- Home » How Mattress Packaging Machines Improve Efficiency and Reduce Costs

Packaging of mattresses is an important stage of mattress manufacturing. Productive packing guarantees the protection of the mattress during transit and further embellishes its already important role in holding down operation costs towards improved productivity. Technological advancement has made mattress packaging machines quite an indispensable tool for manufacturers.

These machines speed up the process of packaging and minimize the cost of labor in the process while ensuring quality at the very last process in the entire process. In this article, we will explore how mattress packaging machines improve efficiency and reduce costs through various mechanisms.

The Role of Mattress Packaging Machines in the Manufacturing Process

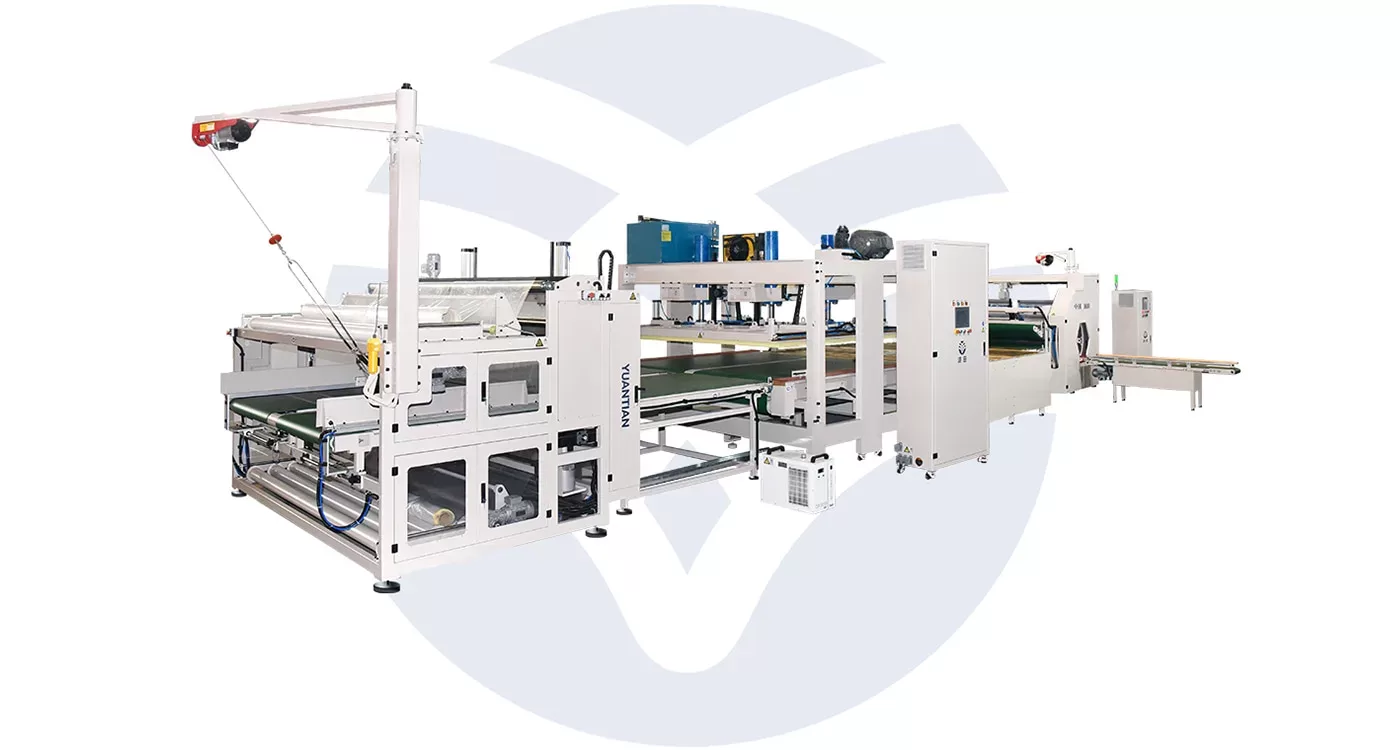

Mattress packaging machines are designed for wrapping, closing, and compressing mattresses automatically. Automation is essential at a large scale of production, where manual packaging could prove excessively time-consuming and prone to errors.

In fact, the integration of these machines will help to incorporate uniformity and standardization in the way of packaging, ensuring that every single mattress is securely and uniformly packaged.

Automation and Streamlining of Operations

One of the greatest benefits of a mattress packaging machine is found in the automation that it brings about. These machines can easily carry out tasks like putting the protective plastic around the mattress, compressing the size or volume, and sealing it ready for shipping.

In other words, automation not only makes the process of packaging speedy, but also ensures that every mattress is packaged in exactly the same way, reducing the chances of errors that can lead to breakage during transportation.

Consistency in Packaging Quality

Packaging can highly affect the control of product quality in the mattress business, which is one thing about consistency. Mattress wrapping machines make sure every product is wrapped and sealed with the same care, and it reduces the chance of wrecking the product through bad packaging.

This also influences the brand image and its value, as customers get their product in pristine condition, leading to a better customer experience, which automatically helps in reducing returns.

Cost Reduction through Mattress Packaging Machines

The prime motivational factor for investment in mattress packing machines is the potentiality of cost reduction. These machines have saved the labor costs to professionalize the reduction that is possible in material wastage, thus saving the capital of manufacturers in many ways.

Reduction in Labor Costs

Manual packaging involves a huge amount of labor. This can be expensive and ineffective, especially in a large production house. Mattress packaging machines do not require any manual labor for their packaging. Thus, manufacturers can use their workforce in other sections of production. This decrease in cost due to reduced labor is overpowering, which means increased profitability for the company.

Minimization of Material Waste

Manual packaging is highly prone to human errors, resulting in the overuse of packaging material. Machines for packaging mattresses are created in a way that they release only the required amounts of wrapping material to package each mattress securely. Such precision not only saves on the variable input but also aids in reducing wastage to support the sustainability program of that company.

Energy Efficiency and Cost Savings

The current mattress packaging machinery uses two or three times less energy compared to the old construction of mechanical models. The fall in the use of energy sharply reduces the operational costs. At the same time, the same level of energy efficiency is achieved by lowering the ecological footprints, thereby cost-effective and eco-friendly for manufacturers.

Enhanced Productivity and Operational Efficiency

Other than cost benefits, there are improvements in productivity and operational efficiency attributed to the mattress packaging machines. The automation of the packaging process has enabled manufacturers to have faster production and packaging of mattresses compared to before in order to meet the demand in the emerging market segment.

Faster Production Cycles

Due to the speed at which mattress packaging machines work, the production cycles are bound to be faster. Since it can really raise the rate of production, manufacturers can mount greater production volumes within a shorter time frame without compromising the quality of the mattresses. Faster cycles of production will also enable the manufacturers to service more orders and, therefore, increase their earning potential.

Reduction in Downtime

Delays in manufacturing are costly because they can lead to delays in production that may result in missed deadlines. A packaging machine for mattresses should be designed to run continuously since the costs of downtime in manufacturing can be high. The result is the manufacturer’s achievement of a continuous output since manufacturing is not interrupted.

Improving Product Protection and Reducing Returns

proper packaging assures protection to the mattress during transportation, mattress packaging machine will assure that each product will be properly wrapped and sealed, reducing the risk of damage that may lead to returns and more cost to the manufacturer.

Enhanced Protection during Transportation

Mattresses are big-sized products, and therefore such products need to be packed safely to avoid any kind of damage due to movement. A mattress packaging machine compresses the mattress and wraps it with durable packaging material to provide further protection from physical damage, moisture, and dirt.

This kind of protection assures a mattress is delivered in perfect condition at wherever it is meant to go, reducing significantly the cases of return of the product due to damage.

Reduction in Product Returns

Mattress product returns are, at times, the most expensive incidences to manufacturers as losses in sales and extra freight apply. Ensuring mattresses are properly packed, mattress packaging machines help reduce the incidence of returns. When the returns are minimized, manufacturers enjoy less expense while the customer enjoys better quality.

Adapting to Market Trends and Customer Preferences

The mattress sector is evolving and changing with new trends and customer preferences being introduced every other day. Mattress packaging machines provide the flexibility to adapt to these demands, thus allowing manufacturers to remain on competitive ground in this fast-changing environment.

Customizable Packaging Options

Customizable packaging options offered in modern mattress packaging machines can relatively be tailor-made to suit any given customer need or market trend.

For example, a manufacturer would opt for varied material colors and designs for the packaging so that when each type is opened, the experience awaiting the customer is distinct. This level of customization will allow the brands to establish a unique identity in a crowded market and create products that truly meet the needs of their diversified customer base.

Scalability for Growing Businesses

The more the business grows, the demand for the products increases, and a mattress wrapping machine is scalable. It will, therefore, be easy to scale according to the increased production capacities. This way, manufacturers are able to continue meeting customer demand even as their businesses grow, without having to make major additional investments in packaging infrastructure.

Conclusion

Investing in mattress packaging machines provides manufacturers with a strategic advantage in the competitive mattress industry. These machines not only improve operational efficiency and reduce costs but also enhance product quality and customer satisfaction.

By automating the packaging process, reducing material waste, and providing superior product protection, mattress packaging machines enable manufacturers to deliver high-quality products to their customers while maintaining profitability. As the industry continues to evolve, the adoption of advanced packaging technology will be key to staying competitive and meeting the demands of an increasingly discerning market.

Связанные с ними товары