- Home » How Pocket Spring Row Cutting Machines Optimize Assembly Processes

In the fast-paced world of manufacturing, efficiency and precision are crucial for maintaining competitiveness. One area where these factors are particularly significant is in the production of pocket springs, which are widely used in the mattress industry. Pocket spring row cutting machines have emerged as a game-changing technology, enhancing the assembly processes involved in pocket spring production.

Introduction to Pocket Springs

What Are Pocket Springs?

Pocket springs are the spring units individually wrapped in fabric pockets. Since each spring is independent, it supplies more specific support and minimizes bounciness or movement between people who share a bed. Such a design has made pocket springs popular with high-quality mattresses for comfort and durability.

The Role of Pocket Spring Row Cutting Machines

Pocket spring row-cutting machines are designed for the production of pocket spring units. The machines perform a fully automated function in cutting, hence achieving correct dimensions and quality every time. Such machines would be valuable in any assembly line manufacturing process because of greater productivity and cost efficiency.

The Mechanism Behind Pocket Spring Row Cutting Machines

How the Machines Work

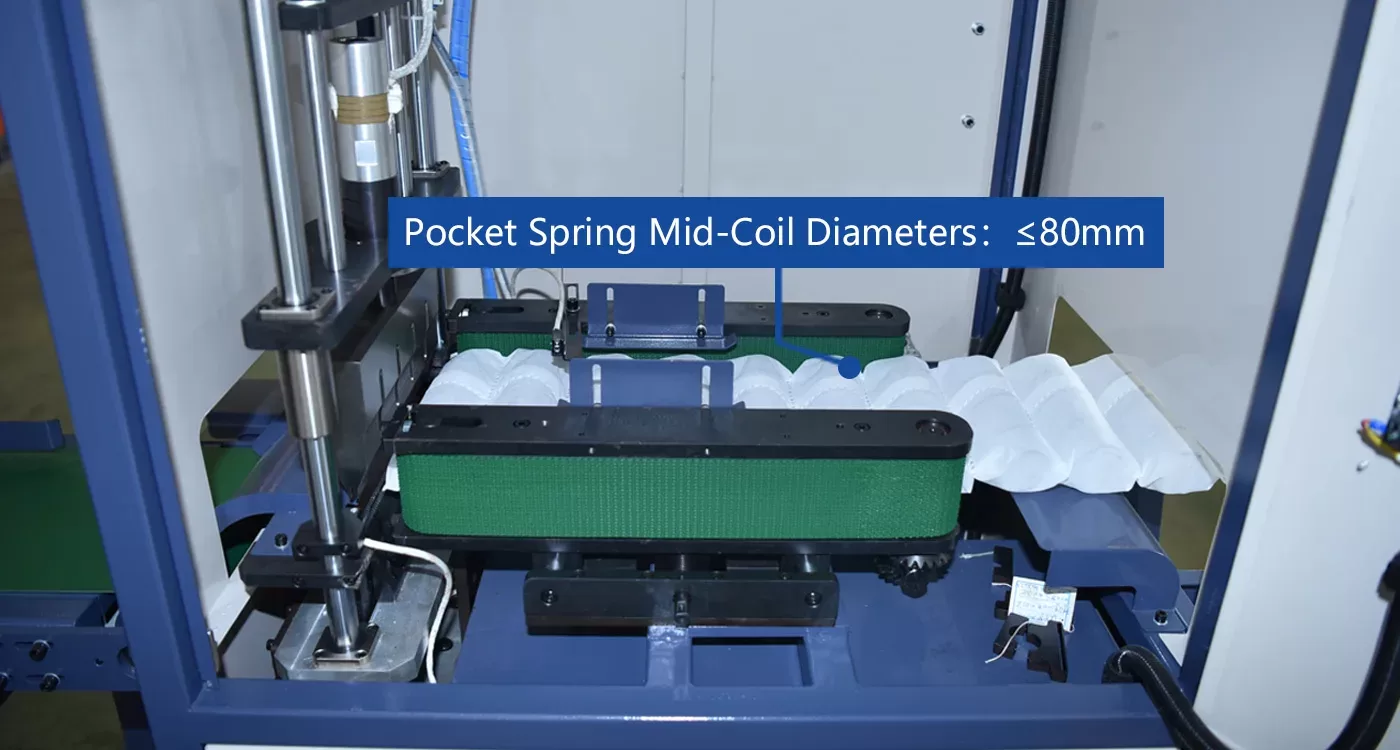

Pocket spring row-cutting machines are fitted with highly developed cutting technologies; most of the time, they employ blades capable of cutting several layers of fabric and springs simultaneously. The capability underlying this approach ensures that components are to length with a minimum of waste.

Feeding Mechanism: The machine will carry out an automatic feeding mechanism whereby the pocket spring rows will be conveyed to the area of cutting. Sensors detect the length to guarantee every cut made is accurate to the given length.

Cutting Process: It involves the use of very high-speed blades that provide the cut with the actual and pre-set measurements. Computer numerical control technology incorporation provides for exact specifications, hence reducing the margin of error.

Output and Quality Control: After the cutting operation, the springs are automatically sorted and fed into the next stage of assembly. Quality control monitors ensure through sensors that the outputs are the best qualities for the next phase.

Technological Advancements

Recent developments relating to pocket spring row-cutting machines have enabled features such as:

Laser Cutting Technology: This provides greater precision and cleaner cuts, very important for maintaining the integrity of the springs.

Smart Technology Integration: Imbued with IoT capability, it enables real-time monitoring and data analysis for optimization of production schedules and maintenance.

Benefits of Pocket Spring Row Cutting Machines

Increased Efficiency

The pocket spring row cutting machines brought considerable improvements in operational efficiency. Automation of the cutting process now allows manufacturers to:

Reduce Labor Costs: The manual cutting requires fewer workers, and this should enable the company to use available resources elsewhere in production.

Increase Production Speed: Automatic machines have a greater speed compared to manual processes. That is, more in the same period of time.

Enhanced Precision

One of the main advantages of pocket spring row cutting machines is that they can repeatedly achieve a correct cut. This is a high level of precision that ensures that at the time of assembly, the springs would perfectly fit into their respective pockets.

Minimized Waste: Accurate cutting reduces material waste, which is essential for cost control in manufacturing.

Consistency in Quality: Automation of processes yields consistent results, hence higher quality and reduced defective products.

Improved Safety

It brings about good workplace safety while automating the cutting process. Traditional cutting methods include several risks, like:

Injury from Manual Cutting: During manual operations, the worker is exposed to sharp blades and heavy materials.

Ergonomic Risks: Repetitive manual cutting can lead to injuries over time, impacting worker health and productivity.

Pocket spring row cutting machines reduce injuries to a great degree and, therefore, make the workplace much safer.

Implications for Assembly Processes

Streamlining Assembly Lines

Pocket spring row cutting machines perfectly integrate into current assembly lines, thereby making production smoother. Advantages of the machine include:

Reduced Assembly Time: Since the correct cut in springs made the work of assembly workers easy, all parts just went into their respective pockets in no time.

Improved Coordination: This kind of automated machine can be integrated with other production machinery, facilitating smoother transitions between successive stages of manufacturing.

Scalability

With the continuous demand for pocket springs, their manufacture should be effectively done. It is in regard to this that the pocket spring row cutting machines offer:

Flexible Production Capacity: This flexibility in size and number of springs allows a manufacturer to quickly respond to changes in the marketplace.

Consistent Output: The ability to maintain high production levels without sacrificing quality ensures that companies can meet customer demands reliably.

Cost-effectiveness

Investing in pocket spring row cutting machines can lead to long-term cost savings. Factors contributing to cost-effectiveness include:

Lower Material Costs: Reduced waste and improved cutting precision result in lower material expenditures.

Enhanced Productivity: Increased output leads to higher revenue potential, which can offset the initial investment in machinery.

Conclusion

Some of the innovations that have taken place in mattress assembling include pocket spring row-cutting machines. Indeed, efficiency is boosted, precision ensured, and safety considerably achieved when this equipment is used, thus offering a competitive advantage to manufacturing companies.

As demand for pocket springs increases, it will be required of companies to adapt to automated cutting solutions. Optimizing the assembly processes enables manufacturers to ensure they can deliver quality products at minimal costs by maximizing productivity.

Связанные с ними товары