- Home » How Modern Mattress Quilting Machines Improve Production Flexibility

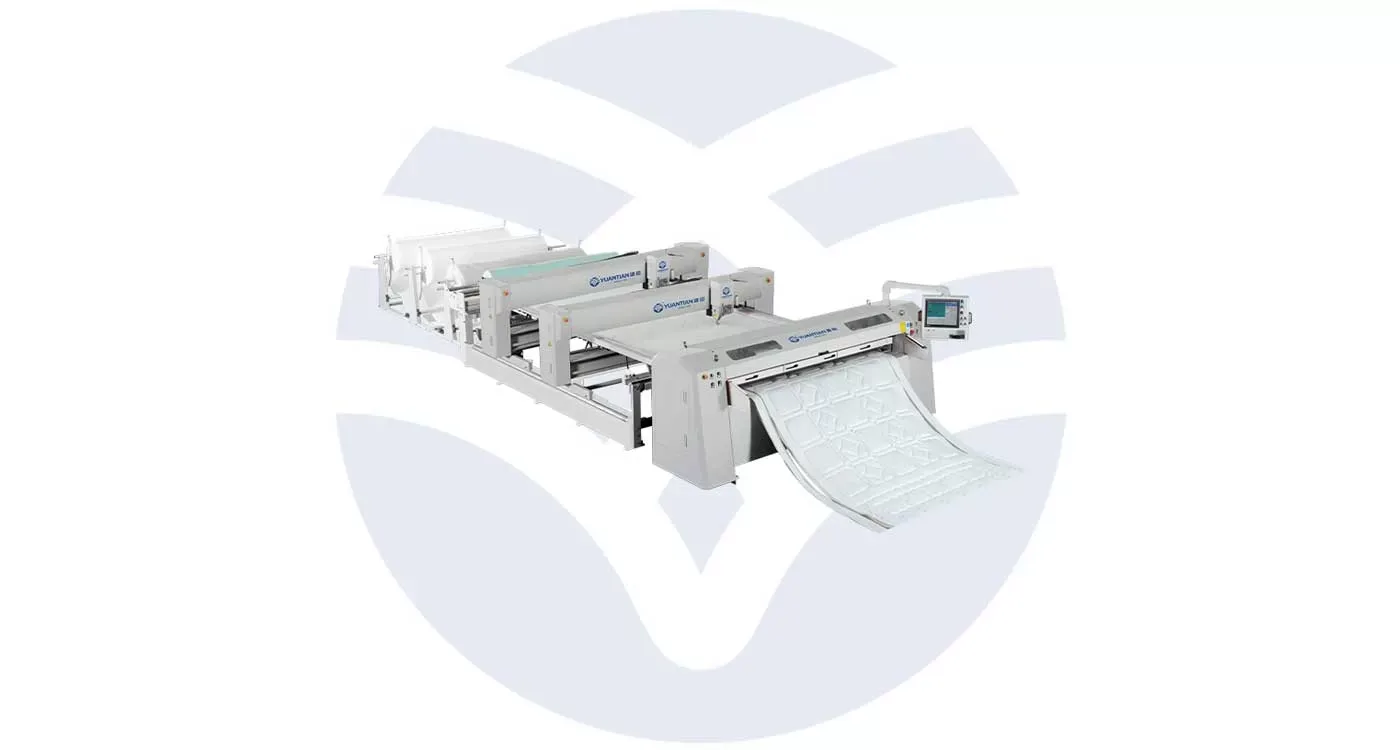

Mattress manufacturing has seen remarkable advancements over the years, especially in the realm of quilting, which plays a vital role in the overall comfort, appearance, and durability of the product. With the introduction of modern quilting machines, manufacturers are now able to achieve greater flexibility in their production processes.

These innovations not only streamline production but also allow for higher levels of customization, improved quality, and cost-efficiency. This article explores the ways in which modern quilting machines enhance production flexibility through automation, design versatility, and material management.

Automation: Streamlining the Manufacturing Process

The most overwhelming development in modern mattress quilting machines is the application of high-level automation. Automation has made the traditional process of mattress quilting from being very labor-intensive into a very efficient, accurate, and disputable activity.

Reducing Manual Labor

Traditionally, it always took skilled laborers to feed the layers of fabric manually between the mechanical machines to carry out the quilting process. Such skills were very time-consuming and always prone to errors.

In this modern era of quilting, machines are capable of carrying out this skill on their own with the incorporation of computerized machinery. Instead, these machines use pre-programmed patterns to stitch the fabric with the least human labor involvement, reducing manual labor to a great extent.

Enhancing Precision and Consistency

Automation also enables more accuracy and consistency of the stitch patterns in quilting. Modern quilting machines are equipped with a computerized control system that works to achieve uniformity in stitch patterns and complicated designs. Precision thus guaranteed reduces chances of defect generation, enabling every single mattress to live up to high standards. Moreover, a limited role played by human operators reduces variability in production, which again leads to consistent product quality even in large batches.

Speeding Up Production Times

By automating the more monotonous and repetitive tasks, the modern quilting machine is able to perform at much faster speeds than its ancestors. Take, for example, those computer-controlled quilting machines that can stitch in highly intricate patterns at speeds no human operator can beat. The higher the speed, the sooner the production, therefore, it also meets the demand that is considered to be high without compromising quality.

Design Versatility: Expanding Customization Capabilities

Consumer preference for mattresses has become diversified. The trend of insisting on personalized products has increased. Mattress quilting machines are able to permit greater flexibility in pattern, texture, and type of fabric to be used, considering the consumer tastes that range across a wide spectrum. This is the versatility in design that enables manufacturers to provide mattresses functional and pleasing to consumers’ eyes.

Custom Quilting Patterns

One of the most astounding things about quilting machines in today’s world is how customized patterns can be created so quickly and easily. From traditional floral designs to more modern geometric patterns, higher-end quilting machines can be programmed to undertake just about any design with perfect accuracy. This is going to be somewhat important for those manufacturers who seek to offer differentiated products or appeal to certain niche markets that have unique demands with regard to specific designs.

Multi-Needle Quilting for Complex Designs

Another capability of modern machines is multi-needle quilting. As good as this may be for intricate designs that call for multiple stitching passes, this capability can further cut into production time with such a high level of detail and accuracy. The ability to do complicated quilting in one pass enables the manufacturer to expand its portfolio of designs without sacrificing efficiency in doing so.

Variety in Fabric and Material Compatibility

These quilting machines of today also accommodate a wide range of fabrics and materials, ranging from traditional cotton to the latest high-tech memory foam covers. These machines can stitch through different layers of various thicknesses. Due to this flexibility, manufacturers can use a lot of different materials in designing their mattresses for customers.

But it is also because modern machines can be adapted for so many different types of fabrics that manufacturers can keep up with the ever-changing trends in mattress construction, such as the increasingly popular hybrid materials.

Material Management: Improving Efficiency and Reducing Waste

Another important factor in production flexibility is material management. Modern quilting machines make valuable contributions to this with regard to material usage, waste minimization, and cost-effective and environmentally friendly production.

Minimizing Fabric Waste

Keeping waste to a minimum is not that easy when manufacturing mattresses, specifically when producing complex quilt patterns. Older machines for quilting required extra material for wasteful manual stitching processes and resulted in excess scrap fabric. This modern software can perform advanced calculations simply to use exactly enough material for every quilted pattern. Not only does that minimize waste of material, but it ultimately economizes production by optimizing the consumption of fabric.

Automated Material Feeding Systems

Modern quilting machines have material feeding systems that guarantee perfect alignment of the fabric layers, this ensures a minimal chance for any errors or slippage of the materials. This automated feeding eradicates frequent manual adjustment, hence offering a smoother, quicker, and much more efficient production flow. Besides this, an automated material feeding system avoids bottlenecks on the production line since the quilting phase will never be the limiting link in overall production capacity.

Integration with Other Production Processes

Most of the recent quilting machines have been designed to interface well with other machines, such as cutters and assemblers. This ensures continuity in production, reducing the idle time between stages, and the material will quickly move through a line of production. The result will be a more integrated operation in which different processes are seamlessly integrated to enhance total productivity and flexibility.

Advanced Software: Enhancing Control and Monitoring

Other factors contributing to higher production flexibility of quilting machines include the installation of sophisticated software systems in modern quilting machines. These software systems ensure that manufacturers have full control over the quilting process and can monitor the operation of the machine in real-time.

Easy Pattern Programming and Adjustments

Newer quilting machines boast systems for control, where operators can apply and alter programmable patterns for quilting. Some have preloaded templates of the most common designs and allow for new, customized patterns to be designed and then uploaded into the memory. The changes on the fly will enable the manufacturers to switch to different designs quickly and well.

Real-Time Monitoring and Diagnostics

In fact, even today, software integrated into quilting machines enables operators to monitor and track the quilting process in real time: sewing speed, fabric tension, and needle movement.

In case something goes wrong, the system will be able to give some diagnostic information so that a technician will be able to address the problem without wasting much time or causing disruption to production. Thus, this proactive monitoring allows maintenance of high productivity and reduces disruptions in the production process.

Conclusion

Modern mattress quilting machines have significantly enhanced production flexibility by integrating advanced automation, offering design versatility, improving material management, and incorporating sophisticated software controls.

These innovations have transformed the mattress manufacturing industry, enabling companies to produce higher-quality products more efficiently, while meeting diverse consumer demands. As technology continues to advance, the flexibility and capabilities of quilting machines will only expand further, driving continued growth and innovation in the industry.

Связанные с ними товары