- Home » How Mattress Quilting Machines Handle Various Fabric Types

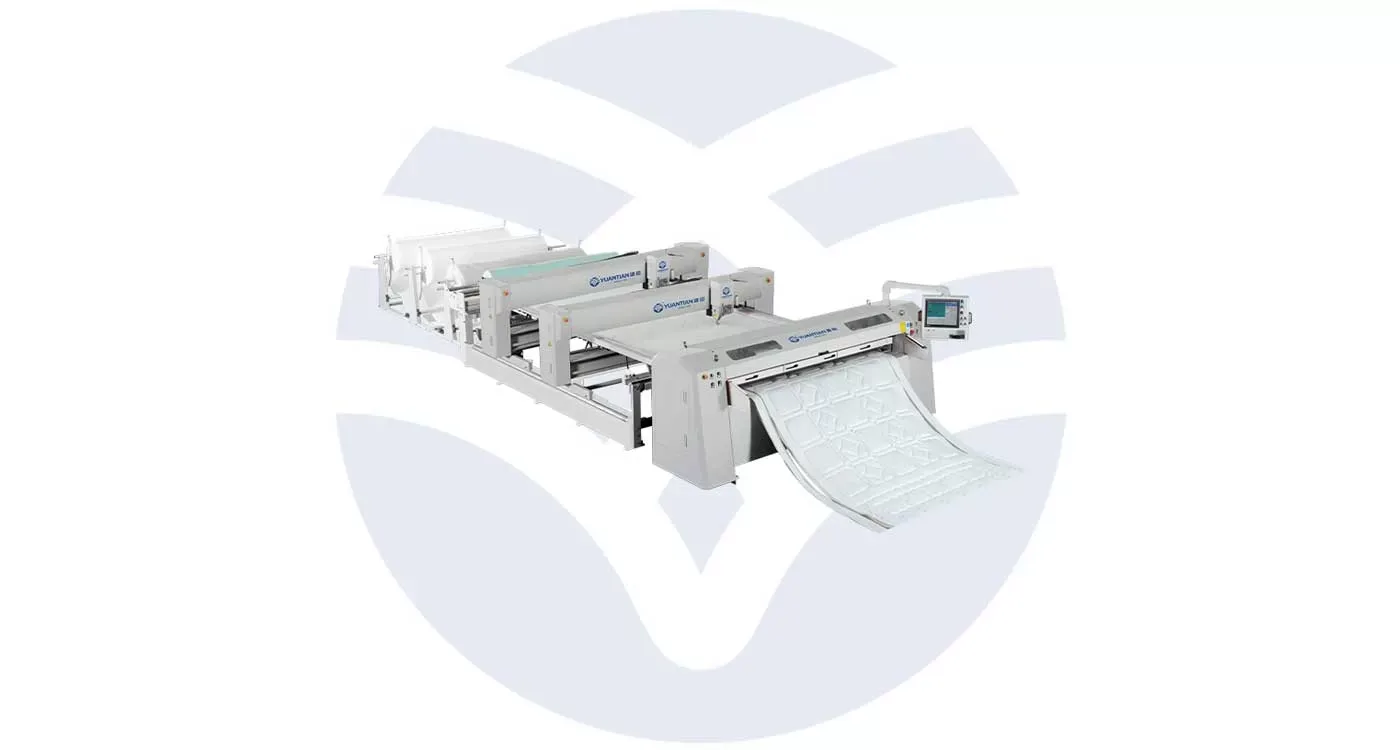

The quilting machine for mattresses is an important productive article needed within the bedding industry for the creation of mattress decorative and functional layers. These machines sew together multiple layers of fabric and foam, producing a quilted design that not only enhances the look but also adds to the comfort and durability of the mattress.

From manufacturing mattresses using natural fibers such as cotton to more artificial materials such as polyester, these mattress quilting machines have to be flexible and efficient enough to handle all sorts of fabrics. The article examines how these machines handle a wide variety of fabrics, new technological developments, and how the type of fabric influences quilting performance.

The Role of Mattress Quilting Machines in Mattress Production

Mattress quilting machines sew together the top layers of fabric with internal padding, usually foam or fibers, to make up the top layer. This top layer provides not only comfort but also plays a very important structural role in giving the mattress shape that it maintains for a long time. This process mostly involves a difficult stitching pattern that binds the layers together, hence providing a plush and inviting surface.

Such quilting machines used in the production of mattresses must be able to work with various fabrics and padding to accommodate the diverse designs. Several types of fabrics enable producers to provide a large variation, from the very cheapest mattresses with a cover made from polyester to luxurious mattresses using the finest fabrics such as cashmere or organic cotton.

Types of Fabrics Used in Mattress Production

Types range from the fabric used in production to a price point intended for a specific mattress and target market. The most common types of fabrics used in the manufacture of mattresses include:

Cotton

Among the favorite fabrics of mattress manufacturers are cotton for its softness, breathability, and natural origin. Therefore, it is used in higher-quality mattresses, which value comfort highly along with eco-friendliness. Cotton, with its natural fibers, is more problematic to work with because it is less durable than synthetic fabrics, but also possibly due to stretching/shrinkage during the quilting process.

Polyester

Polyester is a resilient, man-made material used in numerous mattress quilts because it resists wear well and is inexpensive, making it easy to process. It does not wrinkle badly or shrink, therefore, that is good enough for mass production. Budget and mid-range mattresses are frequent hosts of polyester covers, which can also be combined with other fabrics in an attempt to increase the softness of the material.

Bamboo

Bamboo fabric has gained popularity within the mattress industry due to its eco-friendliness, moisture-wicking capability, and natural softness. Compared to polyester, this material is somewhat more delicate, it will have major advantages with regard to breathability and comfort. Quilting machines are, therefore, required to handle these bamboo fabrics with extra caution to ensure that in the process of quilting, they are not damaged.

Knitted Fabrics

The blend of knitted fabrics is based on cotton, as a rule, with some allowances for polyester, which was widely used for expensive mattresses. These kinds of fabrics are soft and very stretchy, which means they allow air to pass easily for the comfort of sleepers. However, it is their stretchiness that creates complications for quilting machines, which should pull the fabric with proper tension in the process of stitching in order not to create puckering or uneven stitching.

Jacquard

Jacquard fabrics weave in intricate patterns and are therefore very common in luxury mattresses. These fabrics are usually thicker and with more texture, therefore, their quilting requires special machines with stronger penetration force at their needles due to the increased thickness of the material.

Technological Advancements in Mattress Quilting Machines

Modern mattress quilting machines have undergone a sea change to work efficiently and effectively with a broad range of fabrics. Automation in innovation, control systems, and stitching has made the machines versatile, more precise, and capable of managing even very delicate or complex fabrics.

Automated Fabric Tension Control

One of the major challenges when one quilts fabrics of different types is managing fabric tension. Each fabric is different and therefore has different stretch properties. To prevent wrinkles, puckers, or distortion in fabrics, quilting machines need to have proper tension.

For this reason, today’s quilting machines come equipped with a computerized fabric tension control system to make sure that each fabric type is given the proper tension so smooth and even stitching occurs. This is particularly important when working on stretchy materials, such as knitted fabrics, or on fragile natural fibers, including bamboo and cotton.

Adjustable Needle Penetration

Not all fabrics require the same amount of force by the needle to quilt. Thicker materials, like jacquard fabrics or layers with heavy foam padding, require more needle penetration force for complete stitching. At the same time, thin materials like bamboo or cotton fabrics are easily damaged and require a lighter touch.

All modern quilting machines have variable needle penetration settings, thus, manufacturers can adjust the machine’s operation according to the kind of fabric at hand.

Multi-Needle Configurations

Multi-needle models allow many mattress quilting machines to quilt multiple layers of fabric and padding simultaneously. Quite useful for dealing with a number of more complicated mattress designs containing several materials on the top layer, for example. Capable of handling a wide variety of fabric types-from thick upholstery-grade materials to thin and light ones, these machines can switch between various needle sizes and configurations.

Programmable Stitch Patterns

Other developments of critical importance concern programmable stitching patterns that allow manufacturers to create intricate designs and patterns on the surface of the mattress. These computerized systems store a large number of stitch patterns and automatically alter these to compensate for the type of fabric being stitched and the visual effect sought.

Programmable stitching can create a precise, consistent pattern on a basic polyester blend fabric or the most expensive jacquard weaves, from gaudy to elegant, across the face of the mattress.

Challenges of Quilting Various Fabric Types

Despite the improvement in technology, quilting different types of fabric has several challenges. The producers have to be very conscious of each type of fabric to achieve the best performance during quilting.

Stretch and Puckering Issues

Knitted fabrics, as well as those made of polyester blends combined with spandex, will pucker or distort if not managed correctly upon quilting. These fabrics tend to stretch when under tension. If the fabric is stretched, it may lead to uneven stitches or distortion of the fabric.

Although modern quilting machines have successfully solved this problem due to automatic tension control, the operator still needs to pay close attention to avoid misalignment of the fabric.

Delicate Fabric Damage

Natural fibers like cotton or bamboo will be more vulnerable to damage during the quilting process. Fraying and fabric tears may result from an excessively high force of the needle or if the tension of the fabrics is set incorrectly. Such delicate fabrics, therefore, require operators to make careful adjustments to machine settings in order not to compromise the integrity of the fabric.

Thickness Variation

When quilting multiple layers of fabric and padding, especially with thicker materials like jacquard or heavy foam, the machine must be capable of adjusting to the varying thicknesses without skipping stitches or breaking needles. This requires precise control over needle penetration force and stitch length.

The Impact of Fabric Types on Mattress Performance

The fabric type used in its manufacturing process has a large impact on the comfort, durability, and performance of a mattress. The breathable fabrics like cotton or bamboo increase the airflow in the mattress and generally regulate the temperature, thereby making the sleeping experience rather comfortable for the sleepers. Synthetic fabrics, like polyester, are rather resilient and easy to clean, these features make the mattress more resistant to wear and tear.

Quilting machines must be versatile enough to handle all of these fabric types to create mattresses that meet consumer expectations in terms of comfort, durability, and aesthetic appeal.

Conclusion

Mattress quilting machines have indeed been designed to encompass a wide range of fabrics, from natural fibers like cotton and bamboo to robust synthetic versions like polyester, and intricately woven textiles like jacquard. Technological advancements such as automated tension control, adjustable needle penetration, and programmable stitch patterns have made these machines highly versatile, allowing manufacturers to produce high-quality mattresses with consistent stitching and intricate designs.

As the demand for different types of mattresses continues to grow, the ability of quilting machines to handle various fabrics efficiently will remain essential to the success of mattress production.

Связанные с ними товары