- Home » How Precision Tape Edge Machines Help Reduce Waste in Mattress Manufacturing

Waste reduction has become a key objective for manufacturers across various industries, and mattress manufacturing is no exception. In today’s increasingly sustainability-driven marketplace, consumers expect eco-friendly products and processes, while businesses seek to reduce costs and boost profitability. One of the most significant innovations in mattress production is the use of precision tape edge machines.

These machines have revolutionized the way mattresses are made by improving efficiency, ensuring product consistency, and most importantly, minimizing material waste. In this article, we will explore how precision tape edge machines contribute to waste reduction, how they function, and why they are an essential tool for modern mattress manufacturers.

Understanding Tape Edge Machines

What Are Tape Edge Machines?

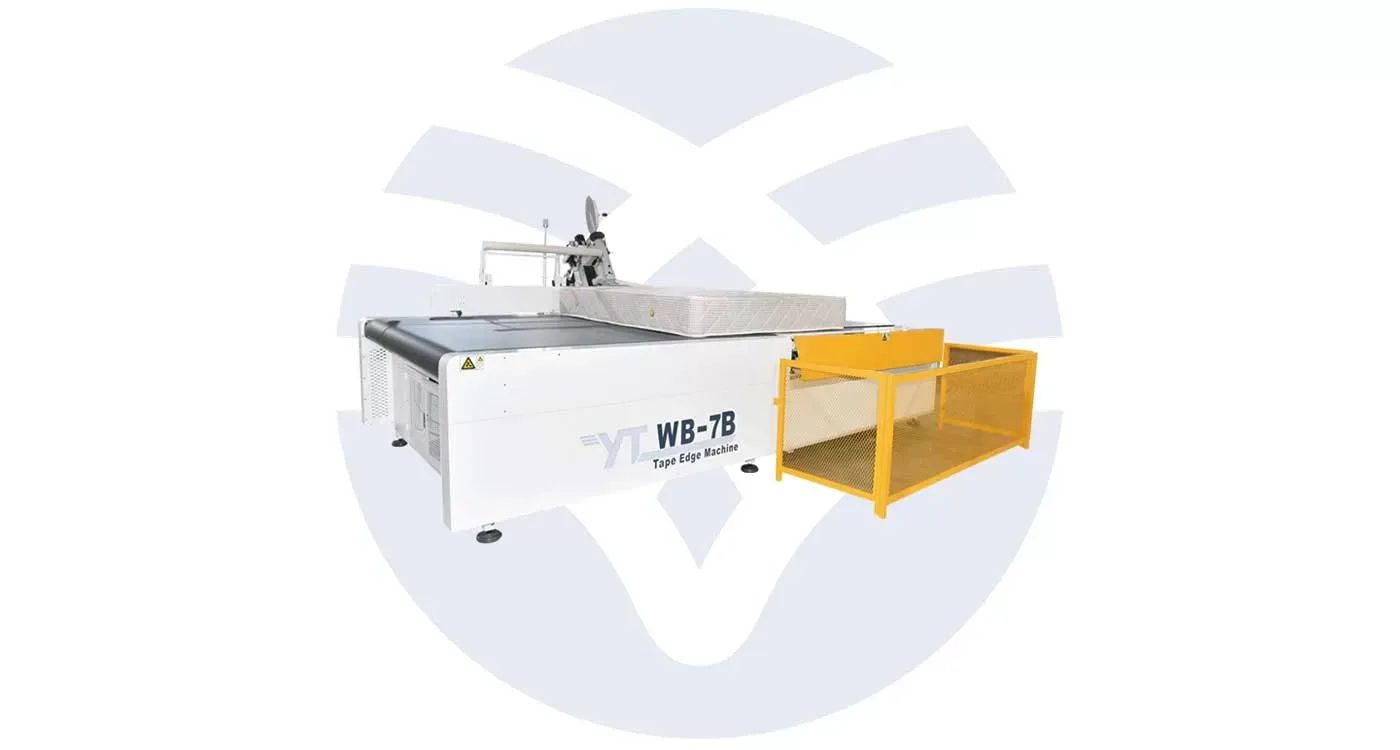

Tape edge machines are specialized pieces of equipment used in the final assembly of mattresses. These machines put a tape-like material, commonly made of fabric, onto mattress edges to seal it tightly. Not only does this increase the durability of the mattress but also makes it more attractive. The tape holds the top and bottom panel edges down against side panels to prevent any damage for a longer life of the mattress.

This has conventionally been performed by hand in more traditional mattress manufacturing, or with the use of semi-automatic machines. While generally effective, these can be inconsistent, use too much material, and create a high number of reworks. With precision tape edge machines, manufacturers have been able to greatly enhance both quality and efficiency for this process.

Types of Tape Edge Machines

These tape edge machines come in a lot of different types with their respective production requirements: from entirely manual machines, where the operator’s skill and control are a major determinant of quality output, to semi-automatic machines, wherein partial automation is available but still heavy human intervention is required; up to fully automatic, precision machines capable of covering the whole process with just a few operators.

Precision tape edge machines are among the latter and represent the most advanced technique in the industry. These machines provide ideal levels of control over the application of the tape, ensuring it is applied consistently and evenly with minimum waste.

How Precision Tape Edge Machines Minimize Waste

Reduced Material Usage

The key ways that precision tape edge machines reduce waste in mattress manufacturing include optimization of material usage. Most traditional methods involve manual cutting and sewing, during which too much fabric is used due to measurement or technique errors. These precision machines, on the other hand, are programmed to apply the exact amount of tape that each mattress will require, thus minimizing excess material usage and reducing scrap fabric.

This, in turn, reduces the possibility of some of the errors leading to overuse or underuse of materials due to the application of the correct amount of tape with high accuracy. The machines are usually able to seal the edges consistently, which means less requirement for rework, which again helps in material conservation.

Fewer Defects and Rework

The defects in the final product constitute a great source of waste in every form of manufacturing, and mattress production is no exception. Inconsistencies in stitching and uneven tape applications, misaligned seams, are all common instances of mattresses having defects that would need to be reworked or even discarded. Precision tape edge machines reduce drastically the possibility of these defects occurring.

Equipped with advanced sensors and automated controls, these machines ensure that each mattress is finished to the most exacting standard. The tape is laid evenly across the complete edge of the mattress, and the likelihood of anomalies such as loose threads or uneven seams is practically nil. This reduces defect rates for manufacturers, therefore reducing the number of mattresses needing repair or scrapping saving both materials and labor.

Improved Production Speed and Efficiency

One of the key benefits of precision tape edge machines is that they tend to ensure that production becomes smoother. Through automation, the edges of mattresses can be taped at a much quicker pace, which will allow manufacturers to make more within a certain time. Thus, an increase in efficiency will relate directly to less waste because faster production reduces bottlenecks and reduces the idle time of materials to minimize the possibility of degradation or spoilage.

They also eliminate human error, which is often considered one of the highest contributing factors to material waste in a manual or semi-automated process. Since precision machinery requires very minimal human touch, the chances of errors such as misaligned tapes, uneven stitches, or even excess cutting of fabric, are significantly reduced. Consequently, more mattresses are produced correctly on the first try, reducing the need for additional resources to fix mistakes.

Supporting Sustainability Initiatives

Aligning with Eco-Friendly Goals

Sustainability is not just a buzzword, but the most important leg of corporate responsibility in today’s business environment. Most mattress manufacturers have been applying eco-friendly practices and trying to cut down on waste in their efforts to minimize environmental impacts. In this respect, precision tape edge machines come into great play.

Also, they help the manufacturer reduce his intake of resources altogether by decreasing material waste. Since only a few products produced are defective, the amount of waste that reaches landfills is reduced accordingly. This meets the demand of consumers who increasingly require green products and processes. This advantage gives the manufacturer an edge over its competitors in the market.

Reducing Energy Consumption

Precision tape edge machines are also energy-efficient compared to their manual or semi-automatic predecessors. Since the operation of these machines at high levels of accuracy and speed tends to be characterized by lower energy consumption per mattress produced, the long-term effect on a firm’s carbon footprint acts to further enhance the sustainability of mattress manufacturing operations.

Besides, this automation machine can be applied to a larger energy-saving strategy, like the optimization of manufacturers in production scheduling to reduce the idle time of the machinery and the usage of the total operation energy.

Conclusion

Precision tape edge machines play a vital role in reducing waste in mattress manufacturing. By optimizing material usage, reducing defects, improving production efficiency, and supporting sustainability initiatives, these machines help manufacturers meet both economic and environmental goals. As the industry continues to evolve, adopting advanced machinery like precision tape edge machines will be crucial for companies looking to remain competitive, profitable, and environmentally responsible.

Связанные с ними товары