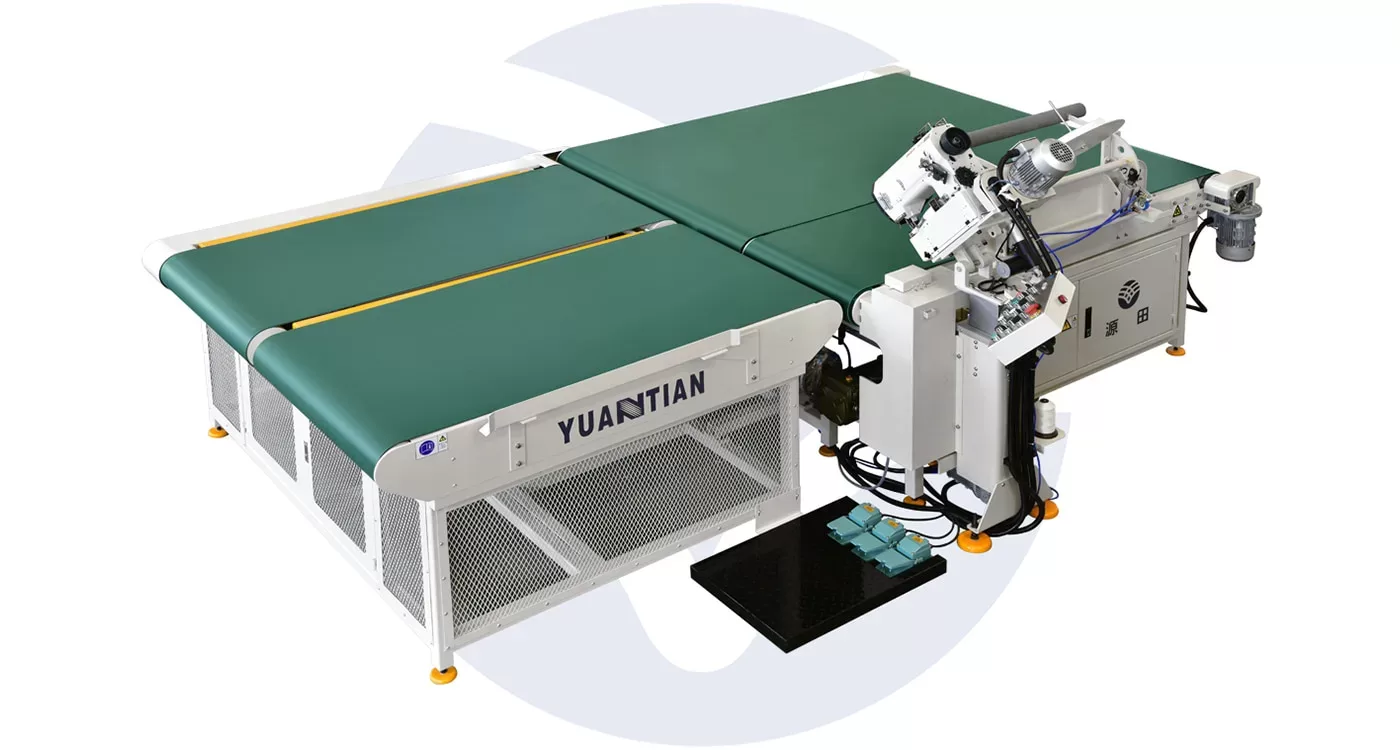

These tape edge machines will be designed to handle a variety of thicknesses of fabric, padding, and upholstery. Therefore, the machines are capable of sewing straight and curved lines, ensuring that mattresses in all shapes and sizes can be worked on.

Because this is one of the final steps in the production process where precision is important, this tape edge machine will also play a vital role in establishing consistency for professional-grade mattresses of high quality.

Types of Tape Edge Machines

There are several types of tape edge machines for different scales of production and mattress styles. Here are the main types:

Manual Tape Edge Machines: The mattresses have to be moved by hand along the stitching path by the operator. Although these machines offer flexibility and control advantages, they are slower and highly dependent on the operator’s skills.

Semi-Automatic Tape Edge Machines: These machines offer a more extensive level of automation, such as automatic foot-lifting and variable speed control, whereby the operator is required only to guide the mattress, the machine performing the stitching operation.

Fully Automatic Tape Edge Machines: These are high-volume, high-speed models intended for the most demanding production requirements but can be operated with very little manual input. Mattress movement and stitching are performed automatically for faster, uniform results with a minimum amount of variation.

The type of machine that will be used will influence how consistency is achieved, but regardless of the type of machine employed, certain practices must be employed in order to ensure reliable performance.

Key Factors for Achieving Consistency with Tape Edge Machines

Proper Machine Setup and Calibration

The first step in achieving constant results with a mattress tape edge machine is to ensure the proper setup and calibration of the machine for any given production run. Proper setup should include adjustment of the machine with regard to material types, such as thickness of fabric and padding, and tape itself.

Correct tension in the thread is of utmost importance to achieve even stitching without skipped stitches or threads broken apart. If too tight, it may snap or pucker on the fabric. If too loose, stitches will be weak and open sometime later. Always check the tension and adjust it according to the specific materials used on every mattress.

The compatibility of the needle with the thread to be used is imperative. Thus, when sewing thicker fabrics or when working with several layers, one may need a more substantial heavy-duty needle or a strong type of thread so that the machine can keep up its capability of sewing without any problems.

The feed mechanism governs the smoothness by which the mattress negotiates its way through the machine. Poor feeding can also lead to a number of uneven stitching, gapping, or skipped stitches. Check the feed dogs (that part of the machine that pulls the fabric through) are at the right speed and height for mattresses being manufactured.

Operator Training and Skill Development

Even the best machinery requires knowledgeable operators for consistent results. With a tape edge machine, one must understand the mechanics of the machine and know how to make the necessary adjustments to the machine. Operator training is of most importance, which ensures each mattress is stitched to exactly the same high standard.

Operators need the ability to maneuver the mattress through the stitch path without puckering or uneven tension. This requires, on manual and semi-automatic machines, the careful manipulation of the mattress around both straight and curved edges while maintaining control over machine speed and direction.

Operators are supposed to pay great attention to the quality of every stitch, ensuring the good operation of the machine and that some definite skips in the sewing pattern do not appear. In this way, through early detection of a probable problem Thread breakage or misalignment of fabric, defects can be avoided and all products will keep uniform quality.

Operators should be able to diagnose and solve machine problems when they occur. For instance, being aware of whether the needle needs replacement, if the tension of the thread needs adjustment, or if the machine needs recalibration, will help maintain consistency.

Regular Maintenance and Inspection

In this regard, the tape edge machine has to be serviced regularly for it to perform its functions with efficiency and predictability in the production cycle. Over a long period of time, the machine components will go through wear and tear conditions, which eventually breed potential problems with the stitching defect, lengthened machine downtime, or even damage to the mattresses being made.

Routine lubrication ensures friction reduction, therefore not allowing the wear and tear of any moving parts of the machine. A well-lubricated machine will move with fewer problems and, as such, is not prone to mechanical issues that may affect stitching quality.

A very important factor is to check needles and threads from time to time because they do wear out. Crooked threads or pointed needles don’t stitch properly, which might affect the finished product by giving uneven stitches. Therefore, replacement before malfunction must be done in order to meet proper quality control.

Due to such factors as time, vibration, and normal use, parts of the machine may shift slightly and affect how the mattress is fed through the machine. Ensuring everything is properly aligned keeps stitching consistent from one mattress to the next. Regularly checking the alignment and calibration of the machine will keep the path of stitching accurate.

Implementing Quality Control Measures

In-Line Quality Checks

In-line quality checks during production assist in the early detection of some problems, preventing the buildup of defects. For the tape edge machines, operators or quality control personnel should occasionally inspect stitching for conformance to company standards.

The stitching should be periodically inspected for consistency in tension, even spacing, and secure edges. Evidence of skipped stitches, loose threads, or puckering would serve as notice of possible machine or operator faults.

Ensure that the mattress edges are correctly aligned and the tape is correctly applied across all sides of the mattress. A misaligned edge or incorrect uneven taping will affect both the looks and durability of the mattress.

Reinspect the mattress again for defects that might have been missed in production before packing, regarding tape edge stitching of the mattress.

Data-Driven Adjustments

Data-driven systems can optimize automation for a manufacturer by using fully automated or semi-automatic machines. It will monitor machine performance and stitching quality, and warn operators of impending irregularities well in advance of such occurrences so that defective goods can be avoided. From the data analysis, changes can be made to get a more consistent product while reducing the waste of materials.

Conclusion

Achieving consistent results with a mattress tape edge machine is critical for producing high-quality mattresses that meet consumer expectations. Consistency depends on several key factors, including proper machine setup and calibration, skilled operators, regular maintenance, and stringent quality control measures.

By investing in training, staying proactive with maintenance, and using data to optimize production, mattress manufacturers can ensure that every product meets the same high standard of quality. As a result, companies can improve efficiency, reduce waste, and maintain a strong reputation in the competitive mattress market.

Связанные с ними товары